Sheldon said:

It depends on the material, but I generally like to have the inlays fit snugly, and do NOT leave any slop. A light material into a light material, and .003 undersized is going to stick out like a sore thumb. Ivory into ebony, you can leave a little play to make getting the inlays in easier, because the glue lines will never show.

Be careful with coloring your epoxy, the pigment can bleed into lighter woods and stain/mark it.

Also, cutter size, material hardness, and even direction of cut (clockwise or ccw) can effect part and pocket size, so a thousandth clearance at the drawing could be too much or too little.... Try measuring the cut pockets and pieces to determine what kind of tolerances you will want to use, and how you can achieve them with consistency. That said, I pretty much ALWAYS cut my male pieces first, then do a test pocket in a piece of scrap before pocketing a cue. I rarely need to adjust them anymore though, because I have figured out how to be consistent.

I generally like 5 minute epoxy, since it sets up fast, and you dont need to clamp or rubberband loose fitting inlays to keep them from lifting before they set up. Mix very small batches and don't try to glue in too many at a time. For very complicated and difficult or very tight inlays, I use a 20 minute epoxy which gives me extra time to get them positioned.

Everything you mentioned is pretty much right on how I go about It, only difference is the machines We use. I don't think I could go any looser, because I have during test fitting, and I'm pretty sure I have them just snug enough. Now I do go by feel and test fits mostly, but My fits are the same providing I use the same routine on each pocket. I do alot of My fits By feel, so I'm used to achieving the same fits that way. It sounds like you and Murray fit them about the same as Me, but measuring all the way down to .001 to be sure might not be so easy for me with My manual machine, unless you guys know a better method that I'm not aware of.

I have had minor bleeding with the dye. I have a cue I won't sell now due to that, and It's a shame because it looked nice besides that. I was going into maple though, and It really shows on that. That was also with the thicker epoxy, and I still had some bleeding. The sad part is I probably did'nt even need the dye, and was just trying to be safe By using it. Some woods I have no problem with, but maple is not one of them.

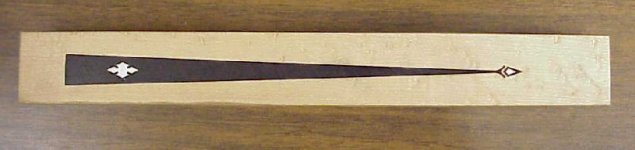

I go clockwise also, and cut My males first, even test fit them as Murray showed in the picture (beautifull fit & inlays btw). I go into the same woods I will be using, because as you mentioned different materials cut at different rates, and that's the best method I know of to make sure I have the correct stylus and endmill. You do aquire some minor waste, but better then finding out the hard way once I'm carving the cue up.

When I glue I usually only do 2 inlays at a time on opposite sides of each other.

A few people here already know I've been working with this machine for a while now. I actually started on It way before I started posting here, and built most of It from parts some time back, but Chris was a big help with some of the stuff I needed since Mine is a 1to1 also, and It's going on about a year since I have had it setup like I wanted it, altough I did do work with It before that. My point is I have had alot of hands on time with It, It works better then I expected, and I have had alot of trial and error with the learning curve, but in the end listening to you makes Me think I could have written Your post, that's how right on it is with the way I do things now also. it was learned from trial and error, so I like to think I could take that one to the bank if nothing else. does'nt mean I'm right though or that It's the best way. just what's been working for me.

I'm thinking I'm at about .001 like you and Murray, and I already know that what you mentioned about .003 is probably the same for me, and I honestly don't think I could get away with that much either, because the glue really shows on the sides for me. maybe other guy's machines are just tighter then Mine, I don't know, but where I'm at now works well, and I have never broken an inlay with that fit. Ofcoarse there's a first time for everything so I'm not saying It would'nt ever happen. Especially on sharper, thinner style inlays where anything can happen.

I do 2 styles due to the endmill/pocket limitations. 1- is I simply fit the inlay to the pocket, with that style I like to think I'm failry good at fitting them by now, but ocasionally even when the inlay looks tight after glueing, after I cut It down/trim the cue, I can see that possibly I did'nt sand the tip evenly enough all the way down, and may see a slight glue line on one side of the tip, even though the sides are good, and the points fit tight when I installed the inlay. I realize the issue, and strive to sand them perfect, but no matter how perfect they look, sometimes this still happens. If I'm using a glue that darkens, It only makes It stand out even more, so actually something that even just dried clearer would be slightly better then that. blending would be even better though.

The second style I do is to finish the pocket by hand to fit the inlay/male. for a long time I would fight with using exacto's and what ever small stuff I could find to work with. What I ended up doing and seems to work much better, is make my own tools on My grinder. I make them from several things, but one cheap way to go was those cheapo needle file sets you can pick up at the import tool places. They would always load up on me with metal and were basically no good anyway, so I made chisals out of the the flat files and cut My own profiles for what I needed. Then I grind an edge and hone them by hand. The result they're small sharp as a razor, and more ridgid then a thin exacto. It makes cutting the pockets in alot easier. The are very sharp, I know because I stuck one in My finger By accident, and It went in like butter

.

Thanks for the confirmation, sounds like my fittings are good, altough if anyone has any tips to rounding males, I may need some help there, also interested in what all different glues people are using.

Thanks Sheldon,

I would also like to thank everyone for their input, this has been good discusion, I love to hear each persons theories and preferences, as I gain knowlede from each one, and always a pleasure to share thoughts with others that have the same adiction as me

I realize My posts were long, so My appologies, those that know me know I have a hard time summing things up sometimes. I do try to, just not so good at it I suppose

Thanks Greg C