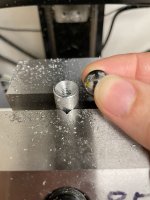

Thanks. No, the white base is 3D printed. I drew it up last night to be able to bolt it to the indicator stand that was delivered and try a few balls. I was excited to try it. It works surprisingly well. I can repeat to about .0002". It deforms I press hard into it, but if I'm gentle when I spin the ball, it works really well. The real one would be metal, either aluminum or steel, and have steel ball bearings epoxied into it.

It's interesting the printed base works so well. I would have assumed the ridges between layers would have produced significant error (let alone the lack of concentricity on the printed dome).