couple guys were wondering about the technique.

1. Start off RPM's on the slow side, then find what you are comfortable with(I use around 600).

2. While I'm sure you can freehand the operation, I like to have a piece of barstock mounted in a tool post to steady everything.

3. Use your fingers behind the ferrule to prevent push off and chatter.

4. Lay the tool at about 30 or so degrees on the ferrule. The flat side won't/can't cut anything as long as you keep it flat.

5. Begin cutting tip. The trick is to keep the blade flat. This is what the cut relies on. If you cut the tip flat at the beginning and continue in the same fashion, it will all be flat. Each kind of tip is different. If you experience chatter at the end, you are most likely not pushing with enough pressure or cutting fast enough. This usually happens near the end of the tip in an area you would cut away for shape.

6. It may take more than one pass, but usually not more than two. If you are cutting a Ki-tech soft, I'd probably move to a razor blade after the first cut gets the base flush. Dewalt carbide are recommended.

I realize there are guys out there that can do a great job with razor blades. However, the thing I like about these is that as long as they are laid flat, nothing bad can happen.

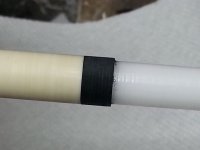

The top is a triangle

Black layered is an Ultraskin M

I did these pretty fast so I could post this, so they are not PERFECT.

ferrule and shaftwood was junk I had laying around. NO real shaftwood or Juma was hurt during these proceedings