You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

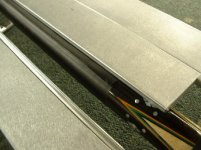

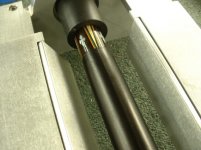

My New Porper Leather Wrapping Fixture

- Thread starter ratcues

- Start date

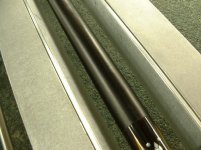

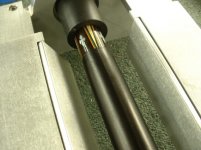

To keep the cue from rotating during the seam cut, there is a thumb screw that fits into a channel in the rear collet. That locks the cue in place.

This is the point where Joe, himself, called to walk me through the process since the instruction booklet was not quite ready when he shipped the machine to me. I had it figured out, for the most part, so all I had to do was press the seam.

This is the point where Joe, himself, called to walk me through the process since the instruction booklet was not quite ready when he shipped the machine to me. I had it figured out, for the most part, so all I had to do was press the seam.

It certainly looks like a very nice machine. My only question is how do you get glue on the edges (on the ends) using this if you cut them in the machine. I would think that the wrap must be glued down for control purposes before cutting the leather.

The first jig I made years ago had a similar cutting blade but I stopped using it because of the lack of glue on the ends of the leather. Now I cut the leather to length using the template most of us all use which allows us to apply glue the edges of the leather before installation.

Good Cuemaking,

The first jig I made years ago had a similar cutting blade but I stopped using it because of the lack of glue on the ends of the leather. Now I cut the leather to length using the template most of us all use which allows us to apply glue the edges of the leather before installation.

Good Cuemaking,

Gotta love a new toy I mean tool.

It looks Like a great investment, thanks or the pics.

It looks Like a great investment, thanks or the pics.

Jr's Farm said:Is there a way to set a stop for the length cutter? I don't see a way to set a stop or lock into place.

Regards,

Frank

Yes, there is a thumb screw that locks the arm in place, on the slide bar.

Arnot Wadsworth said:It certainly looks like a very nice machine. My only question is how do you get glue on the edges (on the ends) using this if you cut them in the machine. I would think that the wrap must be glued down for control purposes before cutting the leather.

Yes, the wrap has to be glued to keep it from moving but, depending on your glues tack timeand strength, you should be able to lift it slightly to touch up the edges.

I just got it and installed that wrap within 15 minutes of taking it out of the box so I suppose there will be an adjustment period, as there would be with any new process. I mean, I do not use any sort of jig or template to do leather so this was quite a change for me.

look very nice...

does the cutting blade changeable?

if you score this machine , which points you rating?

(0 to 100)

have any drawbacks? (except price)

because I have Uniqueinc Wrap Machine

although this machine look very nice , but I want heart your suggestion

does the cutting blade changeable?

if you score this machine , which points you rating?

(0 to 100)

have any drawbacks? (except price)

because I have Uniqueinc Wrap Machine

although this machine look very nice , but I want heart your suggestion

Adonisy said:look very nice...

does the cutting blade changeable?

if you score this machine , which points you rating?

(0 to 100)

have any drawbacks? (except price)

because I have Uniqueinc Wrap Machine

although this machine look very nice , but I want heart your suggestion

The blade has 360 degrees of cutting surface so you can loosen the screw and rotate it slightly. Once it makes it completely around, it can be replaced.

I have no way to really rate the machine because I do not use a fixture so this is a first for me. It seems easy enough to use. It looks durable, as most of Joe's inventions are.

The only drawback I foresee is that the collets are sized to fit the average butt. That being said, the Delrin collect can be removed and I am sure a larger or smaller set could be made or modified. That is an easy enough fix.

Adonisy said:look very nice...

does the cutting blade changeable?

if you score this machine , which points you rating?

(0 to 100)

have any drawbacks? (except price)

because I have Unique inc Wrap Machine

although this machine look very nice , but I want heart your suggestion

you mention price $700.00 is very fair for this machine we had plans of our machine selling for $550.00 and we just could not do it for that and this does more then ours just think 7 wraps its paid for life!!! cheap investment for what it does . if this cuts your time down and lets you move on to other things making money. the cue business is not for the financially weak at heart!!!!!!!!!

Last edited:

ratcues said:Since my initial post, I have used this machine to install 5 wraps. Three more and its paid for.......

What would you say your labor time started at, and how been cut down to, to install a leather wrap?

shakes said:What would you say your labor time started at, and how been cut down to, to install a leather wrap?

I need to qualify my answer first. Understand that I have been doing leather wraps the exact same way for 12 years. I'm pretty efficient at what I do. I have to be or I'll get buried.

That being said, I can do a wrap on this machine in about 15-20 minutes start to finish. I'm getting better and faster each time. I've had a few people come to the shop and check it out (BTW, you are all invited) and I feel that it would be easier for them to learn how to use it rather than retrain me.

Also, I've learned that I true on edge of the wrap and set it in the channel and use the cutting arm to cut the other end. That worked a little better for me because I could set the cutting arm in position as opposed to setting it, cutting, moving it, setting, cutting. I can get some pics of that, if necessary. Let me know.

A second thing I learned on Monday is that the blade is very, very, very, sharp. Cuts through flesh like nobody's business. (if you want to build cues and make money, buy stock in Johnson+Johnson, maker of Band-aids:embarrassed2: )

ratcues said:I need to qualify my answer first. Understand that I have been doing leather wraps the exact same way for 12 years. I'm pretty efficient at what I do. I have to be or I'll get buried.

That being said, I can do a wrap on this machine in about 15-20 minutes start to finish. I'm getting better and faster each time. I've had a few people come to the shop and check it out (BTW, you are all invited) and I feel that it would be easier for them to learn how to use it rather than retrain me.

Also, I've learned that I true on edge of the wrap and set it in the channel and use the cutting arm to cut the other end. That worked a little better for me because I could set the cutting arm in position as opposed to setting it, cutting, moving it, setting, cutting. I can get some pics of that, if necessary. Let me know.

A second thing I learned on Monday is that the blade is very, very, very, sharp. Cuts through flesh like nobody's business. (if you want to build cues and make money, buy stock in Johnson+Johnson, maker of Band-aids:embarrassed2: )

The invite is much appreciated, if I'm ever your way, I may just take you up on it. Actually, what I was asking was more along the lines of how much time are you saving using the wrap fixture as opposed to before the wrap fixture? I know you've been doing it a long time, and the amount of time saved for you may not be as much as your average joe who hasn't been doing it as long, I was just curious.

Thanks!