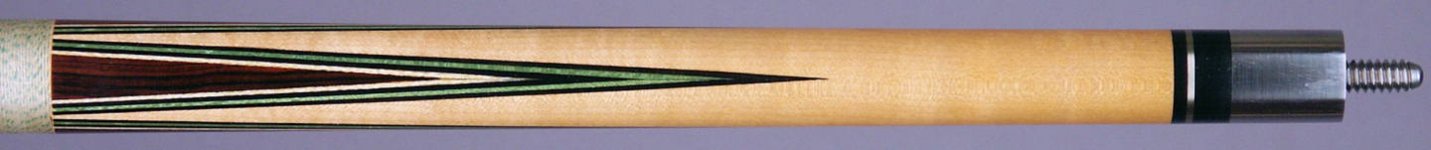

Sharp points via half or full splice. Inlay-ed points are a no go for me. I'd rather play with an ebony merry widow w/ a leather wrap than a cue with rounded points.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do you like Sharp points

- Thread starter one stroke

- Start date

Your "reaction" is wrong.... Cues with rounded tops are due to the the point inlays being cut that way and inlaid (not) spliced or "v" cut. The round tip is due to the radius of the cutter used. Just about every inlay you see in every cue is cut with the same cutters and so are the pockets for those inlays. Those pockets ALL have radiuses. It's whether the maker decides to relieve them by "cutting in" the corners or not. MOST makers ( yes including Jerry ) don't bother and just run the cutter up a bit to accommodate the sharp corners of the inlay and fill the tiny exposed radiuses with epoxy. This is common place in many traditional builders. Some cut in the corners. For example, Tony from Black Boar inlays his points as well. They are not spliced. The flat bottom pockets start out with radiuses at the tips which are then cut in to accommodate the sharp tip inlay...Searing is one of them that cuts in his corners when need be but on inlays only. His points are traditionally spliced but with his own technique...

As for your theory, I don't think TAD, Ginacue, nor Josswest would agree with your "in a hurry" "rushed" thoughts since their prongs are also inlaid not spliced with the outer point tips rounded and they don't/didn't "forget" anything.... Their cues look AMAZING.

What you like is what you like that's all well and good. Just thought you could use a little more info on the subject...

I think you have no idea what you're talking about

I think you have no idea what you're talking about

You're pragably right... My 25+ years experience in the cue building industry and writing CNC machine code has been for nothing...

You're so funny Jason... Now go play in your sand box...

Adam.vickers

Registered

You're pragably right... My 25+ years experience in the cue building industry and writing CNC machine code has been for nothing...

You're so funny Jason... Now go play in your sand box...

So that makes you a expert on what customer perception of rounded points ,,

Rounded points suggest production cue quality , anything on the end of the points suggest a cover up of bad point work

Epoxy surrounding points or inlays suggest amature cue building or a builder with lessor equipment that is not capable of exact cutting

If these are what we see wonder what we would find where we can't see

Sharp points +100... and dead even, please. Gus, Gina, Tad, Tasc... some of the best.

And veneers, 4 or 5... why build a custom cue with no veneers on the points?

Don't care for floating points at all. I also am not a fan of diamonds, dots, or spears on the tips of points... don't like the look, and I think it's a saver for uneven points.

There was a really nice Richard Black on the 'Bay, but the spears on the points killed it for me.

"Box" cues?.. meh.

Some cues have a very slightly rounded point, Schon and Pechauer come to mind... depends on the cue..

some of the earlier Schons have a slightly rounded point, but the design looks nice... one of my pool buds has an early Schon,

a few diamond inlays with the small rounded point, looks nice.

Turquoise, gems, any sparkly fillers are a non-starter... I passed on a Scruggs that came up because it had turquoise in the points/boxes... meh.

And veneers, 4 or 5... why build a custom cue with no veneers on the points?

Don't care for floating points at all. I also am not a fan of diamonds, dots, or spears on the tips of points... don't like the look, and I think it's a saver for uneven points.

There was a really nice Richard Black on the 'Bay, but the spears on the points killed it for me.

"Box" cues?.. meh.

Some cues have a very slightly rounded point, Schon and Pechauer come to mind... depends on the cue..

some of the earlier Schons have a slightly rounded point, but the design looks nice... one of my pool buds has an early Schon,

a few diamond inlays with the small rounded point, looks nice.

Turquoise, gems, any sparkly fillers are a non-starter... I passed on a Scruggs that came up because it had turquoise in the points/boxes... meh.

Last edited:

So that makes you a expert on what customer perception of rounded points ,,

Rounded points suggest production cue quality , anything on the end of the points suggest a cover up of bad point work

Epoxy surrounding points or inlays suggest amature cue building or a builder with lessor equipment that is not capable of exact cutting

If these are what we see wonder what we would find where we can't see

You can have perception but it didn't make it correct. Opinion is different. If you like sharp points or rounded that is all good but if you say rounded anything suggests inferior work you are dead wrong.. There are very few cue makers who don't have epoxy fill at the tips and corners of their non "sharp" inlays. THAT is a fact. Most of the time if you see a cue with an ebony sleeve, there is filler. Like I said SOME makers cut in their corners and go the extra mile. But the list is relatively short.... Name the cue makers you know that inlay everything sharp and ALL corners are cut in to leave no filler..

Sorry for the rookie question, but

Why does my $17, one piece cue from Seyberts that I use as my mechanical bridge handle, have points that taper to a pin point, while my $500 Schon has rounded CNC points?

