Has anyone ever purchased one of the mini lathes from harbor freight? I wanted to get another lathe for just tips and ferrules, but I called and asked them if there was an opening on the left side to put the shaft through and they said there wasn't. They didn't seem to intelligent on the phone, but i would have to drive two hrs to look at it. Any of you had any experience with this?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mini Lathe

- Thread starter chipperd

- Start date

They'll work but you'll need to make a steady rest to support the joint end of the shaft. For just tips & ferrules you can do no better than the excellent Travel Tipper mini lathe from Unique products. Hightower also has some very nice small lathes. These are designed for shafts and ready to go with accessories.

dave sutton

Banned

Figure on spending close to 800 by the time you are all said and done.

correct. for that price you might as well just but a hightower micro. better machine IMO easier to use and a hell of alot quieter

i had a mini lathe for HF and got a bed extension from littlemachineshop. i hated it sold it and luckily broke ever

For your consideration

For your consideration:

http://forums.azbilliards.com/showthread.php?t=133351&highlight=Professional+Cue+Repair+lathe

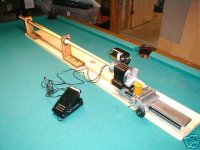

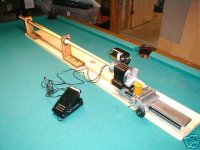

I also have a Basic model Photo attached:

Thanks a MIllion!!

Todd

For your consideration:

http://forums.azbilliards.com/showthread.php?t=133351&highlight=Professional+Cue+Repair+lathe

I also have a Basic model Photo attached:

Thanks a MIllion!!

Todd

Last edited:

Has anyone ever purchased one of the mini lathes from harbor freight? I wanted to get another lathe for just tips and ferrules, but I called and asked them if there was an opening on the left side to put the shaft through and they said there wasn't. They didn't seem to intelligent on the phone, but i would have to drive two hrs to look at it. Any of you had any experience with this?

I use one to put on tips and at tournaments I use it for tips, ferrules, shaft cleaning and polishing and wrapping. I got a Horrible fright 7X12 on sale for 359.00 or 389.00 or something in that neighbor hood. I also had a 15 or 20% off coupon so the lathe cost me something like 330.00 including tax, out the door. I made a rear steady rest and installed a quick change tool post and reworked the tailstock to use a lever for eaze of use. If you have access to tooling to make the rear tail stock to hold the shaft your ready to go. The other stuff is conveinent but not needed. The extended tail stock consists of a 1.25 roller bearing mounted in an aluminum block and mounted on an aluminum stand. I turned a delrin collet to fit in the bearing so that the shafts don't get marked. It cost me around 15.00 to make it. If I didn't buy the quick change tool post I wouldn't have 350.00 in this machine. With the tool post I've probably got less than 450.00. The hole through the head stock is a little larger than .750 and it has gearing to cut some threads and an auto feed. Here are some pictures of my set up.

Dick

Pool Hall Paul

Let em bank !

mini lathes

Chipperd,

I have a harbor freight mini lathe.They all have a thru hole it just has a cover over it with 2 screws.Like the others said you just need to rig up some kind of support on the end to support the shaft.I hope this helps.

Pool Hall Paul

Chipperd,

I have a harbor freight mini lathe.They all have a thru hole it just has a cover over it with 2 screws.Like the others said you just need to rig up some kind of support on the end to support the shaft.I hope this helps.

Pool Hall Paul

I use one to put on tips and at tournaments I use it for tips, ferrules, shaft cleaning and polishing and wrapping. I got a Horrible fright 7X12 on sale for 359.00 or 389.00 or something in that neighbor hood. I also had a 15 or 20% off coupon so the lathe cost me something like 330.00 including tax, out the door. I made a rear steady rest and installed a quick change tool post and reworked the tailstock to use a lever for eaze of use. If you have access to tooling to make the rear tail stock to hold the shaft your ready to go. The other stuff is conveinent but not needed. The extended tail stock consists of a 1.25 roller bearing mounted in an aluminum block and mounted on an aluminum stand. I turned a delrin collet to fit in the bearing so that the shafts don't get marked. It cost me around 15.00 to make it. If I didn't buy the quick change tool post I wouldn't have 350.00 in this machine. With the tool post I've probably got less than 450.00. The hole through the head stock is a little larger than .750 and it has gearing to cut some threads and an auto feed. Here are some pictures of my set up.

Dick

I, for one, am excited to see Dick posting photos. I've been anxious to see his shop and gear for a long time!

Paid about 300.00 for mine couple years ago