Hi,

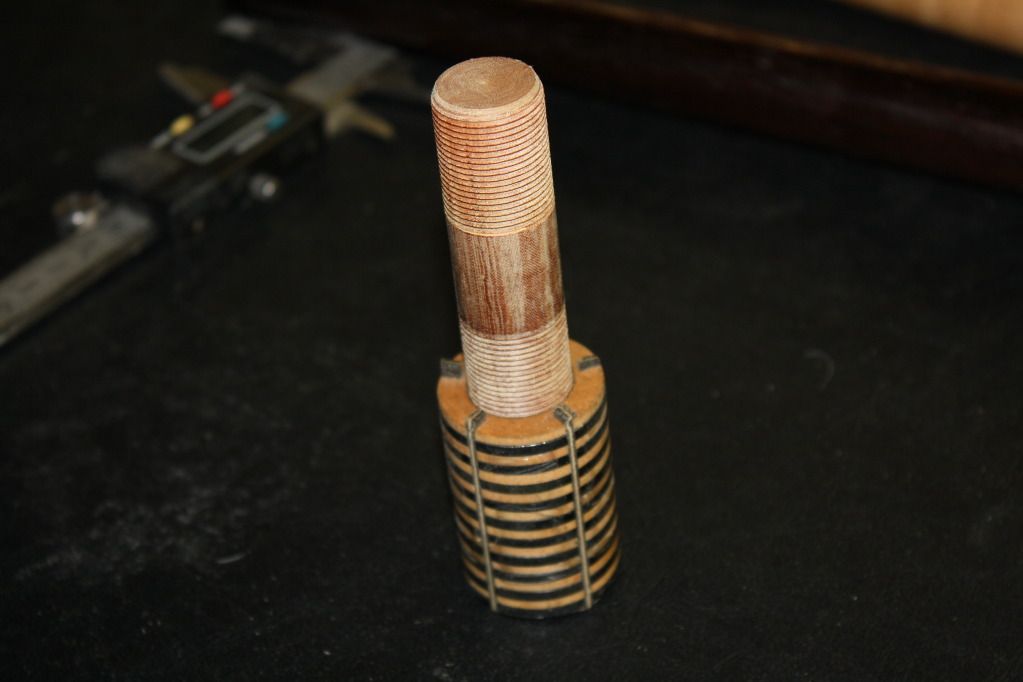

I have had a lot of Omega DPK stuff come through my shop over the years because of my proximity to Waconda and people I have known over the years who had ties with Omega. One of the most interestiing things was this blank that was never glued at the A-Joint

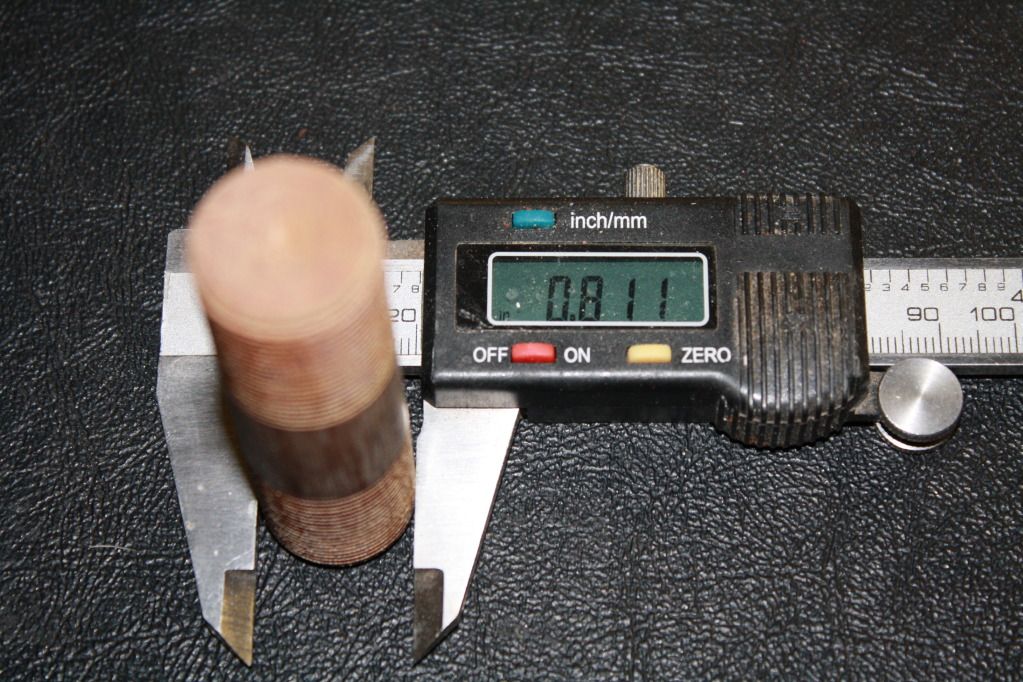

Omega used a phenolic rod turned down to .811 and it is live threaded for the construction and tension interface with the id of the handle matching threads. I believe they added tungsten powder to epoxy and filled this rod for the weight they wanted to add from the other end when they glue up.

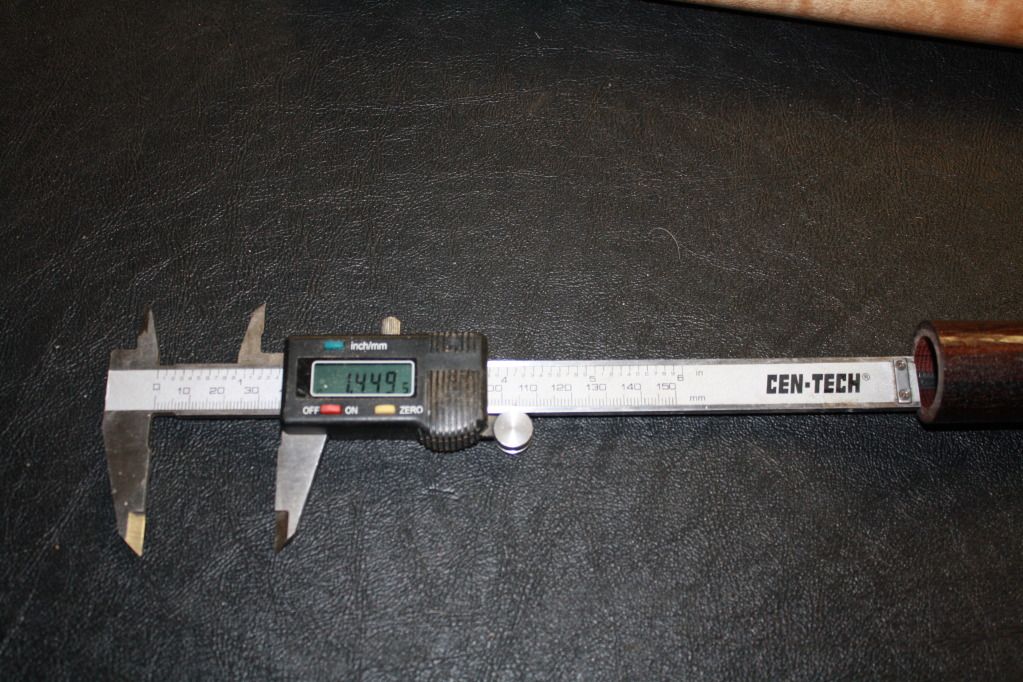

Someone gave me an Omega Ring Billet many years ago and I was puzzled why the ID was .815. Now I see the method to the concept.

Rick G

Joined blank before gluing

A-Joint revealed using phenolic threaded rod

Billet in foreground is a OMEGA DPK unit with .850 ID.

Omega DPK business sign autographed by Dallas, Don Feney, Vivian Valaria, and the man himself, DPK.

Proto type FS Blank from Omega:

I have had a lot of Omega DPK stuff come through my shop over the years because of my proximity to Waconda and people I have known over the years who had ties with Omega. One of the most interestiing things was this blank that was never glued at the A-Joint

Omega used a phenolic rod turned down to .811 and it is live threaded for the construction and tension interface with the id of the handle matching threads. I believe they added tungsten powder to epoxy and filled this rod for the weight they wanted to add from the other end when they glue up.

Someone gave me an Omega Ring Billet many years ago and I was puzzled why the ID was .815. Now I see the method to the concept.

Rick G

Joined blank before gluing

A-Joint revealed using phenolic threaded rod

Billet in foreground is a OMEGA DPK unit with .850 ID.

Omega DPK business sign autographed by Dallas, Don Feney, Vivian Valaria, and the man himself, DPK.

Proto type FS Blank from Omega:

Last edited: