Hi,

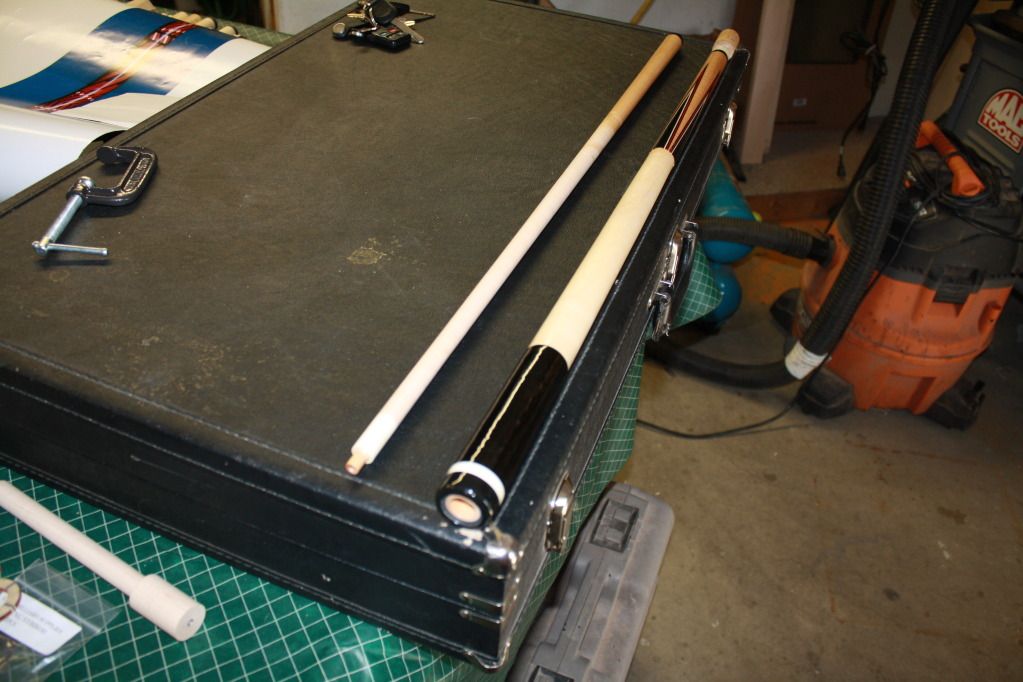

Here are some progress pics of a cue that I have been building for a Chicago Native and great pool player Tony G. This is Tony's second Esoteric Player that he designed all features of the cue for the custom order.

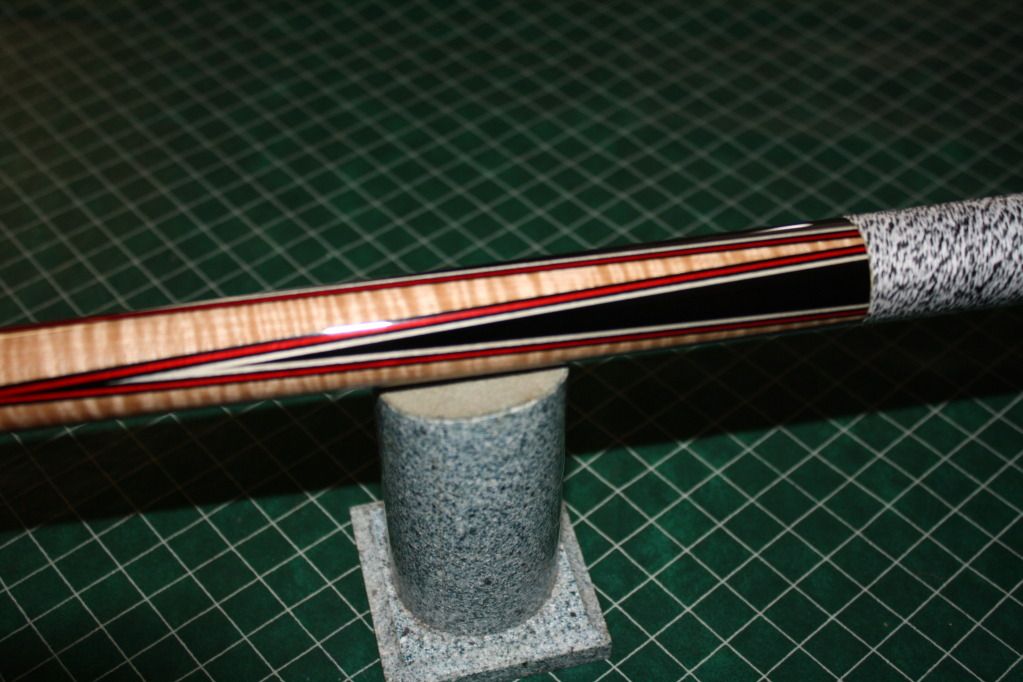

Tony is old school and likes his playing cues to be simple without a lot of bling. I offered to jazz it up with fancy rings and some inlays for him as a favor for this second cue order but he declined, opting for this simple player with a veneer stack mimicking one of his Bushkas.

