I have someone else do mine. I also have someone else cut my hair and another someone else do any dental work I need!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do you retip your cue or have it done by someone?

- Thread starter nevadarain

- Start date

I can think of only two people that I would trust to touch my ivory ferules.

I do all of my tips by hand. No lathe, just a razor knife blade.

I use a 14 mm tip on a 13 mm shaft. and work it down by standing the shaft on the tip and carve it down. working away from the ferule.

I just came across this video on youtube. It is very similar to my method.

Changing a Tip - When and how

I never did well trying to do my own. It can be a problem finding someone who you trust to do a good job, though. When we moved to South Carolina I took my Dishaw to a local billiard supply store. Never again. Had a couple of different people do it but Mike Gulyassy does mine now. May cost more but it gets done right!

The fact that you admit you can't do a tip by hand doesn't mean you have any knowledge on those of us who can, and have been doing it for decades.

By the way, my Browne & Sharpe assures me that my tip is perfectly round after I finish, to the thousandth of an inch, if that's close enough for you. If Browne & Sharpe isn't familiar, it's a micrometer. I wouldn't be without it.

All the best,

WW

I never said I can't do a tip by hand....so read again....but why would I when I have a cue repair lathe and actually care enough to properly service my cues and the cues of others on a daily basis??? ...And as for your amazing micrometer...it does not measure runout...you would need a dial indicator and a lathe to do that...as I said I will guarantee your tips are not even close to round.

I never said I can't do a tip by hand....so read again....but why would I when I have a cue repair lathe and actually care enough to properly service my cues and the cues of others on a daily basis??? ...And as for your amazing micrometer...it does not measure runout...you would need a dial indicator and a lathe to do that...as I said I will guarantee your tips are not even close to round.

As usual, you have no substantive contribution to this thread. You never do. Also, refer to my pictures and tell me where they look off to you. I have more examples. You, on the other hand, do not put up any evidence.

I get the tips, to the thousandth of an inch, to the same diameter as the ferrule, to the whole thickness of the tip. After a little mushrooming, the same procedure, as the tip stabilizes. And it's by hand, as I described it above, which you seem to have a problem with.

I don't know why you have such a hard time on those of us who do this by hand. But, then again, you are obviously an ideologist. No big challenge to tell who is who.

All the best,

WW

I have done both in the past. Now days I take it to the feller that made the cue and have him put on another. His shop is very close, so I don't bother with it anymore.

As usual, you have no substantive contribution to this thread. You never do. Also, refer to my pictures and tell me where they look off to you. I have more examples. You, on the other hand, do not put up any evidence.

I get the tips, to the thousandth of an inch, to the same diameter as the ferrule, to the whole thickness of the tip. After a little mushrooming, the same procedure, as the tip stabilizes. And it's by hand, as I described it above, which you seem to have a problem with.

I don't know why you have such a hard time on those of us who do this by hand. But, then again, you are obviously an ideologist. No big challenge to tell who is who.

All the best,

WW

Here's some evidence for you bro......

Also.....you can ask Mika Immonen Thiorsten Hohmann Hunter Lombardo, Jen Baretta,, Emily Duddy and just about anybody in New York City that plays pool that I Do tip work for in a regular basis how my work holds up....but here's a few pics....PS. Why don't you post some Macro shots for a real critique.

Evidence A

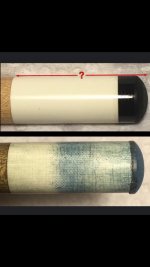

The red line was added to show how the ferrule doesn't Bell after a proper cleaning and polishing......this is a before and after obviously

Attachments

Last edited:

Why don't you post some Macro shots for a real critique.

Fair point, but I don't have a camera with that type of setting. I think my pictures show a pretty good amount of detail. Here's another one. This one's Elk Master, so it doesn't burnish quite as high on the sides as some others. Bear in mind, none of these are brand new, all have some use on them.

Your work looks fine, as long as you're not sanding those ferrules, other than to get rid of a bell. One of the most common mistakes I see over time.

Now try something unusual - Give a bit of credit to the do it yourself types out there. Some are better than you think. :thumbup:

All the best,

WW

Attachments

Fair point, but I don't have a camera with that type of setting. I think my pictures show a pretty good amount of detail. Here's another one. This one's Elk Master, so it doesn't burnish quite as high on the sides as some others. Bear in mind, none of these are brand new, all have some use on them.

Your work looks fine, as long as you're not sanding those ferrules, other than to get rid of a bell. One of the most common mistakes I see over time.

Now try something unusual - Give a bit of credit to the do it yourself types out there. Some are better than you think. :thumbup:

All the best,

WW

It's not about giving credit....I can do a fine job by hand but won't because it's not the right way or safe way to do a quality repair.....Having a lathe and knowing how to operate it it still a DIY....and takes a lot more care then doing a tip by hand because there is NO room for error. I understand some people you included don't want to invest in a lathe and that's your choice. But to offer advice and tell someone to potentially damage there cue by doing Hand repairs is insulting and not right. I am a professional at doing basic cue repairs as are many many members here that have made the investment in learning how to use the proper tools to do the job correctly.

I used to do them myself with the Willard machine but now I have the cumaker or 2 of my buddies with lathes do it.

As usual, you have no substantive contribution to this thread. You never do. Also, refer to my pictures and tell me where they look off to you. I have more examples. You, on the other hand, do not put up any evidence.

I get the tips, to the thousandth of an inch, to the same diameter as the ferrule, to the whole thickness of the tip. After a little mushrooming, the same procedure, as the tip stabilizes. And it's by hand, as I described it above, which you seem to have a problem with.

I don't know why you have such a hard time on those of us who do this by hand. But, then again, you are obviously an ideologist. No big challenge to tell who is who.

All the best,

WW

Those look really great. You should totally write a guide. Would love to read something like that. What's wrapped around the ferrule? Just tape?

Those look really great. You should totally write a guide. Would love to read something like that. What's wrapped around the ferrule? Just tape?

Thank you very much. I gave what I do on page 2, but this is a pretty popular thread, so repeated here. Again, thanks.

"Certainly, and thanks for the compliment. After gluing on the tip, I putting Scotch freezer tape around the ferrule. Leaves less residue than regular masking tape. I put the shaft inside a thick towel for padding, in a portable vise, not too tight, to be able to sand the tip down. I use 400 grit, and use a shoe-shine motion, constantly turning the shaft to take down the tip. Keep replacing the tape, because after a few turns, it's easy to go through the tape. This takes longer than blades, but most examples I've seen of those end up with gouged ferrules, or ferrules that look like bullets because sanding was done afterward to cover up the gouging.

Here's the tricky part. Because of the tape with every sanding turn, the tip will be slightly bigger, by the thickness of the tape, when you are about done. The next couple times you tape the ferrule, back the tape down the ferrule by about a millimeter or two, so that the final sanding flushes the tip with the ferrule. Don't worry, if you don't go too far, you will not contact the ferrule in any of this.

Next step, shape the tip. Everyone has their own favorite, and they all work. Also a medium cross file will work too. Don't go too fast. For burnishing, I wet the sides of the tip a bit and just turn underneath a folded paper towel a few times. I might put some magic marker ink on the sides; the examples above have that. But it isn't absolutely necessary. If I've put ink on, I go through the burnishing again a couple times."

That's it. Hope that helps.

All the best,

WW

Those look really great. You should totally write a guide. Would love to read something like that. What's wrapped around the ferrule? Just tape?

Deleted.......................

Last edited:

Hello all. I was wondering if you all Do it yourself when it comes to putting a new tip on your cue or do you have it done at a billiards shop, friend, league mate, etc? I have watched a few videos on YouTube from DIY, to professional retips. Some people use cutting tools while manually spinning the cue, others use a lathe. It doesn't seem like all that much trouble ,.....after you've done it a few times, but nobody wants to accidentally dig into the ferrule of their baby. I do have a lathe, but I do have a very nice kiridashi

I'm wondering if you DIY, how did you learn and how many attempts did it take for you to be confident? And I'm assuming you practiced on a like a bar cue ? Lol

I have Mike Webb take care of my tips! He made me the sickest shaft I have ever played! I've had it now for almost 3 yrs and it plays like the first day I got it.

I break with it, play, jump, and whatever I need to do on a shot and I don't hesitate!

I went through a few predators and treated them like babies because I had issues with them! Tough to jump, cracked shaft, and the white thing before the tip,,,whatever it's called!

I tried out a Mike Webb shaft and liked it so I had Mike build me 2. Since then, I feel my game improved(wether it's in my head or not, don't care)!

I have Mike replace my tip when needed (I think I'm on 4-5 or 6, idk)! I figure he built it, so in reality it's his baby and he knows how to make her happy! I get it back and it plays perfect for me!

I figure with the abuse I put it through he will be able to tell me how it's holding up, and so far it plays like the day I got it and he hasn't said anything to me! I'm confident that any other shaft would not be able to go through what this shaft has and still play, feel, shoot like it does!

I'm not trying to break this shaft, but sometimes I feel like I should of already! I've been playing for 11-12 yrs now and this is by far the longest time I've played with 1 shaft! Never had an issue. If it was a predator or anything else, it would of been replaced a while ago!

So to answer your question about doing my own tip or having someone do it? I have Mike Webb take care of it! This shaft deserves to go back to daddy for maintenance!

Eli