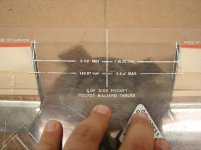

I have an antique table that was given to me quite a few years ago, I think it's a Brunswick Wellington that had the emblem replaced by a local mechanic back in the day. It's obvious that the emblem was changed, it now says W.A. Bergen St Paul Minn, anyway, the table is in pretty good shape and most any work needed I can do myself. Except the rails! I have read through Bigkahuna's thread and his rails sound like the ones I have. I don't have the knowledge or equipment to repair the rails. The pocket openings are really big! 5.5 inch on the corners and 6 on the sides. I would like to tighten up the pockets and still have the table preform correctly. Does anyone have a suggestion of who or what company I could have do this rail work?

Below is a picture of the table, if anyone knows who the manufacturer is, please let me know.

Thanks in advance!

Twice

Below is a picture of the table, if anyone knows who the manufacturer is, please let me know.

Thanks in advance!

Twice