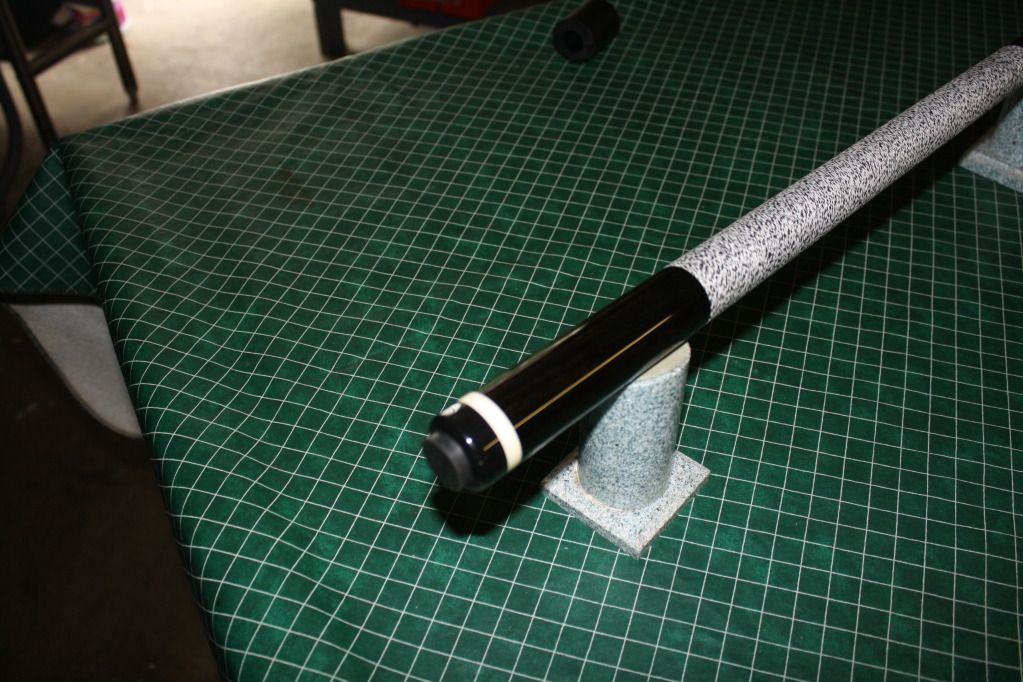

I will be completing this cue in a few days and can't wait to present it to him. I am going to be wet sanding and buffing the finish today and installing the wrap tonight.

Thanks for looking,

Rick G

Raw Materials for this Fully Cored Cue built on a 5 year seasoned 3/4" Maple Dowel utilizing Garolite Le for the shaft insert and pin embedment anchor.

