I am about ready to glue some veneers together. I am a rookie at this so I would take any suggestions for glueing procedures. THANKS

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

veneer question

- Thread starter bob_bushka

- Start date

I am about ready to glue some veneers together. I am a rookie at this so I would take any suggestions for glueing procedures. THANKS

I have 2 pieces of 8/4 maple 12X16 inch that has 6 bolts glued upright through one board, around the circumference. I put down a piece of Saran wrap and then lat the bottom veneer in the center. I then pour on some West System epoxy and use a 1.5 inch foam brush to spread it out well covering all areas. I then put on my next veneer and repeat the preceding procedure. I do this until all of the veneers are glued and stacked then I put another piece of Saran wrap on top. I then take the other piece of maple, that has holes drilled in alignment with the bolts in the bottom board and set this on top of the veneers like a cover. I then put on large fender washers and nuts and try to tighten the bolts equally so that one side isn't pulled down and the other up. I then put the "sandwich" into my hydraulic press and put pressure in the center of the flat boards, come back the next day and remove the Saran wrap and on the band saw I square everything up and then do what ever it is that you need the veneers for.

Dick

I have 2 pieces of 8/4 maple 12X16 inch that has 6 bolts glued upright through one board, around the circumference. I put down a piece of Saran wrap and then lat the bottom veneer in the center. I then pour on some West System epoxy and use a 1.5 inch foam brush to spread it out well covering all areas. I then put on my next veneer and repeat the preceding procedure. I do this until all of the veneers are glued and stacked then I put another piece of Saran wrap on top. I then take the other piece of maple, that has holes drilled in alignment with the bolts in the bottom board and set this on top of the veneers like a cover. I then put on large fender washers and nuts and try to tighten the bolts equally so that one side isn't pulled down and the other up. I then put the "sandwich" into my hydraulic press and put pressure in the center of the flat boards, come back the next day and remove the Saran wrap and on the band saw I square everything up and then do what ever it is that you need the veneers for.

Thanks I think I get it but I have no hydraulic press except for my fat ass! lol

I don't have a hyd. press either. I just use a C clamp in the middle of my pressing blocks. I also bolt them together on each end with a carriage bolt, fender washers and wing nuts. I use 2) 3x3 hardwood blocks whatever length you need for your application. I do recommend running them through your planer or joiner to assure they are perfectly flat surfaced so they will apply even pressure on your glued veneers. It works good for me. Good luck!

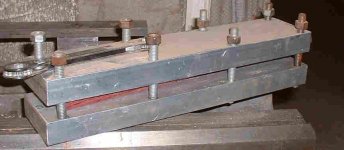

I made a veneer press similar to the ones shown here. It has two blocks that allow you to press two sets of veneers at one time and provides even clamping pressure. The large Jorgenson clamps provide all the clamping pressure you will ever need. The glue I use is called Better Bond Cold Press Veneer Adhesive, using a roller to get a thin even coat.

Bob Danielson

www.bdcuesandcomix.com

Bob Danielson

www.bdcuesandcomix.com

Attachments

dave sutton

Banned

i use a large zip lock bag to not make a mess and keep when everything from movng

thanks lee

thanks lee

Last edited:

I like to use multiple C Clamps on two pieces of flat aluminum bar with wax paper between each set of veneers.

I've been looking around for some off cut aluminum plate. I need at least 10 inch wide as when I glue up my veneers I do them in what ever the width of the veneer is and then trim off the over size. The way I do my veneered points I need the finished, glued up sheet to be 1 inch wide for each point. 4 inch = 4 point, 6 inch = 6 point and so on.

Dick

dave sutton

Banned

I have a large table clamp if anyone wants it. Ill let it go cheap. Depending on shipping. I got it from grizzly for like 100$ shipped

its 18'' between legs this is what i used before i got the hydrolic press

its 18'' between legs this is what i used before i got the hydrolic press

Last edited:

Some one inch plate a foot long by 10 inches wide will cost you and arm and a leg. You might even have to throw in the shoes and gloves. That is why I use 3 inch aluminum. It is easy to find and one row of clamps gives nice even pressure. But I do have to cut my veneers in strips that way.I've been looking around for some off cut aluminum plate. I need at least 10 inch wide as when I glue up my veneers I do them in what ever the width of the veneer is and then trim off the over size. The way I do my veneered points I need the finished, glued up sheet to be 1 inch wide for each point. 4 inch = 4 point, 6 inch = 6 point and so on.

Dick

dave sutton

Banned

i just spend the 200$ and got lee's plates. perfectly machined heavy duty springs 12''x8''

200$ for the plates

100$ hydrolic press at harbor freight

300$ for a veneer press total is not that bad...

no worries

200$ for the plates

100$ hydrolic press at harbor freight

300$ for a veneer press total is not that bad...

no worries

i just spend the 200$ and got lee's plates. perfectly machined heavy duty springs 12''x8''

200$ for the plates

100$ hydrolic press at harbor freight

300$ for a veneer press total is not that bad...

no worries

thats not bad dave, i only live about 1 hour from u.i will drive to your house 20$ in gas and use your press. ill make out like a bandit lol