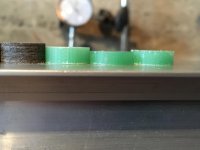

So I received the two SPC tips I ordered today. Both of them thicker than the first one I got sent. And both of them are different thickness from each other.

On to the install on my jump cue. Pretty much the same as before. But one thing I noticed while cutting, and the reason I quoted that picture. Too fast of a cut or too deep starts to fracture the edge of the tip. All those white spots on that Air2 SPC are mini fractures at the seems of the weave. I never noticed those spots occurring during the intial break cue install, but I also took way longer to install that one than my jump cue.

After experiencing those fractures from the install process, I would say that even a lathe isn't going to install the SPC better than by hand. It'll just be way quicker. I don't know what process Kimmo used, and I won't venture a guess either. I will say that I will definitely be getting some diamond grinding bits for a dremel to do installs on G10/SPC tips and any other super hard tip from here on out.