dan b

what do you mean "table score"

what do you mean "table score"

Call me, 702-927-5689

Edit: I had the wrong link. This one is correct and only 10 seconds long.

https://www.youtube.com/watch?v=ChsSttyclMQ

9 rails on my GC per RKC's test, for reference.

..ha, whaaateveeer, but still, when you're in the neighborhood, I can put you up for the night,

standard house bet, my game, you break...

Several things I'm seeing in your videos.stupid questions.... arent the cushions already glued to the rails from the manufacturer?

this is not something the mechanic does on an install right?

YES, mfg glued.

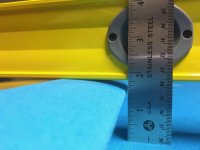

also wondering if I have the correct profile on these rails.

Per videos, they look correct.

or if they were applied correctly. I can see a line through the felt on top and feel a transition on the bottom

That line is normal to poor cloth installation, they pressed the feathers too deep.

We're doing our best... can't ask for much more.Until he takes an end rail off and takes pictures so i can see what he sees, i don't know what else to sugest.

First rail removal seems difficult, thereafter piece of cake. First time will take you several hours, thereafter 2 tops.Hi thanks for the response.

the particle board you are seeing is the backing material for the slate.

the rail beneath that should be solid wood.

I didnt want to take a rail off myself. may never get if back on correctly.

alittle advice here and maybe I can do this on the weekend.

OH, the cushion to wood line.btw thie line I see through the cloth seems to be between the rubber and the wood (not feather stip). so I thought the rubber cushions were glued on to high

Ya, caught that the moment you posted this.Hi thanks for the response.

the particle board you are seeing is the backing material for the slate.

the rail beneath that should be solid wood.