You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

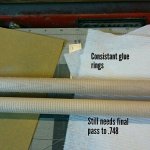

Coring dowels and glue rings

- Thread starter Michael Webb

- Start date

JC

Coos Cues

Don't work harder than you have to. Two days after I gun drill, I use a reamer which helps get the size dowell I want to use. .003 to .004 clearance. Perfect for glue.

Hope this helps.

View attachment 521004

View attachment 521005

View attachment 521006

Good stuff thanks!

What size ID decorative rings are you using at that Joint? Do you pre build the ring pack in a jig first so they don't fall into the tight spaced glue grooves? What type of glue are you using with the cores?

On a semi related note I'm interested in how or whether folks pre build ring packs up. I saw Bob Dz's video on youtube how he does it and it looks pretty good. I know some use the core itself as the jig and face the outer ring before attaching the parts. Maybe this should be a separate thread or has been discussed already I haven't found much in a search.

Thanks,

JC

Good stuff thanks!

What size ID decorative rings are you using at that Joint? Do you pre build the ring pack in a jig first so they don't fall into the tight spaced glue grooves? What type of glue are you using with the cores?

On a semi related note I'm interested in how or whether folks pre build ring packs up. I saw Bob Dz's video on youtube how he does it and it looks pretty good. I know some use the core itself as the jig and face the outer ring before attaching the parts. Maybe this should be a separate thread or has been discussed already I haven't found much in a search.

Thanks,

JC

Hi John

Two great parts about using a 7/8x9 split die as opposed to a 3/4" is, I have control over the dept of the grooves. It really doesn't take much to achieve the job. Secondly, it only takes about 5 seconds to thread the dowell whether it 15 inches for a forearm or 19 inches for a handle. I like the forearms 14 inches when cutting points so the cutter doesn't run out and I still have a cavity in the Vee groove for epoxy. It gets cut off later.

I left the glue for the core out on purpose to avoid the can of worms but with my tolerances, I can use whatever glue I choose.

Gorilla glue.... YOU DO NOT NEED WATER!

Wood has moisture, it is plenty to activate the glue.

Epoxy

I do not use 5 minute epoxy for anything. I don't like it or anything about it. That's my preference but I do not condemn those who like it. I don't judge.

I'm a West system 205, 206 and 207 guy. If I use it on cores, I mix 403 or 404 powder with it. It adds density to the epoxy which eliminates the possibility of a buzz if the wood has soft spots which can absorb the epoxy and leave a dry spot.

I don't do the ring packs. I build as I go one by one.

Hope this helps.

Last edited:

That's a clever way to do glue relief grooves if you dont have the machinery to cut threads :smile:

As long as the dowell is supported. Meaning, use your live center in the tail stock. It's very consistant. Don't use the tailstock and let the dowell whip. You won't be happy.

YUP.... I tried.

Hi Michael,

With your resin, do you split some off and not add any filler, using that as a primer resin on the dowel and a coat through the hole. Then while that is soaking in, mix the fibre fillers and reglue using the filled glue and assembly? I was adding milled glass to my resin as a reinforcing , bonding agent. Works very well, but it does require slightly more total clearance to assemble. Another thing was to create an area of excess resin to act as a reservoir so it could draw in resin if needed.

Instead of the split die like you use, I just use a thread chaser and does the same thing. Either way, consistency I feel is really important. It eliminates a lot of variables.

Then something else comes along and you make it totally different, lol

With your resin, do you split some off and not add any filler, using that as a primer resin on the dowel and a coat through the hole. Then while that is soaking in, mix the fibre fillers and reglue using the filled glue and assembly? I was adding milled glass to my resin as a reinforcing , bonding agent. Works very well, but it does require slightly more total clearance to assemble. Another thing was to create an area of excess resin to act as a reservoir so it could draw in resin if needed.

Instead of the split die like you use, I just use a thread chaser and does the same thing. Either way, consistency I feel is really important. It eliminates a lot of variables.

Then something else comes along and you make it totally different, lol

Hi Michael,

With your resin, do you split some off and not add any filler, using that as a primer resin on the dowel and a coat through the hole. Then while that is soaking in, mix the fibre fillers and reglue using the filled glue and assembly? I was adding milled glass to my resin as a reinforcing , bonding agent. Works very well, but it does require slightly more total clearance to assemble. Another thing was to create an area of excess resin to act as a reservoir so it could draw in resin if needed.

Instead of the split die like you use, I just use a thread chaser and does the same thing. Either way, consistency I feel is really important. It eliminates a lot of variables.

Then something else comes along and you make it totally different, lol

Hi Neil

I mix it complete with the filler and coat both pieces well before assembly. Delrin makes for a good plunger.

Last edited:

Conclusion:

Today I'm doing the final turn on the cores. With the new reamer, the hole is at .756. I succeeded in dry fitting at .751 1/2.

That's not bad. 40 pieces cored.

Please, don't take my word for it. Try it.

Today I'm doing the final turn on the cores. With the new reamer, the hole is at .756. I succeeded in dry fitting at .751 1/2.

That's not bad. 40 pieces cored.

Please, don't take my word for it. Try it.

Last edited: