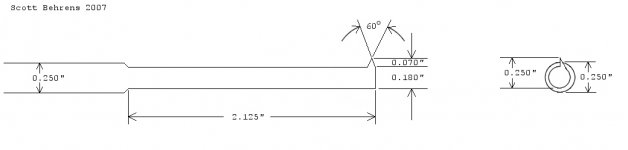

I haven't done this yet and need to pick up a tool for doing it. I'd like to get the tightest fit possible to the 3/8-10 pin. Here's what I've come up with. I figure this will cut in a minimum bore size of .250 and should have enough tooth to get all the thread cut. 2 inches of depth so a 3 inch pin can be put in 2 inches with 1" left for the shaft attachment. Thoughts and comments from those who've done it would be greatly appreciated.

Thanks,

Scott

Thanks,

Scott

Attachments

Last edited: