This is an older Diamond Professional 9ft, with a standard 30mm 3 piece slate and no leveling system. I've taken pictures of the complete process of converting it to a steel plate joined set of slates that no longer require being mounted to the frame of the table with slate screws like all 3 piece slates are mounted. First thing that has to be done is to remove the slate backing, in this case....all the MDF on the back side of the slates, which is used to provide some place to put staples to install the bed cloth....but, not anymore on this table

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 piece slate steel plate joined and leveling system added as well.

- Thread starter realkingcobra

- Start date

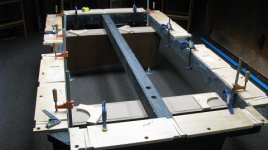

Now to add the frame work for the slates to sit on when they're set on the frame of the table, and to have somewhere to mount the wedge leveling system. In doing this, you build it on top of the slates to match them perfect, then transfer everything to the frame of the table afterwards.

Attachments

Time to take the slates apart, turn them over and profile the pocket plates, then transfer them to the frame of the table.

Attachments

So, now to answer anyone's questions about should they get a Diamond with a 3 piece slate instead of a one piece, feeling that the one piece slate may be a better slate...it don't matter anymore, the 3 piece steel plate joined slates are what Diamond now offers because it works great. The steel plate joined 3 piece slates can even be installed in a ProAm or Smart Table, fliped up into a cart, transported and installed...and the seams will never come apart...until someone takes them apart, because they'll never come apart on their own, not even if you climb up on the table to hang a light...and walk all over the playing surface while you're doing it

Here's what the pockets look like when finished, not a single staple has been used to install the bed cloth, not even in the pockets.

So how does the cloth get held in place and stretched?

how much would you charge/ did you glue the felt on the slate?

I only install the bed cloth using my stretch/gluing system, even if the slates have a backer board for stapling the cloth down. Cost is subjective

So how does the cloth get held in place and stretched?

The cloth is stretched into the pockets, and under the pocket shelf, then glued in place with the FB10 I use, then the pocket plates are bolted in place to finish off the pockets, and to provide the drop pockets a place to be attached, as well as providing additional support to hold the pocket flaps tightly in place.

Do you provide table services for customers in new jersey?