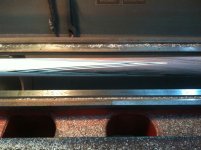

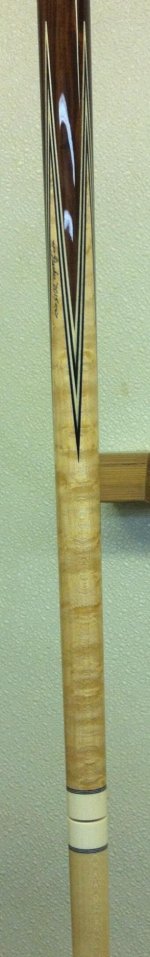

I am having a custom full-spliced cue made for me from the folks at Prather in Mooreland, OK. Very nice people! This will be modeled after their 1915 series, a classic four-point four-veneered cue which has a nice old school look and feel to it:

I've heard nothing but great things about the blanks from Prather, so I jumped on an opportunity to have one made out of Rosewood and birdseye with black/white/black/white veneers and trim rings.

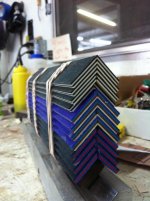

The best part of this transaction so far has been that Jeff has been sending me "live update" text messages with pics of the progress of the build! How cool is that? I thought it would be worthwhile to create a thread and share the pics with people, as I have found it to be pretty fascinating.

Here are the four pics I have thus far, will be adding to this post as the work continues. Thanks again to Jeff and all the folks at Prather, keep up the great work!

I've heard nothing but great things about the blanks from Prather, so I jumped on an opportunity to have one made out of Rosewood and birdseye with black/white/black/white veneers and trim rings.

The best part of this transaction so far has been that Jeff has been sending me "live update" text messages with pics of the progress of the build! How cool is that? I thought it would be worthwhile to create a thread and share the pics with people, as I have found it to be pretty fascinating.

Here are the four pics I have thus far, will be adding to this post as the work continues. Thanks again to Jeff and all the folks at Prather, keep up the great work!

Attachments

Last edited: