robbycar

Registered

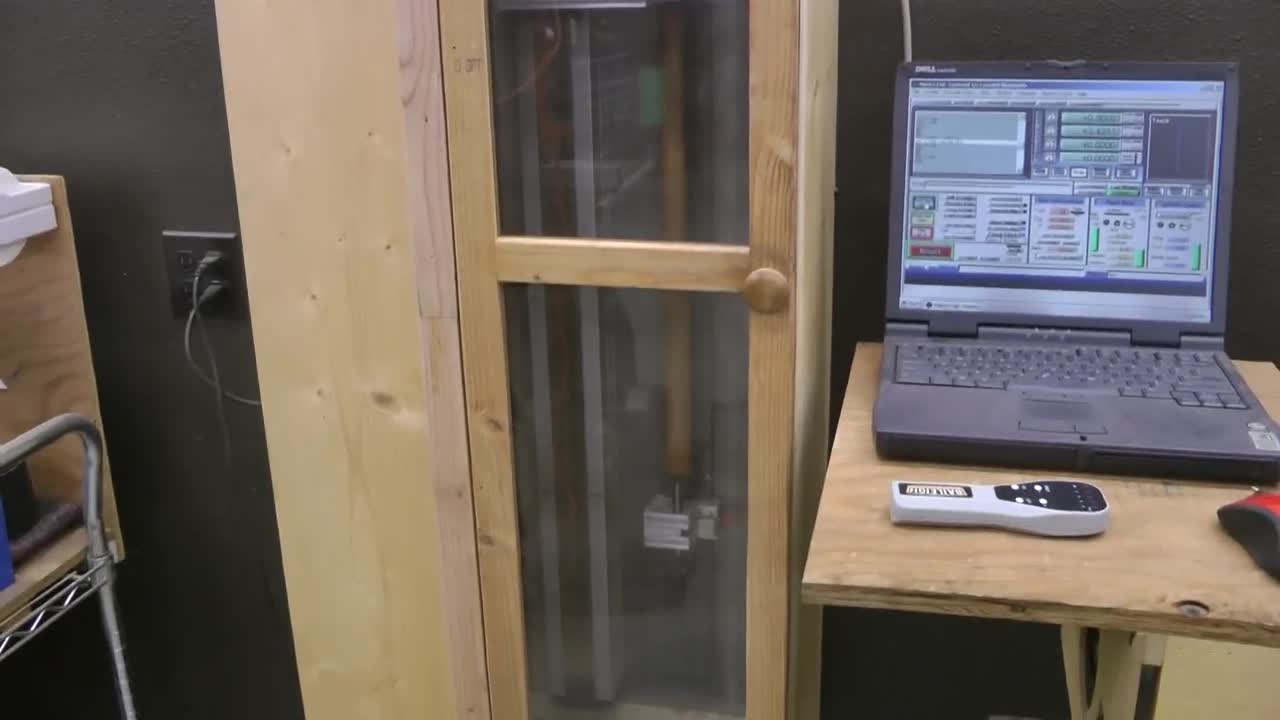

I have a 6090 router with 4th axis spindle, works great for tapering, but it sure makes a mess.

I tried some plastic curtains, and following with a vacuum cleaner, but neither worked very well.

Would someone be able to send me some pics of best practice to fix this?

Thanks in anticipation!

I tried some plastic curtains, and following with a vacuum cleaner, but neither worked very well.

Would someone be able to send me some pics of best practice to fix this?

Thanks in anticipation!