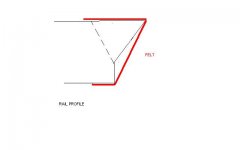

I recently got a good deal on a chinese made pool table (I know, I know - you get what you pay for!) Anyway  I am ready to felt the rails and noticed a peculiarity. The bottom portion of the rail below the the cushion is not beveled to continue the angle of the cushion down to the playing surface. Instead there is a vertical surface. The problem is when I stretch the felt to staple underneath there will be a gap behind the felt in this area. Is this common or was there a step missed in the manufacturing? Would the felt be ok installed in this manner? Should I glue it to the vertical face to follow its profile? Or is this just unacceptable and I need to find a woodshop to bevel this to follow the angle of the cushion? Appreciate any feedback!!

I am ready to felt the rails and noticed a peculiarity. The bottom portion of the rail below the the cushion is not beveled to continue the angle of the cushion down to the playing surface. Instead there is a vertical surface. The problem is when I stretch the felt to staple underneath there will be a gap behind the felt in this area. Is this common or was there a step missed in the manufacturing? Would the felt be ok installed in this manner? Should I glue it to the vertical face to follow its profile? Or is this just unacceptable and I need to find a woodshop to bevel this to follow the angle of the cushion? Appreciate any feedback!!

Attachments

Last edited: