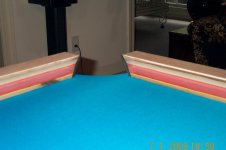

Just got through with my table rehab, except for recovering the rails and wanted to share my work, get feedback, and give props to everyone here that made this possible (especially RKC).

I don't have pics of the leveling process, but I used RKC's method, and I got the overall level (machinist's level on top of a 6' box beam level) within +- 1/2 division on the vial, and the level anywhere on the slate with the machinist's level alone +- 1 division on the vial.

I super-glued the slate seams and since there was a major blow-out in the playing area, I used bondo to finish the seams as well as to fix any other imperfections in the surface. I didn't want to take a chance on a ball making a dimple in wax at the blow-out. I did cut some paper and covered the slate screw heads before filling in the holes in the center of the slate.

The next step was the cloth. I decided to glue the cloth since the more I thought about it, the more sense it made in terms of being able to get a really good stretch on the cloth. I used 860HR, and calculated a 2 3/4" stretch for an 8' OS table based upon RKC getting a 3-inch stretch on a 9' table. I ended up getting somewhere between 2 1/4" and 2 1/2" of stretch, and it was a *****! I didn't bark my knuckles, but my fingers hurt for two days afterwards, and the cloth seems tight as a drum.

While I was at it, I put Artemis Pool 66 cushions on, and replaced the facings with 3/16" neoprene with a durometer rating of 60A. Grainger sells this in 3"x36" strips and one strip was just enough for a single table. My pockets were originally to BCA specs, and although I didn't particularly want to tighten them up, I did want to go thicker based upon RKC's experience with 1/8" facings stencil-cutting the cloth.

All I have left now is to cover the rails, and I'll be in business. I will add pics of the rails once I get those done...

I don't have pics of the leveling process, but I used RKC's method, and I got the overall level (machinist's level on top of a 6' box beam level) within +- 1/2 division on the vial, and the level anywhere on the slate with the machinist's level alone +- 1 division on the vial.

I super-glued the slate seams and since there was a major blow-out in the playing area, I used bondo to finish the seams as well as to fix any other imperfections in the surface. I didn't want to take a chance on a ball making a dimple in wax at the blow-out. I did cut some paper and covered the slate screw heads before filling in the holes in the center of the slate.

The next step was the cloth. I decided to glue the cloth since the more I thought about it, the more sense it made in terms of being able to get a really good stretch on the cloth. I used 860HR, and calculated a 2 3/4" stretch for an 8' OS table based upon RKC getting a 3-inch stretch on a 9' table. I ended up getting somewhere between 2 1/4" and 2 1/2" of stretch, and it was a *****! I didn't bark my knuckles, but my fingers hurt for two days afterwards, and the cloth seems tight as a drum.

While I was at it, I put Artemis Pool 66 cushions on, and replaced the facings with 3/16" neoprene with a durometer rating of 60A. Grainger sells this in 3"x36" strips and one strip was just enough for a single table. My pockets were originally to BCA specs, and although I didn't particularly want to tighten them up, I did want to go thicker based upon RKC's experience with 1/8" facings stencil-cutting the cloth.

All I have left now is to cover the rails, and I'll be in business. I will add pics of the rails once I get those done...

Last edited: