You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

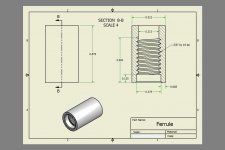

Ferrule design opinions

- Thread starter Canadian cue

- Start date

Ferrule Hang-Up

Just be sure that the guy following the Plan chamfers the 3/8" counterbore

like on the drawing, or the tendon might have to have a thread relief at the back shoulder ( thus, weakening the tendon). Maybe better to put a dimension on the plan like 3/32" x 45* chamfer or something to let the machinist know to chamfer the I.D.

Just be sure that the guy following the Plan chamfers the 3/8" counterbore

like on the drawing, or the tendon might have to have a thread relief at the back shoulder ( thus, weakening the tendon). Maybe better to put a dimension on the plan like 3/32" x 45* chamfer or something to let the machinist know to chamfer the I.D.

Thanks Sherm I corrected my mistake.

Cue caps I am the Machinist so I will be conscious of the size of the chamfer but thank you for the reminder.

Cue caps I am the Machinist so I will be conscious of the size of the chamfer but thank you for the reminder.

Thank you for informing me, at least I know it is a proven idea then. Do McDermott ferrules hold up well?KJ Cues said:Are you going to be supplying these to McDermott because that could be a print of their ferrule. Tweak a number here & there and you've got a McD. ferrule.

Since I've opened the door to the similarities btwn. your design and McDs., I should probably qualify it a little further.

Both McDermott and Meucci share the 3/8" tenon. Meucci's is unthreaded and McD's. is threaded only on the upper 1/2 of the ferrule. Your design brings the threaded portion closer to the base of the tenon. If your design were based on a 5/16" tenon, I'd then say it was a bad idea because the minor diameter of the threads is the weak link. The closer the weak link is to the base of the tenon, the weaker the structure becomes. While your design is based on a 3/8" tenon, it actually only has the strength of a 5/16" unthreaded tenon because 5/16" is the minor dia. of the 3/8" thrd.

OK, now to your question about the McD ferrule's strength. McD. uses a mtrl. called Ivorine which is quite strong. Your drawing is accurate in the wall thickness. Consider now that the owner of this shaft desires a turn-down to a smaller dia., say 12mm. This reduces the wall of the ferrule from .068" to .048". This starts to become an area of concern.

I'll give you something else to ponder. Both McD. & Meucci use an over-length ferrule/tenon. There is a phenomenon known as tenon leverage. Think of the tenon as a lever. Striking the QB. off-center causes the tenon to act as a lever to it's base. The longer the lever, the less force that is required to flex the tenon at it's base. Ferrule mtrl. strength will do nothing to lessen this effect. This is why ferrules snap off at their base.

Before my ramblings bore everyone to a state of unconsciousness I'll give you yet another consideration. Ferrule mtrl. weighs more than wood. The heavier the ferrule mtrl. the greater the deflection (of the QB) the shaft will produce. All performance shafts incorporate the principle of low front-end mass. This allows them to get off the ball quicker, thereby reducing deflection. The greater the weight of the ferrule, the greater the front-end mass. Conversely, the lighter the ferrule mtrl., the lighter the front-end mass.

Now, armed with this addition information, take a shot at designing the perfect ferrule. LOL. It's quite a dilemma.

Both McDermott and Meucci share the 3/8" tenon. Meucci's is unthreaded and McD's. is threaded only on the upper 1/2 of the ferrule. Your design brings the threaded portion closer to the base of the tenon. If your design were based on a 5/16" tenon, I'd then say it was a bad idea because the minor diameter of the threads is the weak link. The closer the weak link is to the base of the tenon, the weaker the structure becomes. While your design is based on a 3/8" tenon, it actually only has the strength of a 5/16" unthreaded tenon because 5/16" is the minor dia. of the 3/8" thrd.

OK, now to your question about the McD ferrule's strength. McD. uses a mtrl. called Ivorine which is quite strong. Your drawing is accurate in the wall thickness. Consider now that the owner of this shaft desires a turn-down to a smaller dia., say 12mm. This reduces the wall of the ferrule from .068" to .048". This starts to become an area of concern.

I'll give you something else to ponder. Both McD. & Meucci use an over-length ferrule/tenon. There is a phenomenon known as tenon leverage. Think of the tenon as a lever. Striking the QB. off-center causes the tenon to act as a lever to it's base. The longer the lever, the less force that is required to flex the tenon at it's base. Ferrule mtrl. strength will do nothing to lessen this effect. This is why ferrules snap off at their base.

Before my ramblings bore everyone to a state of unconsciousness I'll give you yet another consideration. Ferrule mtrl. weighs more than wood. The heavier the ferrule mtrl. the greater the deflection (of the QB) the shaft will produce. All performance shafts incorporate the principle of low front-end mass. This allows them to get off the ball quicker, thereby reducing deflection. The greater the weight of the ferrule, the greater the front-end mass. Conversely, the lighter the ferrule mtrl., the lighter the front-end mass.

Now, armed with this addition information, take a shot at designing the perfect ferrule. LOL. It's quite a dilemma.

IMHO if you have a good bond on the face of the ferrule and shaft there should be no weak point here...

Craig Fales said:IMHO if you have a good bond on the face of the ferrule and shaft there should be no weak point here...

I have found that this "Good bond" between face an ferrule seldom exists or, at least, not nearly as often as the cue maker/repair man may believe. When changing ferrules on cues, and I've done literally thousands over forty years, I cut them off on the lathe turning them down to the tenon. I turn down leaving about a 1/32 of ferrule on the end at the shaft and then just make a plunge cut to final depth removing this last bit of ferrule and squaring and facing the shaft at one time. Very often this last bit of ferrule doesn't need cut off however as it just slides off since the facing glue had been broken down before the ferrule need replacing. Often this is the problem when a player complains of hearing a noise from his tip believing there is an air pocket or something under the tip.

Dick

I could see that on a slip on {sleeved} type ferrule, however on threaded ferrules this shouldn't be any issue with well seasoned wood and a quality glue.rhncue said:I have found that this "Good bond" between face an ferrule seldom exists or, at least, not nearly as often as the cue maker/repair man may believe. When changing ferrules on cues, and I've done literally thousands over forty years, I cut them off on the lathe turning them down to the tenon. I turn down leaving about a 1/32 of ferrule on the end at the shaft and then just make a plunge cut to final depth removing this last bit of ferrule and squaring and facing the shaft at one time. Very often this last bit of ferrule doesn't need cut off however as it just slides off since the facing glue had been broken down before the ferrule need replacing. Often this is the problem when a player complains of hearing a noise from his tip believing there is an air pocket or something under the tip.

Dick

McD used a 3/8-10 thread and they run the solid alignment shoulder much longer than 1/8". As far as how it will hold up? I think that would depend on the material that you use. McD used fiber for year and although it did not crack 90% of the cues deeloped space between the ferrule and shaft shoulder as the ferrule shrank. Then they went to Ivorine three and have had some breakage problems, although most are holding up.

Last edited: