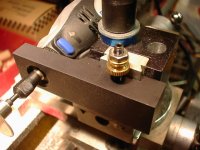

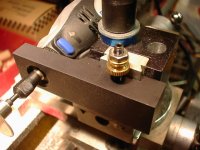

I found an adaptor for my toolpost, which is the smaller type, to hold my dremel tool with a carbide cutting blade. It was on Ebay, It has 3/4" x 12 tpi, or the same seller also has the other size 3/4" x 16tpi.

http://cgi.ebay.com/ws/eBayISAPI.dl...Sell_LogicX&refwidgettype=cross_promot_widget

I included some pics to show off my setup. I also got the blades on Ebay also. I found that it cuts better with the teeth facing down and the lathe spinning normal direction, no burn marks and the dremel bearly changed pitch. Enjoy.

Dave

http://cgi.ebay.com/ws/eBayISAPI.dl...Sell_LogicX&refwidgettype=cross_promot_widget

I included some pics to show off my setup. I also got the blades on Ebay also. I found that it cuts better with the teeth facing down and the lathe spinning normal direction, no burn marks and the dremel bearly changed pitch. Enjoy.

Dave