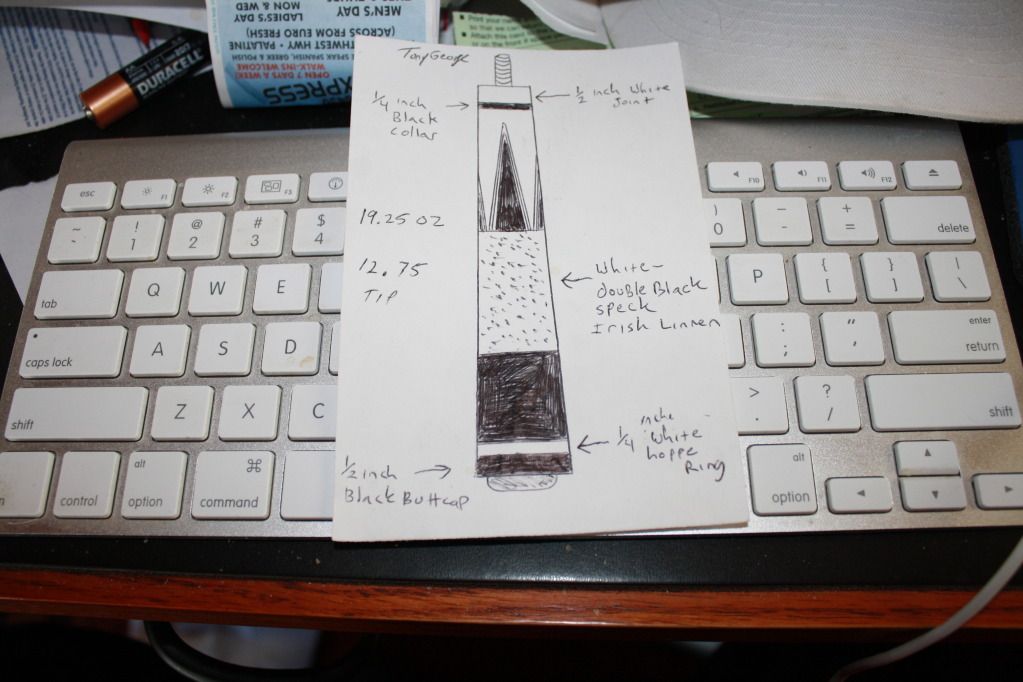

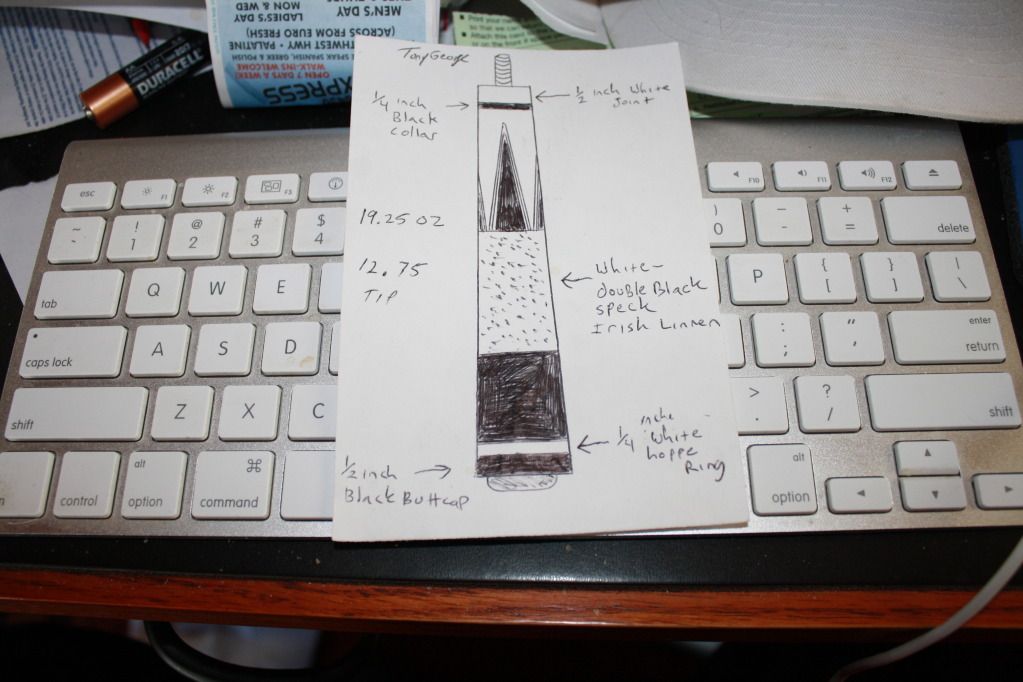

Tony's Design Submittal for Construction

Glue Clamping Point Veneers

Cue After Gluing Point Veneers

Turning in points and forearm on the butt saw machine. Ready for wood sealer and assembly

Here are some progress pics of a cue that I have been building for a Chicago Native and great pool player Tony G. This is Tony's second Esoteric Player that he designed all features of the cue for the custom order.

Tony is old school and likes his playing cues to be simple without a lot of bling. I offered to jazz it up with fancy rings and some inlays for him as a favor for this second cue order but he declined, opting for this simple player with a veneer stack mimicking one of his Bushkas.

I will be completing this cue in a few days and can't wait to present it to him. I am going to be wet sanding and buffing the finish today and installing the wrap tonight.

Thanks for looking,

Rick G

Raw Materials for this Fully Cored Cue built on a 5 year seasoned 3/4" Maple Dowel utilizing Garolite Le for the shaft insert and pin embedment anchor.

Tony's Design Submittal for Construction

Glue Clamping Point Veneers

Cue After Gluing Point Veneers

Turning in points and forearm on the butt saw machine. Ready for wood sealer and assembly

Last edited: