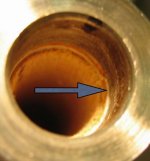

I have a customer who bought a cheap cue on ebay with a crooked joint screw. He wants me to fix it. I know once I take the screw out, it will be a simple matter of indicating the cue so it runs true, boring out the opening, gluing in a plug, and retapping the threads. I can handle that without any problems.

The problem is removing the joint screw. I practiced on a broken McDermot I had. I heated up the screw with a propane torch. The torch has a "gun" attachment so it has a more focused flame than the regular "paint burning" attachment. I was able to unscrew the pin after heating it sufficiently.

Then I tried it on the customers cue and I couldn't unscrew it. The screw got plenty hot, but it would not budge. I didn't grip it super tight as I didn't want to damage it incase I couldn't remove it. Where as on the practice cue I used a pair of vise grips.

Is there a better techinque?

Thanks,

Nick

The problem is removing the joint screw. I practiced on a broken McDermot I had. I heated up the screw with a propane torch. The torch has a "gun" attachment so it has a more focused flame than the regular "paint burning" attachment. I was able to unscrew the pin after heating it sufficiently.

Then I tried it on the customers cue and I couldn't unscrew it. The screw got plenty hot, but it would not budge. I didn't grip it super tight as I didn't want to damage it incase I couldn't remove it. Where as on the practice cue I used a pair of vise grips.

Is there a better techinque?

Thanks,

Nick