It must be something in the manufacturing process, but PLEASE let me know. This has bugged me for years. :shrug:

BTW, to me, points are totally irrelevant. I'm noticing more and more pros are also using really plain Jane cues.

Thank you for the answer!!! :smile:

Why does my $17, one piece cue from Seyberts that I use as my mechanical bridge handle, have points that taper to a pin point, while my $500 Schon has rounded CNC points?

It must be something in the manufacturing process, but PLEASE let me know. This has bugged me for years. :shrug:

BTW, to me, points are totally irrelevant. I'm noticing more and more pros are also using really plain Jane cues.

Thank you for the answer!!! :smile:

If it has sharp points and resembles a Titlist. The cheaper the cue is the less important of an issue it is for me.

For those who think it does not matter not only can I draw better but I can follow like nobodies business too.

For those who think it does not matter not only can I draw better but I can follow like nobodies business too.

Sharp points +100... and dead even, please. Gus, Gina, Tad, Tasc... some of the best.

And veneers, 4 or 5... why build a custom cue with no veneers on the points?

Don't care for floating points at all. I also am not a fan of diamonds, dots, or spears on the tips of points... don't like the look, and I think it's a saver for uneven points.

There was a really nice Richard Black on the 'Bay, but the spears on the points killed it for me.

"Box" cues?.. meh.

Some cues have a very slightly rounded point, Schon and Pechauer come to mind... depends on the cue..

some of the earlier Schons have a slightly rounded point, but the design looks nice... one of my pool buds has an early Schon,

a few diamond inlays with the small rounded point, looks nice.

Gina and Tad inlay their points and the outer tips are rounded UNLES they used someone else's blank like Brunswick and the like. As for Schon their points have a big radius at the tips and it looks unbalanced to me. If those radiuses we let's say .020, the point would look much better... Their rounded diamonds are no better imo.... As for not building a custom cue with no veneers or as some have mentioned putting something at the tips is "covering" up something, how about these with no veneers and inlays at the tips.. What was the motivation of this maker below?..Not too shabby eh'...

Sorry for the rookie question, but

Why does my $17, one piece cue from Seyberts that I use as my mechanical bridge handle, have points that taper to a pin point, while my $500 Schon has rounded CNC points?

It must be something in the manufacturing process, but PLEASE let me know. This has bugged me for years. :shrug:

BTW, to me, points are totally irrelevant. I'm noticing more and more pros are also using really plain Jane cues.

Thank you for the answer!!! :smile:

Most sneaky's are full spliced which means the points can "disintegrate" to a sharp point. The ones that are rounded are inlaid flat bottom and put in like puzzle pieces... For rounded tips the size of the radius at the tip is usually the size of the cutter they used to cut out the puzzle "pocket".

You can have perception but it didn't make it correct. Opinion is different. If you like sharp points or rounded that is all good but if you say rounded anything suggests inferior work you are dead wrong.. There are very few cue makers who don't have epoxy fill at the tips and corners of their non "sharp" inlays. THAT is a fact. Most of the time if you see a cue with an ebony sleeve, there is filler. Like I said SOME makers cut in their corners and go the extra mile. But the list is relatively short.... Name the cue makers you know that inlay everything sharp and ALL corners are cut in to leave no filler..

That's the point ,, I like cues on the short list ,,

1

Most sneaky's are full spliced which means the points can "disintegrate" to a sharp point. The ones that are rounded are inlaid flat bottom and put in like puzzle pieces... For rounded tips the size of the radius at the tip is usually the size of the cutter they used to cut out the puzzle "pocket".

Thank you, Skins! I realize you're correct, but that, however, sounds counter intuitive. Doesn't a full splice mean joining two sections of material, and hence, a lot more labor? How can they sell 'em for under $20, and still manage to make a profit?

I had always thought that a full splice was highly desirable, but apparently my Schon is not a full splice? Thanks to you for taking the time to respond to my question without making me feel like a fool! Much appreciated. Not even any snide sarcasm either. :thumbup::thumbup2:

Gina and Tad inlay their points and the outer tips are rounded UNLES they used someone else's blank like Brunswick and the like. As for Schon their points have a big radius at the tips and it looks unbalanced to me. If those radiuses we let's say .020, the point would look much better... Their rounded diamonds are no better imo.... As for not building a custom cue with no veneers or as some have mentioned putting something at the tips is "covering" up something, how about these with no veneers and inlays at the tips.. What was the motivation of this maker below?..Not too shabby eh'...

Yeah, not shabby at all!

But Tad's points are spliced, not inlaid... and these ain't rounded...

Tad

Early Gus

My Gus

Attachments

Last edited:

That's the point ,, I like cues on the short list ,,

1

The point was you probably can't name many because you don't think you know who does what...

Like I said, like what you like. Just don't dislike for the wrong reasons..

Gina and Tad inlay their points and the outer tips are rounded UNLES they used someone else's blank like Brunswick and the like. As for Schon their points have a big radius at the tips and it looks unbalanced to me. If those radiuses we let's say .020, the point would look much better... Their rounded diamonds are no better imo.... As for not building a custom cue with no veneers or as some have mentioned putting something at the tips is "covering" up something, how about these with no veneers and inlays at the tips.. What was the motivation of this maker below?..Not too shabby eh'...

Yeah, not shabby at all!

But Tad's points are spliced, not inlaid... and these ain't rounded...

Tad

Early Gus

My Gus

The first and second picture are early Tad examples.. Yes early on Tad Kohara did fill splice some of his fronts.. Hasn't done that for a long time...

Last edited: