Hats off to you sir! I have and am currently lurkin on this! GOOD LUCK TO YOU !at this moment, I am thinking of something like this:

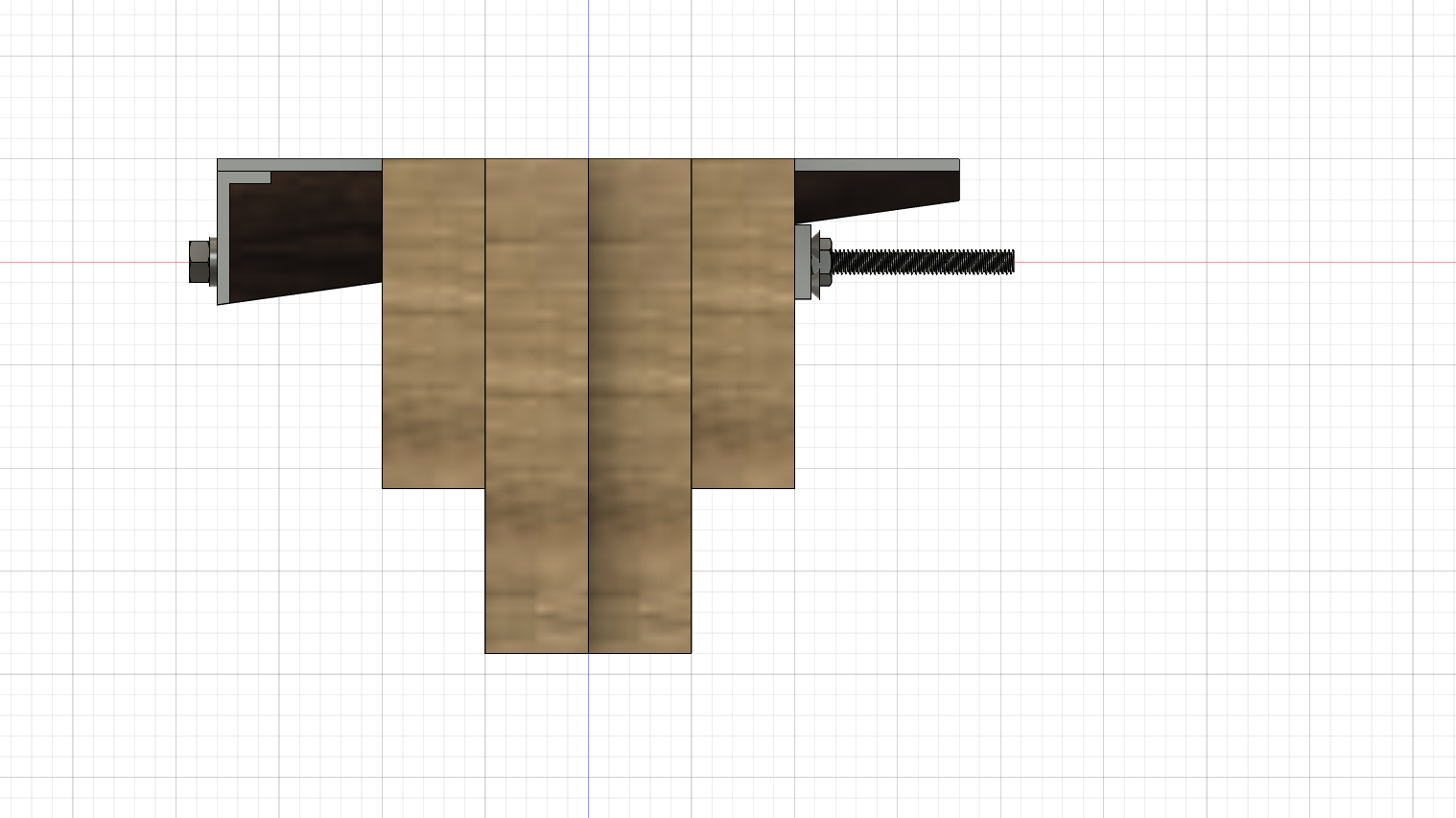

View attachment 614862

I like the idea that all slate pieces are equally supported and also for the slate levellers to be placed in a way symmetrical on both axis.

I drew the dimensions of the outside of that frame to be exactly 100" by 50" (254cmx127cm)

So the levellers on the side would be directly beneath the border of the playing field. I see no reason to put levellers on the complete outside of the slates, the wider they are put apart, the more possibility of bending. (theory of airy points)

I'm now thinking of 8 levellers for each slate, with an extra one in the middle for a total of 27 levellers.

Just a reminder for everyone: I'm designing with one word in mind = overkill.

TFT