You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

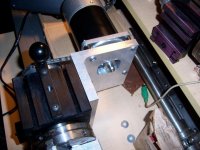

motor

- Thread starter treed

- Start date

i need a small motor for a repair lathe,would like it to be variable speed and revesible w/ a controller.anyone have one or know of a good source?

http://www.pennstateind.com/store/TCLVSKIT.html

I bought one of these and it works great on my spinner.

Be aware that you will have to make a mount for the motor, a pulley for the motor and a reversing switch. It doesn't come with any of these.

I have pics if you need them.

Kim

thanx fellas,i like the penn state motor,but i found what i was lookin for,for anybody thats interested check out wonder motors.i switched a sewing machine motor on a small repair lathe out to one of these a couple of years ago,works great.

I've got one on another lathe that I have been putting together. I've got the mount & control box parts machined, and put together. I'm working on making taper bars for It now. I've got the parts for the butt, and shaft bars, just waiting on the solid bar to mount them on to get here, so I can start fabricating those.

It works very well so far. I have My concerns with the long term durability of the motor, but so far It seems very powerful for the size. It won't be used for any hard core drilling or boring though, so hopefully It will hold up for a while.

Attachments

I can promise it doesn't get any better than custom cue lathes 1/3hp motors as far as size and hp are concerned.

Motor

What I would like to know is where to get the face plate with the tach and controls.

What I would like to know is where to get the face plate with the tach and controls.

That control unit and panel come with the motor as a package. Here are the specs... http://www.wondermotor.com/ecm_motor.html

Last edited:

I made the bracket & control panel on mine out of aluminum. I also had to change the inside bore of a pulley to work on the motor spindle. I used bearing spacers for the standoffs to make space for the belt.

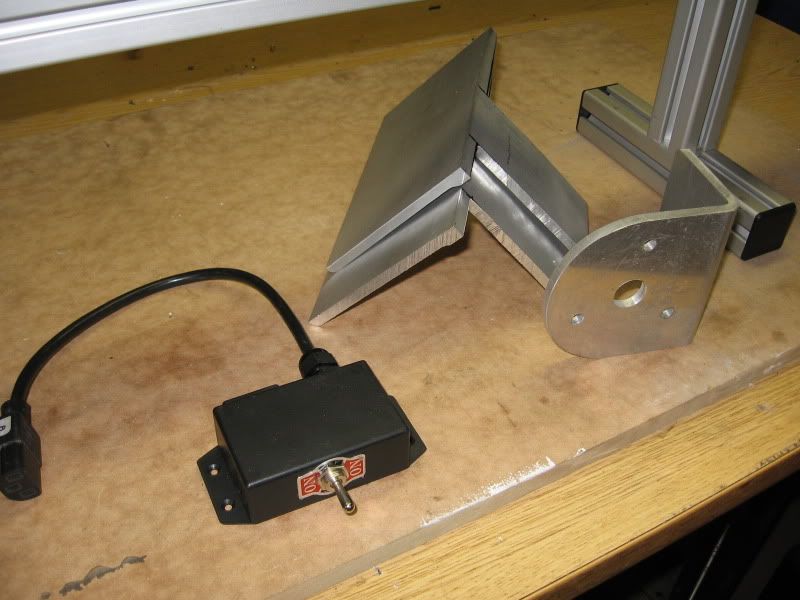

Here are some old progress pictures of the bracket. I don't have one of the control panel in progress, just the finished product that I posted before, but it's really nothing special. It pretty simple. It consists of 2 thicker pieces of aluminum cut at an angle for the sides then I covered the top, bottom, front, and back with thinner 1/8" thick or so aluminum. Making the sides from a thicker piece gave Me a decent base to drill and tap into. You could just use a electronic project box to mount the panel if needed.

Here are some old progress pictures of the bracket. I don't have one of the control panel in progress, just the finished product that I posted before, but it's really nothing special. It pretty simple. It consists of 2 thicker pieces of aluminum cut at an angle for the sides then I covered the top, bottom, front, and back with thinner 1/8" thick or so aluminum. Making the sides from a thicker piece gave Me a decent base to drill and tap into. You could just use a electronic project box to mount the panel if needed.

Attachments

my motor mount

I didn't have the metal to make a motor mount but I had 3/4 inch oak plywood.

Don't laugh........ it works perfectly. I made the mount, turned the motor pully on my lathe, installed the reversing switch, and bought a belt (2L-200) on Ebay. I have a foot pedal switch so I can use it for wraps, sanding, and finishing.

Kim

I didn't have the metal to make a motor mount but I had 3/4 inch oak plywood.

Don't laugh........ it works perfectly. I made the mount, turned the motor pully on my lathe, installed the reversing switch, and bought a belt (2L-200) on Ebay. I have a foot pedal switch so I can use it for wraps, sanding, and finishing.

Kim

Last edited:

Hey..... top notch mount..................

just a note.... I adjusted the controller to get a slower speed. There are 3 pots. It's the little pot next to the big capacitor. Clockwise is slower (I think). One is max speed and I don't know what the other one is.............

maybe some one has some more information............

Kim

Last edited:

That control unit and panel come with the motor as a package. Here are the specs... http://www.wondermotor.com/ecm_motor.html

Whe wonder motor with controller looks great, but last time I tested one, it was very weak and underpowered. I sold one lathe with a wonder motor. The motor only lasted one week. Their rep in CA would not honor the warranty.

I have them all in a box collecting dust.

Once I found my 1/3 HP DC motor / controller, I never looked back.

Sold over 100 motors in the last 2.5 years with 0 returns.

I have 4 or 5 wonder motors, I would sell them for $100 plus shipping

I also have 4 penn state motors, with no controllers, 3 are brand new and one is almost new.

Motor alone $55 plus shipping

My 1/3 HP DC motor with speed controller and reverse switch $139 plus shipping.

Best Regards

Bassel

Custom Cue Lathes

Www.customcuelathes.com

Customcuelathes@yahoo.com

248-884-4469