You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Ball screw

- Thread starter Michael Webb

- Start date

How long has this been out? I've got two cues that I've used the same OB shaft on and the original cue which is about six years old; the shaft is tight. On the newer cue which is about two years old, it's very loose. So much so, that unless I really tighten it to the extreme it will loosen. I haven't measured them; I guess I shouldDon't shoot the messenger but don't be surprised either.

This screw is not a Predator product.How long has this been out? I've got two cues that I've used the same OB shaft on and the original cue which is about six years old; the shaft is tight. On the newer cue which is about two years old, it's very loose. So much so, that unless I really tighten it to the extreme it will loosen. I haven't measured them; I guess I should

This screw is not a Predator product.

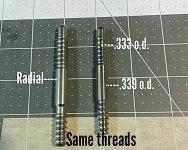

Was the screw advertised as radial or radial compatible? Atlas is the only source of radial pins I've found that come in consistent dimensions (and even then there is sometimes a few thou difference in OD).

To my knowledge it is Custom and not advertised as anything other than Proprietary.Was the screw advertised as radial or radial compatible? Atlas is the only source of radial pins I've found that come in consistent dimensions (and even then there is sometimes a few thou difference in OD).

The only reason I have one now, is the Gentleman plays with an after market c/f shaft. The fit was obviously to loose for his liking, so I changed it to a radial.

I figured show the Forum. I know how much everyone likes change here. Lol

Last edited:

Ball screws are originally designed for precision movement control, primarily in machine tools, and not for strength when being torqued down, so while I like the look, I don't care much for them in pool cues.

It's a can of worms at best. Like any other screw.Ball screws are originally designed for precision movement control, primarily in machine tools, and not for strength when being torqued down, so while I like the look, I don't care much for them in pool cues.

Joint screws in general.

After the choice of Individualism, and the proper tooling.

They are all a can of worms.

It was always the rule.

Don't take the job if you don't have the tools.

Then came someone like me who said to myself,

SELF??

You have the sources, get the taps made, and I did.

First run, proper taps for the 3/8x10.

Exspensive one of runs. I paid, got the split dies too so I could make joint protectors at Tournaments.

Then.........

Came the Radial joint screw and connection screw for the -A- joints.

Laughs on me. Can't get those taps made or dies either.

So....Congrats to uni loc. They created a system, offered the proper taps and short screws for joint protectors. They covered thier bases.

I respect that.

After the choice of Individualism, and the proper tooling.

They are all a can of worms.

It was always the rule.

Don't take the job if you don't have the tools.

Then came someone like me who said to myself,

SELF??

You have the sources, get the taps made, and I did.

First run, proper taps for the 3/8x10.

Exspensive one of runs. I paid, got the split dies too so I could make joint protectors at Tournaments.

Then.........

Came the Radial joint screw and connection screw for the -A- joints.

Laughs on me. Can't get those taps made or dies either.

So....Congrats to uni loc. They created a system, offered the proper taps and short screws for joint protectors. They covered thier bases.

I respect that.

I think that it relies on the compression fit on the ID of the generated form and Not the OD of the pin. I can't see it working any other way. The area at the crest of the form is insufficient to last any length of time. Being old fashioned, I like the 18tpi pins myself. You get it staying together tighter for the same radial torque. One thing I used to notice was how often players were subconsciously tightening or effectively checking if the cue was still tight at the joint. Even seen snooker players do that too.

Thanks for the thread and showing the different but effectively the same looking pin.

Apart from the od difference, did you try to see what the pins minor diameter is?

I used to have a pair of Ø1/8 rollers that had a flat on them for measuring big threads on the flank angle. The flats are for the mic anvils to sit on and it is a comparative measurement. I need to make more if people out here have some issues.

Thanks for the thread and showing the different but effectively the same looking pin.

Apart from the od difference, did you try to see what the pins minor diameter is?

I used to have a pair of Ø1/8 rollers that had a flat on them for measuring big threads on the flank angle. The flats are for the mic anvils to sit on and it is a comparative measurement. I need to make more if people out here have some issues.

DeeDeeCues

Well-known member

I think that it relies on the compression fit on the ID of the generated form and Not the OD of the pin. I can't see it working any other way. The area at the crest of the form is insufficient to last any length of time. Being old fashioned, I like the 18tpi pins myself. You get it staying together tighter for the same radial torque. One thing I used to notice was how often players were subconsciously tightening or effectively checking if the cue was still tight at the joint. Even seen snooker players do that too.

Thanks for the thread and showing the different but effectively the same looking pin.

Apart from the od difference, did you try to see what the pins minor diameter is?

I used to have a pair of Ø1/8 rollers that had a flat on them for measuring big threads on the flank angle. The flats are for the mic anvils to sit on and it is a comparative measurement. I need to make more if people out here have some issues.

One small point, as for it staying together tighter with the same torque, that is half true. The two joints will be just as tight if the diameters are the same. The fine thread will be less susceptible to loosening due to vibration.

Everything is smaller in it. They scaled it down on purpose so if you wanted an extra shaft that fit correctly. You had to go to them.I think that it relies on the compression fit on the ID of the generated form and Not the OD of the pin. I can't see it working any other way. The area at the crest of the form is insufficient to last any length of time. Being old fashioned, I like the 18tpi pins myself. You get it staying together tighter for the same radial torque. One thing I used to notice was how often players were subconsciously tightening or effectively checking if the cue was still tight at the joint. Even seen snooker players do that too.

Thanks for the thread and showing the different but effectively the same looking pin.

Apart from the od difference, did you try to see what the pins minor diameter is?

I used to have a pair of Ø1/8 rollers that had a flat on them for measuring big threads on the flank angle. The flats are for the mic anvils to sit on and it is a comparative measurement. I need to make more if people out here have some issues.

I have a radial joint screw in my Cue, its real old now. Never once, has it loosened on me.

Joint screws plus proper hole size and threads

And....

Proper facings on the joints.

Pretty simple stuff!

My 3/8x10's fit very well too but I invested in the proper taps to match the minor on the screw.

I have to many bloody taps across the board.

Last edited:

The thing about ball screws and taps and dies for them is that they were never meant to be used in an application where a tapped hole and a threaded rod mated. They were designed to be driven, or to drive balls.

DeeDeeCues

Well-known member

The thing about ball screws and taps and dies for them is that they were never meant to be used in an application where a tapped hole and a threaded rod mated. They were designed to be driven, or to drive balls.

But, but, but, they look different so they must be better. And they cost so much, they must be better. Nobody would charge so much for an inferior product!

LmaoBut, but, but, they look different so they must be better. And they cost so much, they must be better. Nobody would charge so much for an inferior product!

I like that answer.

It's the same old story.The thing about ball screws and taps and dies for them is that they were never meant to be used in an application where a tapped hole and a threaded rod mated. They were designed to be driven, or to drive balls.

But

There sure is a lot of Cue makers offering it.

You know the deal.

Opinions vary. Can't change that if you tried.

few people realize thatBall screws are originally designed for precision movement control, primarily in machine tools, and not for strength when being torqued down, so while I like the look, I don't care much for them in pool cues.

Kim