If 2 different table mechanics/installers put a new cloth on say a 9ft pool table, and they both install the same cloth, yet the one person can't stretch the bed cloth as tight as the other installer, does that make the weaker installer wrong?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

When is cloth installed new, tight enough?

- Thread starter realkingcobra

- Start date

Here's the pictures everyone one sees when the job is done as a way of saying, "look at the work I did, aren't I good"

I recovered this 9ft Diamond ProAm at Brothers Billiards yesterday for Shane and Earl to play on this weekend.

I recovered this 9ft Diamond ProAm at Brothers Billiards yesterday for Shane and Earl to play on this weekend.

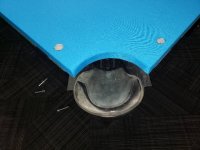

Here's the pictures you DON'T see.

Attachments

-

20220224_174110_resize_20220225_092454.jpg54.2 KB · Views: 234

20220224_174110_resize_20220225_092454.jpg54.2 KB · Views: 234 -

20220224_174102_resize_20220225_092455.jpg49 KB · Views: 234

20220224_174102_resize_20220225_092455.jpg49 KB · Views: 234 -

20220224_174041_resize_20220225_092456.jpg29.5 KB · Views: 246

20220224_174041_resize_20220225_092456.jpg29.5 KB · Views: 246 -

20220224_174114_resize_20220225_092454.jpg40.5 KB · Views: 235

20220224_174114_resize_20220225_092454.jpg40.5 KB · Views: 235 -

20220224_174137_resize_20220225_092454.jpg37.5 KB · Views: 248

20220224_174137_resize_20220225_092454.jpg37.5 KB · Views: 248 -

20220224_174144_resize_20220225_092454.jpg43 KB · Views: 247

20220224_174144_resize_20220225_092454.jpg43 KB · Views: 247 -

20220224_174148_resize_20220225_092453.jpg35.4 KB · Views: 232

20220224_174148_resize_20220225_092453.jpg35.4 KB · Views: 232 -

20220224_174659_resize_20220225_092453.jpg19.5 KB · Views: 224

20220224_174659_resize_20220225_092453.jpg19.5 KB · Views: 224 -

20220224_174652_resize_20220225_092453.jpg25.6 KB · Views: 212

20220224_174652_resize_20220225_092453.jpg25.6 KB · Views: 212 -

20220224_174645_resize_20220225_092453.jpg34.7 KB · Views: 235

20220224_174645_resize_20220225_092453.jpg34.7 KB · Views: 235

More of what you DON'T see.

Extremely good question. I was talking to a co-worker yesterday and he was describing the results of a cloth install he aided with. Him and the owner of the room, (not an actual mechanic) installed 860 on one of the room's GCx's, (staple method). Apparently a couple of days afterward, moderatey pushing your hand into the surface would bunch up the cloth. I simply told him that they didn't stretch it enough, (didn't bother mentioning the indexing I saw in the video). His reply was that they couldn't have done it any tighter. However they pulled the staples and 're-stretched'If 2 different table mechanics/installers put a new cloth on say a 9ft pool table, and they both install the same cloth, yet the one person can't stretch the bed cloth as tight as the other installer, does that make the weaker installer wrong?

Now I will add that the room owner is a bear of a man so I don't doubt his overal strength. That said, strength doesn't necessarily translate to effort.

So was the room owner "wrong"...? Well imo he was wrong in thinking that he could do a good job, because quite frankly the table overal wasn't done very well....lol. The bigger question is how tight is tight enough...? Should mere mortals expect to have to perform a 're-stretch' or can they managed a decent result in a single effort...? I haven't made an attempt yet, so will simply following the indexing process result in an adequate installation..?

I assume that this is why the Simonis DVD gives an actual stretch dimension. That way it doesn't matter if the individual is strong enough to stretch by hand or if they must use a tool. Its not just strength either, I had only about 2" of extra cloth on my GC, I doubt that there was anyway someone would be able to grasp that small of a piece of cloth and stretch it to Simonis' dimensions. I made a tool to assist me in getting the proper amount of stretch.Extremely good question. I was talking to a co-worker yesterday and he was describing the results of a cloth install he aided with. Him and the owner of the room, (not an actual mechanic) installed 860 on one of the room's GCx's, (staple method). Apparently a couple of days afterward, moderatey pushing your hand into the surface would bunch up the cloth. I simply told him that they didn't stretch it enough, (didn't bother mentioning the indexing I saw in the video). His reply was that they couldn't have done it any tighter. However they pulled the staples and 're-stretched'

Now I will add that the room owner is a bear of a man so I don't doubt his overal strength. That said, strength doesn't necessarily translate to effort.

