I purchased a Defy carbon shaft recently and have some issues that I'd like help understanding. The first was that screwing the shaft onto the butt (a 1983 Richard Black with 3/8x10 pin) was very difficult. It was tight from the start, but got harder and harder to twist on the further the pin was in the shaft. Once all the way in, I chalked the tip and got ready for my first shot with the shaft. As I stroked it getting ready to shoot, I felt something loose inside the shaft that would move back and forth as I stroked. That's the second issue. My first thought was a weight was inside and it had come loose. Looking online I found that a few others had the issue of something inside moving back and forth. McDermott stated that it was something glued in place in the shaft that is part of their dampening system. I contacted the seller and he agreed to send me another shaft and deal with McDermott regarding the warranty/repair of the shaft.

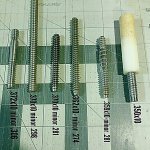

The things that I'd like to understand are is it unusual that the shaft was so difficult to screw onto the butt? I am familiar with trying to screw incorrect threads together, but if that were the case there is no way that it could have been screwed all the way in. The shafts for Richard Black cues only came in 3/8x10 and 5/16x14. My butt pin protrudes almost exactly 1" from the butt base and there are 10 threads showing, so I am sure that it cannot be 14 TPI. I think possibly the fact that the insert is some sort of plastic that it's supposed to be a tight fit, and mine is just a little tighter than normal due to mfg tolerances. Or, possibly it's made to initially be tight and would get easier over time. My other question, is it possible that the pin pushed the dampening insert loose (by extending too far into the shaft) and that is partially responsible for why it was so hard to twist when the pin got close to being fully inserted. Any help with these would be greatly appreciated.

The things that I'd like to understand are is it unusual that the shaft was so difficult to screw onto the butt? I am familiar with trying to screw incorrect threads together, but if that were the case there is no way that it could have been screwed all the way in. The shafts for Richard Black cues only came in 3/8x10 and 5/16x14. My butt pin protrudes almost exactly 1" from the butt base and there are 10 threads showing, so I am sure that it cannot be 14 TPI. I think possibly the fact that the insert is some sort of plastic that it's supposed to be a tight fit, and mine is just a little tighter than normal due to mfg tolerances. Or, possibly it's made to initially be tight and would get easier over time. My other question, is it possible that the pin pushed the dampening insert loose (by extending too far into the shaft) and that is partially responsible for why it was so hard to twist when the pin got close to being fully inserted. Any help with these would be greatly appreciated.