middleofnowhere

Registered

Want to do some cf shafts. Is there a good supplier for shaft stock?

Thanks

Thanks

I don't think carbon fiber tubes are as finite a resource as desirable lumber. If memory serves, wood sources are what triggered that "rule," to begin with.I guess all the forum rules are null and void now Sheesh!

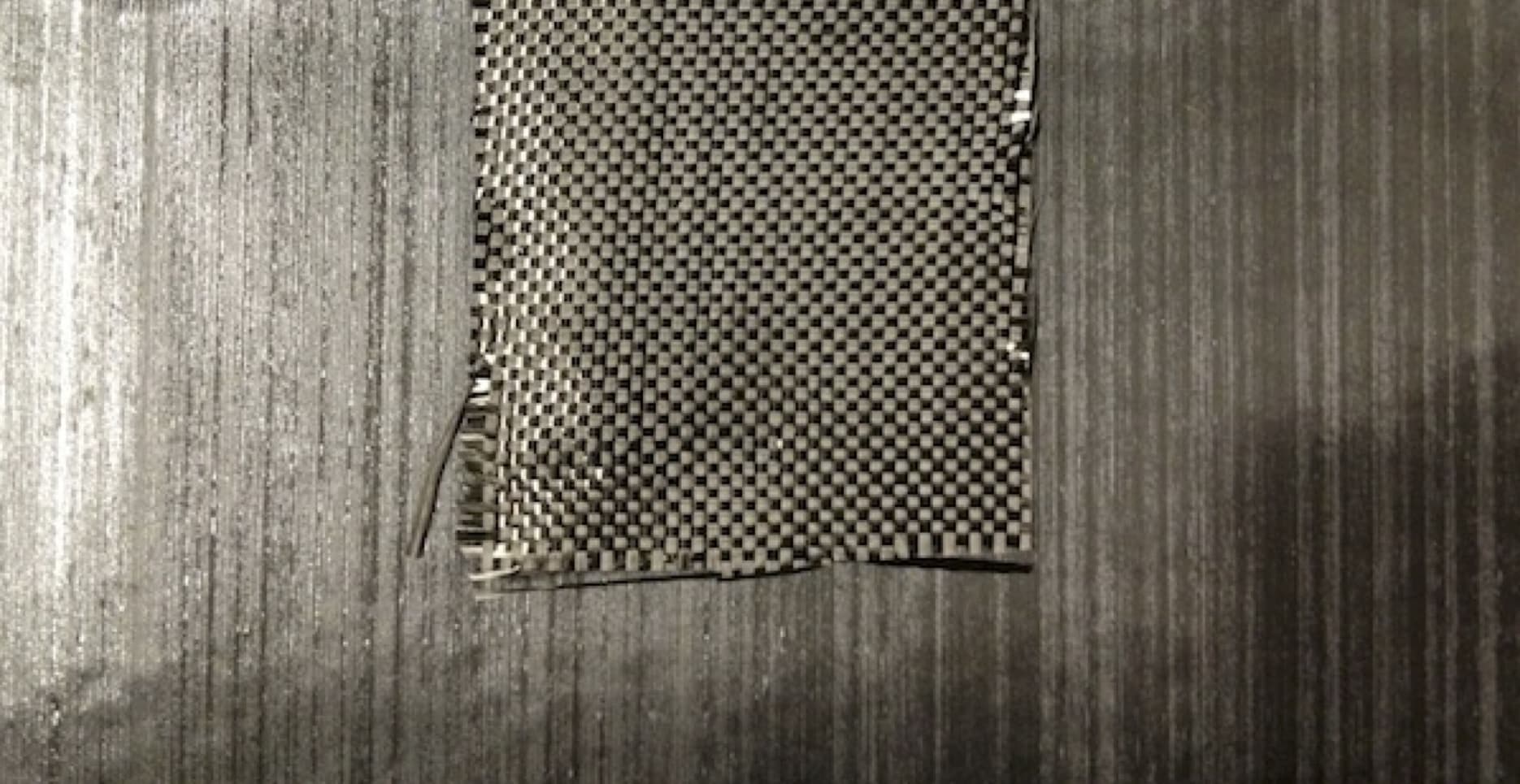

Yes there is a coating on them so you don't see or feel the weave pattern. But even I do not know exactly what they coat them with.Speaking of blanks, Chris H mentions his are finished. I'm curious that that finish is. Some people say it means the sanding and polishing. In Chris's case I got the impression there was some type of finish on the cf. Anybody know?

Yes there is a coating on them so you don't see or feel the weave pattern. But even I do not know exactly what they coat them with.

What is the correct name for the pattern going through Carbon Fiber?I haven't seen a cf shaft that is woven. Woven cf is mostly used in applications where the expected forces are in many directions or are unpredictable, or it is used for lower manufacturing cost of semi complex designs. Woven cf is weaker than the biased lay-up that products like golf clubs, fishing rods, pool cues, and airplane parts use. You won't see a weave on a 777 wing (I can say with absolute certainty, I helped design the machinery that builds the wings).

What is the correct name for the pattern going through Carbon Fiber?

Hang on there big dog, we are not all not engineers here so please slow down and let us comprehend your philosophy so we are all on the same page lolThe only pattern I see in my CF blanks is a barely noticeable radial pattern, almost like curly maple. It is not a pattern of the CF fibers, but likely a relic of how they form the CF on the blank or how they clamp it. The pattern appears to mostly be in the resin binder.

The shaft blanks I have used seem to be completely unidirectional, longitudinal lay-up. In more advanced structures, layers are built with the fibers running on a specific bias depending on how the structure needs to resolve forces.

Hang on there big dog, we are not all not engineers here so please slow down and let us comprehend your philosophy so we are all on the same page lol

www.applemanbicycles.com

www.applemanbicycles.com

View attachment 883094

Home

PEASPER International Ltd. is a carbon fiber tube manufacturer offering custom OEM/ODM tubes (round, square, tapered).www.carbonfibercue.com

I agree, would be a new learning curve, because they hit harder , so the learning curve gets bigger, trying to hold the cue ball in control. I went from wood to cf and that's an adjustment curve i don't like. What comes next after carbon fiber? Will Ai do it all for us with voice recognition Enjoy your game everyone. !i've only seen these 'weave finish' shafts on j/b cues or lo-end players. never seen a decent play shaft made this way. every decent-to-good players have all been matte finish.