Hmm, that one's priveledge info too.((VH)) said:well if Bandido would oblige it's up to him.

Btw Joseph, meeting up with Blud?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bandido's cues

- Thread starter bandido

- Start date

You're right that it's proprietary. But the detachable pin in the forearm tenon is just one component of a multi-part accu-center system that I developed. So just barely seeing it doesn't really give away the secret.Joseph Cues said:Hmm, that one's proprietary I think.

If you noticed, I also intentionally did this veneered forearm using medium colored, medium-high density forearm stock and light colored veneers. This is because of it being a "check piece" or "experimental subject". I was also checking for the presence of "dark staining characteristic" of the adhesive that I used, calculated feed rate of the cutter and veneer jig's accuracy. There's no sense cheating myself in this experiment by using ebony forearm and black stained adhesive as seen in some veneered v-spliced cues.

Last edited:

Here it is.Joseph Cues said:Hooowowwwwww!!!!!!!!!!

Ed, a closeup of the top of the points where the veneers end would be nice.

Thanks Joey.Joseph Cues said:I'm emailing this to my friend to see if he wants to get the first ones you make.

Just barely, but do notice the bottom part of the accu-center stud. You will see the locking slot for the rest of the mandrel's components. That center hole was used for manufacturing the mandrel and has nothing to do with working on the cue.Joseph Cues said:You're showing some secrets here Ed. Might wanna edit the pics a little.

Attachments

Sorry, a close-up of the stud of the detachable centering mandrel is out of the question. I have been making some joint mandrels for Joseph and somehow got the urge and idea on how to make an accu-center mandrel for the A-joint end for v-splicing. Needless to say, it turned out working perfectly with the other v-splicing machinery that I've been working on.((VH)) said:Nice pics! Any additional inlay work for the two?

How about a close-up shot of the rear where threads are?

((VH)) said:I see the pins are there, what joint do you have in mind there? Or is it just that?

That pin in the A-joint end will be detached as it's part of the Accu-center components. My A-joint has the threaded wooden tenon (as seen) in conjunction with a reverse threaded non-metallic G9 or carbon fiber stud which has better adhesion property and lower resonance frequency (closer to the wood's) than metal studs. Revrse threading it helps equalize the twisting forces that the cue is subjected to.

Last edited:

V

((VH))

Guest

bandido said:After 12 years, V-spliced points revisited. I just finished putting together equipment and a new system for myself on putting together v-spliced points. The centering mandrels are still shown protruding out of the forearm/handle tenon.

These are 5 pointers and the multi-veneered (bottom on top picture and left on the bottom picture) has two 0.9mm and two 0.23 mm veneers. These are the first two products of my new v-splicing system.

12 years seem to be a long wait

Using just flat bottom points or CNC?

Ed, nice veneers. I don't see the glue lines at all.

Last edited:

Hell, why bother patenting this?

WHO will be willing to do this much work for his A-joint?

I don't know how it can be made any tighter.

WHO will be willing to do this much work for his A-joint?

I don't know how it can be made any tighter.

Last edited:

For the Love of God Man!! I will let you know when I sell my car ER so i can buy one!

V

((VH))

Guest

That's a very tough joint I see, but lots of work.

That would be 5-6" of that composite bolt you got there, if am not mistaken.

The tenon seems to be bigger than the usual 5/8, not sure though. Am I right?

That would be 5-6" of that composite bolt you got there, if am not mistaken.

The tenon seems to be bigger than the usual 5/8, not sure though. Am I right?

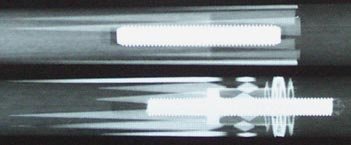

Here's an x-ray of how some others normally do their A-joint. They work too but the integrity of such relies a lot on the strength of the surrounding components. They don't use the 3/8"-10tpi as Joseph has mentioned though. One uses the 3/8"-16tpi while the other uses 5/16"-18tpi.((VH)) said:That's a very tough joint I see, but lots of work.

That would be 5-6" of that composite bolt you got there, if am not mistaken.

The tenon seems to be bigger than the usual 5/8, not sure though. Am I right?

Hey Joseph, it's better safe than sorry. One positive result from this QP fiasco is my learning to appreciate, at a higher degree, the time and effort that I put into the craft.

Attachments

I take tradesBuddha Jones said:For the Love of God Man!! I will let you know when I sell my car ER so i can buy one!

bandido said:After 12 years, V-spliced points revisited. I just finished putting together equipment and a new system for myself on putting together v-spliced points. The centering mandrels are still shown protruding out of the forearm/handle tenon.

These are 5 pointers and the multi-veneered (bottom on top picture and left on the bottom picture) has two 0.9mm and two 0.23 mm veneers. These are the first two products of my new v-splicing system.

What type of wood is used here bandido?

I used the base wood or the less figured part of the red amboyna burl.Poolschool said:What type of wood is used here bandido?

These two cues will almost surely develop buzzing later on imo.bandido said:Here's an x-ray of how some others normally do their A-joint. They work too but the integrity of such relies a lot on the strength of the surrounding components. They don't use the 3/8"-10tpi as Joseph has mentioned though. One uses the 3/8"-16tpi while the other uses 5/16"-18tpi.

Hey Joseph, it's better safe than sorry. One positive result from this QP fiasco is my learning to appreciate, at a higher degree, the time and effort that I put into the craft.

I know of only one cuemaker who uses a 5/16 18 pin in the A-joint.

Zyler has an x-ray of a cue of his too. He is a western state based high-end cuemaker.

Ed, I think you are one of the few cuemakers who are no longer using 3/8 metal stud in the A-joint.

Okay, I gotta ask this. I'm not a cuemaker, so I'm probably missing something simple here, but how do you assemble this with the tenon threads opposed to the pin threads?bandido said:My A-joint has the threaded wooden tenon (as seen) in conjunction with a reverse threaded non-metallic G9 or carbon fiber stud which has better adhesion property and lower resonance frequency (closer to the wood's) than metal studs. Revrse threading it helps equalize the twisting forces that the cue is subjected to.

-CM

No it's 3 1/2", the major dia. of the tenon is 19mm (3/4") and the minor dia. is 16 mm.((VH)) said:That's a very tough joint I see, but lots of work.

That would be 5-6" of that composite bolt you got there, if am not mistaken.

The tenon seems to be bigger than the usual 5/8, not sure though. Am I right?

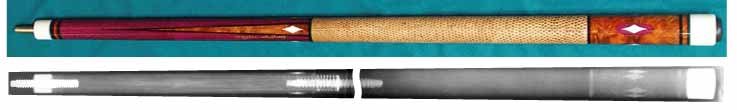

bandido said:Here's a picture and x-ray of an ERupt Series that I just shipped out. Flash and Dash.

Cool pic, Edvin !

bandido said:And this piece of information may just be the shocker. All the cavities for the inlays in all the cues that you've seen were cut with these tools.Told you that you'll be shocked, as even Sherm Adamson who recently visited my shop was.

Bandido, Sherm came to the Phils? He lives 20 minutes from me. I used to see Sherm all the time but he has been so busy making cues lately. He makes a nice cue. www.shermcue.com

Last edited: