You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

round vs" pointy " points

- Thread starter bbb

- Start date

bbb said:what's the difference?

Other than the fact that one is sharp and the other is round? *LOL*

Usually your rounded points are a result of being made with a CNC machine.

Personally...CNC'ed points make me want to wretch. But that's just me.

This may help................

http://forums.azbilliards.com/search.php?searchid=2019891

http://forums.azbilliards.com/search.php?searchid=2019893

edit........to better help serve those who need help..........

http://forums.azbilliards.com/search.php?searchid=2019891

http://forums.azbilliards.com/search.php?searchid=2019893

edit........to better help serve those who need help..........

Last edited:

BarenbruggeCues said:

May not. Links don't work.

Rounded points were likely done with either a CNC or a Pantograph. That doesn't mean that all CNC or Pantograph points are round. It's also possible that if the tips of the points don't appear sharp that the bottom edge of the points or veneers wasn't a sharp 90 degree angle when put in.

I'm not even going to debate which is better. I do one type, somebody else may do another.

I'm not even going to debate which is better. I do one type, somebody else may do another.

ELBeau said:Unless you're asking about "butterfly" points, which are different altogether.

Never thought about that.........now I have to look up another search for them.

BarenbruggeCues said:Never thought about that.........now I have to look up another search for them.

LOL Good man!

Well, all three of the links worked earlier.........

Guess they'll just have to "Search this Forum" with these three phrases...

sharp points

rounded points

butterfly points

#!*%$#@! search function anyway...............

Guess they'll just have to "Search this Forum" with these three phrases...

sharp points

rounded points

butterfly points

#!*%$#@! search function anyway...............

Sharp points = Old school.

Round points = New school.

It all depends on what school are you. It most probably takes more inate skill to do sharp points the old school way, but I feel that CNC inlays/points are a little more versatile in there design and do require a whole different type of skill, drafting and CNC programming.

Personally, most CNC cues with round points do appear a little lazy though. I think any respecting cue builder should at least go back and sharpen them up some, but that might take that special touch that it takes to be a great cue guy and not just a mass produced production/custom cue. Just my opinion.

I like em' both.

Regards,

Frank

Round points = New school.

It all depends on what school are you. It most probably takes more inate skill to do sharp points the old school way, but I feel that CNC inlays/points are a little more versatile in there design and do require a whole different type of skill, drafting and CNC programming.

Personally, most CNC cues with round points do appear a little lazy though. I think any respecting cue builder should at least go back and sharpen them up some, but that might take that special touch that it takes to be a great cue guy and not just a mass produced production/custom cue. Just my opinion.

I like em' both.

Regards,

Frank

Gerald said:A guy I know has some beautiful Shons but the round points just turn me off. But obviously they don't bother him. Different strokes.

Schon's are more of a production cue. Unless touched up with an exacto knife, CNC'd points and inlays will usually only be as sharp as the radius of the tooling used to make the pocket. The larger the tool, the stronger so this equates to much faster production times but also, a much larger radius. Using smaller radius tools is much slower but the points are much sharper without any additional touch up work.

Dick

I don't understand why people want to compare V-points to the crappiest cnc work they can find. A CNC in capable hands will open up a whole new world of options and possibilities.

V-points can be really sweet too though, but don't compare good traditional work with crappy cnc work.

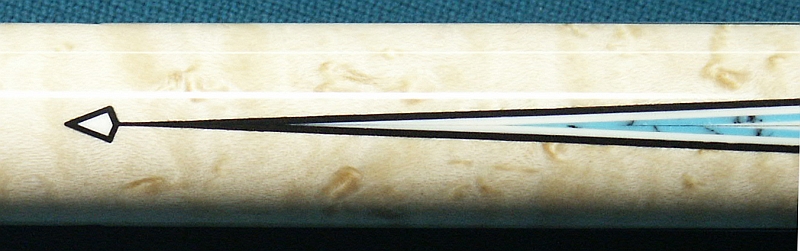

Turquoise, Ivory, and silver Veneers:

Ebony/Ivrory/Turquoise

Maple/Lapis/Cocobolo

Ivory/Malachite

V-points can be really sweet too though, but don't compare good traditional work with crappy cnc work.

Turquoise, Ivory, and silver Veneers:

Ebony/Ivrory/Turquoise

Maple/Lapis/Cocobolo

Ivory/Malachite

bbb said:what's the difference?

Round- usually made by coming in from on top of the forearm with an end mill. This produces a radius at the end of the point. Normally done on a mill or pantomill, what drives it makes no difference.

Sharp- Usually made by cutting a tapered 90 deg pocket into the forearm starting on edge at joint end and cutting inward toward centerline while moving to the A joint end of the forearm. This can be done various ways, shaper, mill, lathe, CNC mill etc using a straight endmill, shell end mill, 90 deg side cutter bit, 90 deg V bit or table saw blade, etc.

I do all my V bottom points on a CNC mill. A mill is a mill, what moves the X,Y, Z axis has nothing to do with whether the point is sharp or not.

Kenny Murrell

Cheater!!! :grin-square: :grin-square:Kenny said:I do all my V bottom points on a CNC mill. A mill is a mill, what moves the X,Y, Z axis has nothing to do with whether the point is sharp or not.

Sorry, couldn't resist.....

Tools is tools. :wink: