I am interested in cue making and I understand most of the techniques involved are traditional methods that have been around for a long time. I realize there are many cuemakers using CNC machines to cut patterns, I am curious if anyone uses 3D modelling to visualize new designs? Of particular interest to me is developing models and techniques for new methods of cue construction (joints, splicing, etc). I have an engineering background and it seems like there could be quite a bit of innovation available for new technologies in the cuemaking industry.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Modelling

- Thread starter metal5d

- Start date

Just wanted to say that I have done that in the past for others and I do it myself from time to time to visualize cue's or just when i'm bored.

I could put together a package but I can't imagine it selling very well as the time involved would certainly be a lot more than the return....

but anyway if you or anyone wants a cue modeled from 2d maps, just send them over and I'll put something together

I could put together a package but I can't imagine it selling very well as the time involved would certainly be a lot more than the return....

but anyway if you or anyone wants a cue modeled from 2d maps, just send them over and I'll put something together

Actually I was putting it out there that I am able to do 3D design work. I use Solidworks software. I am considering trying to come up with some models of the various joints and pins. I am starting to create a model of a 6 point cue I have now and using each individual part to create an assembly and exploded views. Almost all new parts designed in high technology companies are created in 3D and then 2D drawings are created from those parts.

For example:

For example:

3D Designs

One option to full scale 3D design might be to draw a butt of a cue as a rectangle in 2-D CAD and a Forearm as a retangle in 2-D CAD. Next draw points, inlays, veneers, etc. the same as real size.

Next, import the 2-D drawing to a 3-D CAD program such as Solidworks or Inventor and extrude into same thickness 3D block. Cut out Inlay holes completely through both sides of blocks and insert same size inlays flush with surface. Next, change materials of each of these to better reflect the look of the materials to be used. This could give a quick and easy way to compare different materials for different parts by switching back and forth easily. I am going to try this on a design, but am still working out the 2-D versions. Would be fairly quick, if you knew exactly what you wanted to draw from start.

One option to full scale 3D design might be to draw a butt of a cue as a rectangle in 2-D CAD and a Forearm as a retangle in 2-D CAD. Next draw points, inlays, veneers, etc. the same as real size.

Next, import the 2-D drawing to a 3-D CAD program such as Solidworks or Inventor and extrude into same thickness 3D block. Cut out Inlay holes completely through both sides of blocks and insert same size inlays flush with surface. Next, change materials of each of these to better reflect the look of the materials to be used. This could give a quick and easy way to compare different materials for different parts by switching back and forth easily. I am going to try this on a design, but am still working out the 2-D versions. Would be fairly quick, if you knew exactly what you wanted to draw from start.

I use Pro/E at work and will eventually get around to modeling a cue using different construction techniques. Solid modeling in Pro/E or Solidworks is very different from a simple line drawing. The parts actually have mass and density. Therefore, you can use it to calculate the balance point of a cue, and its overall weight. So if you had your standard cue model and wanted to see how the weight and balance would change by changing the point wood material, you could easily do that.

You could also see internal cross sections of the cue at any location to see for instance how thick the walls are around a threaded area.

There are many possibilities. The major drawback is the price. There are a few solid modeling engineering packages out there, and they all start at around $5,000 and can easily get up to the $20,000 range for one seat depending on the options you get with them. It can also take quite a long time to learn how to use them, but modeling cues would be on the easier side, as the shapes are all "squarish" and not "organic".

You could also see internal cross sections of the cue at any location to see for instance how thick the walls are around a threaded area.

There are many possibilities. The major drawback is the price. There are a few solid modeling engineering packages out there, and they all start at around $5,000 and can easily get up to the $20,000 range for one seat depending on the options you get with them. It can also take quite a long time to learn how to use them, but modeling cues would be on the easier side, as the shapes are all "squarish" and not "organic".

3D Modeling

I agree there is a big jump between seeing a simple flat model with realistic material looks and the full 3D modeling.

I agree there is a big jump between seeing a simple flat model with realistic material looks and the full 3D modeling.

I think you could sell a program if the cuemaker/customer could pick out his individual parts and build the 3-D cue. Sort of a "cut/past" type application. You could have a section for butt sleeves, forearms (plane, 4pt, 6pt, 8pt, 12pt, w/ or w/o veneers), different inlay shapes, in addition to the typical color pallet you could add a wood pallet (have all the different wood colors/grain available), different joint pins, collars, butt caps, etc. The cuemaker/customer can make all his/her selections and location in the cue where they go, then a 3-D picture of their creation would pop up. They could have the option to "drag/drop" the parts to get a variation of their design.

I'd buy this program if it were on the market (for the right price)!

Zim

I'd buy this program if it were on the market (for the right price)!

Zim

actually that could be done pretty cheaply, though again probably not worth the time to do it.

Setting up 4-5 basic cue lengths/tapers would be easy enough, and setting a specific material to each part and then an easy interface to choose types for those materials would also be easy...

How user friendly do you want it and how much are you willing to pay?

Anyway, I'm still doing it fro free to any that want or at a small rate for commericial ones, but if you read my other threads I've offered a free 3d program and a modeled cue to anyone that wants...

I also have extensive wood textures to apply... could all be done for free with a little bit of time spent learning the modeler....

Setting up 4-5 basic cue lengths/tapers would be easy enough, and setting a specific material to each part and then an easy interface to choose types for those materials would also be easy...

How user friendly do you want it and how much are you willing to pay?

Anyway, I'm still doing it fro free to any that want or at a small rate for commericial ones, but if you read my other threads I've offered a free 3d program and a modeled cue to anyone that wants...

I also have extensive wood textures to apply... could all be done for free with a little bit of time spent learning the modeler....

Within the next week or so. I will post some pictures of a cue that I have created in Solidworks. I could easily adapt it to change the inlay style / material, point size, # of veneers, colors and wood textures. If there were enough demand I could put together a stand alone program for cuemakers to piece together their designs. Anyone who would be interested please post or PM me with what you would want to see and what you think would be a fair price. It could even be adapted for CNC machines or to create production drawings.

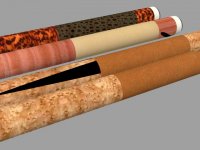

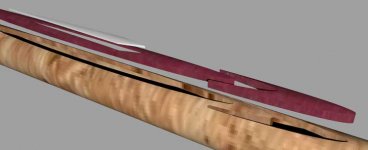

Rhino 3D Models

Here are a couple of 3-d models I have drawn with Rhino. I need to get a better image of the woods so they wrap better and don't blur. Either that or draw my cues parts smaller. But it can do a decent job so you can get an idea of what you are thinking about.

Here are a couple of 3-d models I have drawn with Rhino. I need to get a better image of the woods so they wrap better and don't blur. Either that or draw my cues parts smaller. But it can do a decent job so you can get an idea of what you are thinking about.