So was the room owner "wrong"...? Well imo he was wrong in thinking that he could do a good job, because quite frankly the table overal wasn't done very well....lol. The bigger question is how tight is tight enough...? Should mere mortals expect to have to perform a 're-stretch' or can they managed a decent result in a single effort...? I haven't made an attempt yet, so will simply following the indexing process result in an adequate installation..?

Our local Mechanic was doing a recover on couple of tables today.

Though job to do it right. If you have never seen done, it intresting to see process.

Though job to do it right. If you have never seen done, it intresting to see process.

Although I haven't gotten that far yet. I've almost already resigned myself to the fact that I will need to do similar.I assume that this is why the Simonis DVD gives an actual stretch dimension. That way it doesn't matter if the individual is strong enough to stretch by hand or if they must use a tool. Its not just strength either, I had only about 2" of extra cloth on my GC, I doubt that there was anyway someone would be able to grasp that small of a piece of cloth and stretch it to Simonis' dimensions. I made a tool to assist me in getting the proper amount of stretch.

By chance do you have a pic of the tool in question?

I just took a pair of Vise Grips that had worn out teeth in the jaws and welded a couple of 1 1/2" x 3" strips of 3/16" steel in the jaws. They are essentially a set of duck bill pliers. Kinda like the ones below but my jaws are parallel with each other when closed.Although I haven't gotten that far yet. I've almost already resigned myself to the fact that I will need to do similar.

By chance do you have a pic of the tool in question?

More of what you DON'T see.

View attachment 630665View attachment 630666View attachment 630667View attachment 630668View attachment 630669[ATTACH

Attachments

Notice how nice the side pocket work is???^^^^^^^^^^

Might be ok if you want to raise the rail height at the side pockets. Looks a bit loose, too. I don't think bunching the cloth up under the rail like that is a good idea. I've seen it done like that before, but it's rare for a reason.Notice how nice the side pocket work is???^^^^^^^^^^

That’s not yours is it? I’m pretty sure you have a GC I. I’ve never seen folds on side pockets that weren’t on the facings.Notice how nice the side pocket work is???^^^^^^^^^^

Like I showed in the videos, if you clamp the cloth to one side of the slate, for example a Diamond 7ft. When you stretch the cloth across the slate as tight as you can, and put a pencil mark at the edge of the slate, then let it relax back. Measure that maximum stretch. Let's say you come up with 2 3/8" using Simonis 860HR tour blue. Subtract 3/4" for the working stretch, that leaves you 1 5/8" inches for the working stretch. You'll get that 3/4" back once you stretch the cloth end to end, because when you do that stretch it trys to stretch the cloth side to side but it can't because by then both sides have been attached, so what that end to end stretch does is tighten the side to side stretch up even more.I'll ask the expert since I don't remember it being on the DVD. What's the index of 860HR? How does table size vary the index dimension?

Good looking work Glen.

Now, you have a known stretch for a certain cloth, on a known side of slate. So now you need to recover a 9ft with the same cloth, ok, this is how you figure out the stretch index without having to go through the clamping, stretching, marking, and measuring process again.

Take that known 1 5/8" stretch, divide that by the width of the slate, being 47".

That breaks down to 1 5/8"÷47"= .0345744681 stretch per inch, now multiple that by the 57" wide 9ft slate and you working stretch becomes 1.9707 inches, or basically 2" side to side.

When you install that 9ft bed cloth, if you happen to notice you have some slight stretch shadows on the stretch to side, A) either you're not stretching hard enough from the side pocket to the corner pockets lengthwise, or you're not strong enough to make that stretch, so, B) back off an 1/8" in your side to side stretch, until you've done enough 9fts to know for sure what your stretch index is.

This formula works for any make of cloth, on any size of table, but, keep in mind when dealing with Simonis cloths, some colors like Green don't stretch as much as the Tour Blue does, so do a simple stretch test first if you're not use to working with that color of cloth.

For installing the new Predator cloth, you can throw all this out the door, because it don't work with their cloth.

The Predator cloth has to be installed loose like snooker cloth, pulled just tight enough to get the wrinkles out and thats it. And, it'll have to be re-stretched several times before replacing it.

I personally won't work with it, no matter what the customer offers to pay.

That’s not yours is it? I’m pretty sure you have a GC I. I’ve never seen folds on side pockets that weren’t on the facings.

Definitely not mine, you have a good memory, I do in fact have GCI.

I was mostly referring the the side pocket fold, I'm no table mechanic but something appears wrong to me when you cant shoot a ball down the rail past the side pockets without the corner of the fold sending the cue ball to mid table. That's not how my rails look that were professionally covered. Besides that you can feel the bed cloth bunch up under your hand when you slide your hand into place.Might be ok if you want to raise the rail height at the side pockets. Looks a bit loose, too. I don't think bunching the cloth up under the rail like that is a good idea. I've seen it done like that before, but it's rare for a reason.