You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gold Crown IV Pro 8 Rebuild

- Thread starter coolidge

- Start date

coolidge

Well-known member

Much of what I need to practice has nothing to do with pocket width. Tightening the pockets would be counter productive for this. I already have pocket speed control and strive for clean shots in the center of the pocket never touching the pocket cushion anyway.

Now if/when the day comes that I want to tighten the pockets for practice I can 3D print pocket reducers for those practice sessions. I have a high end dual independent print head 3D printer so I can print the reducer with a rubber lining.

Now if/when the day comes that I want to tighten the pockets for practice I can 3D print pocket reducers for those practice sessions. I have a high end dual independent print head 3D printer so I can print the reducer with a rubber lining.

IMO, pocket reducers are a poor choice. The pockets will play terrible. Unless you plan on attempting a 14.1 high run, I'd think twice about the 5"/5.5" decision. It seems 4.5"/5" is today's "standard" for a pool table. The psychological aspect of going from large pockets to tighter pockets is real so wouldn't it be better to practice on conditions that are similar to those you'd be competing on? Is the real reason what you stated or are you not interested in the time it will take to do the work and the cost involved?Much of what I need to practice has nothing to do with pocket width. Tightening the pockets would be counter productive for this. I already have pocket speed control and strive for clean shots in the center of the pocket never touching the pocket cushion anyway.

Now if/when the day comes that I want to tighten the pockets for practice I can 3D print pocket reducers for those practice sessions. I have a high end dual independent print head 3D printer so I can print the reducer with a rubber lining.

coolidge

Well-known member

Cost is no object. I'm not a tournament player and never going to be a tournament player. I could change my mind on tightening the pockets I'll have to speak with RKC but for now I'm fine with 5 and 5.5. There are some other modifications I'd like to have done to the rails.IMO, pocket reducers are a poor choice. The pockets will play terrible. Unless you plan on attempting a 14.1 high run, I'd think twice about the 5"/5.5" decision. It seems 4.5"/5" is today's "standard" for a pool table. The psychological aspect of going from large pockets to tighter pockets is real so wouldn't it be better to practice on conditions that are similar to those you'd be competing on? Is the real reason what you stated or are you not interested in the time it will take to do the work and the cost involved?

One issue I do see on the side pockets is someone got carried away with a grinder so one edge (angle) is rounded instead of straight. That probably needs to be cleaned up straight then extended back out to the proper width.

Last edited:

coolidge

Well-known member

Any design you can imagine as you have complete 3D control over the shape and angles accurate to a few thousands of an inch in all dimensions. With dual independent print heads you can 3D print with 2 types of filaments simultaneously. Nylon/rubber, ABS/rubber. NOT a substitute for regular play imo. It's not going to play like a table with properly reduced pockets. But to narrow a pocket temporarily specifically for practicing sure.What would a 3d printed pocket reducer look like? I like that idea.

Can’t remember what it’s called but are you now going to have someone drag a slab of granite across it before the cloth goes down?

It’s called a machinists stone or lapping stone.

Sent from my iPad using Tapatalk

coolidge

Well-known member

Now where was I before the 6 week illness and 5 days in the hospital and 16 bags of IV antibiotics...BEHOLD the cloth is on!! I used the glue method, cloth indexing and RKC250 glue. Thankfully @realkingcobra wasn't around to see how much glue I wasted

coolidge

Well-known member

Yes I did manage to rub the skin off my knuckles stretching the cloth arrgh! Especially on the final end stretch which required cussing, sweating it kept popping loose. After applying some more glue it was MUCH easier, held like it was TIG welded then.

I also put some wax paper between the folded back cloth while I applied the glue to the cloth just in case any soaked through.

I also put some wax paper between the folded back cloth while I applied the glue to the cloth just in case any soaked through.

If your fingers were bleeding, you were installing it rightYes I did manage to rub the skin off my knuckles stretching the cloth arrgh! Especially on the final end stretch which required cussing, sweating it kept popping loose. After applying some more glue it was MUCH easier, held like it was TIG welded then.

I also put some wax paper between the folded back cloth while I applied the glue to the cloth just in case any soaked through.

coolidge

Well-known member

Thankfully both hands have scabbed over now. (face palm)If your fingers were bleeding, you were installing it right

When I was teaching the factory workers at Diamond how to recover the 7ft slates, id ask each of them, including Chad, the VP if they had it down pat stretching the cloth tight. They'd all tell me that got it, then I say show me your knuckles. When they did, if I didn't see any blood, I'd tell them, no you don't do some more slates, even Chad

When they started to get bleeding knuckles, then id tell them, yep, you got it now! It was only later that I showed them I use the vice grip duck billed pliers to grab the slate with so I didn't make MY knuckles bleed anymore

They asked me why I didn't show them the pliers in the first place, so I said, why mess up my fun of watching them all get bloody knuckles

When they started to get bleeding knuckles, then id tell them, yep, you got it now! It was only later that I showed them I use the vice grip duck billed pliers to grab the slate with so I didn't make MY knuckles bleed anymore

They asked me why I didn't show them the pliers in the first place, so I said, why mess up my fun of watching them all get bloody knuckles

coolidge

Well-known member

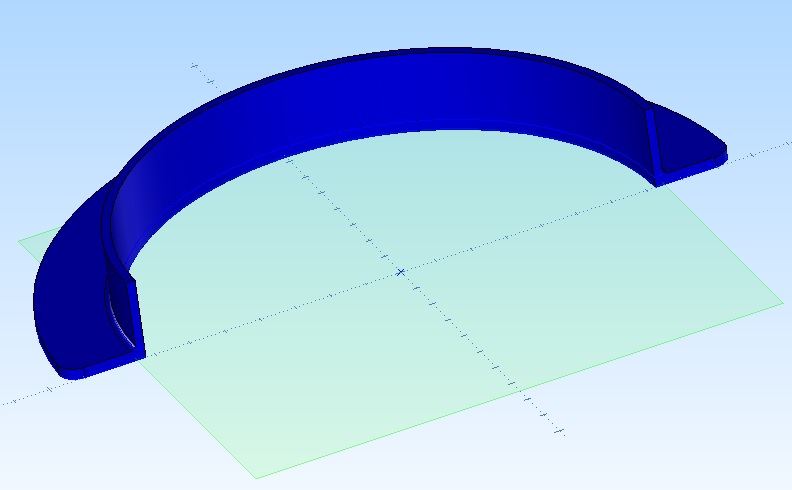

Tested a cloth skirt for the side pocket, not happening. The underlayment is both set back and tapered back and away from the vertical surface of the slate. Time for CAD and the 3D printer to get in the game. I have some Ultimaker black TPU 95A thermoplastic polyurethane filament, tough and flexible like rubber. I'm off to print one of these...

Alrighr

Alright, now you're just showing offTested a cloth skirt for the side pocket, not happening. The underlayment is both set back and tapered back and away from the vertical surface of the slate. Time for CAD and the 3D printer to get in the game. I have some Ultimaker black TPU 95A thermoplastic polyurethane filament, tough and flexible like rubber. I'm off to print one of these...

View attachment 634796

I've built that gap up in the past with 1/6" × 3/4" slices of poplar wood bent, and layered in place, then belt sanded to profile.

Go tighter! At least 4.5"/5". If you leave it at 5"/5.5", you're gonna be hurting if you go to an event and they are using Diamonds or tighter equipment.

Face angle is more important than pocket size in determining difficulty of the table imo. I.e. The pictured pocket's (corner) are almost approaching parallel which would make them play far easier than even a much larger pocket opening but w/greater Face angle. It's a fine balance with multiple factors contributing besides just opening size.