Ive been facing and pressing my rings on cues in my main lathe for a while and the 10 minute drying time ties it up a bit. Does anyone have a jig theyd like to share to take the butt out of the lathe and press the rings tightly? Had a buddy helping the other day and he stood aroung more than he worked. Was thinking of a hollow tube maybe .800 thru and tight again something and then pressure the butt and ring into that dowel. My main concern is the pressure achieved. Thanks for any help guys and have a wonderful Sunday.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pressing rings

- Thread starter kiinstructor

- Start date

Since I core handles and forearms, I always have some hollow wood laying around. I make a hollow tube like you described out of delrin about 3 to 4 inchs long. That goes next to the rings, then a cored whatever comes next. All this gets placed in a bar clamp for 24 hrs. Just a small rap on the delrin is all it takes to release it from the epoxy.

Alan

Phelps Custom Cues

Alan

Phelps Custom Cues

RBC

Deceased

Over the years, I've done several different things.

I've used bar clamps with special little pads. They worked good, but are a pain in the but. And, you have to have a bunch of them.

I made a rack with 10 stations vertically. Each had a screw at the top to screw down and tighten on the cue. The first problem is that it bows too much. When you tighten up one cue it's great, but as soon as you tighten the second cue, the first one loosens up again, etc. This can be fixed by putting a heavy spring on each station so even if the frame bows, the springs are applying the pressure and will make up for the give in the frame. It worked well, but it gets epoxy all over it, and it takes up space. Overall I didn't like it too much.

The best solution, and it's not always the easiest, is to thread all your collars on. It takes some planning and setting up some equipment, but not only does it make the clamping of rings and such a no brainer, but it also makes your over all product tighter and stronger. The threads not only provide better clamping, but also much more surface area for the epoxy or whatever type of adhesive you use.

Just my thoughts

I've used bar clamps with special little pads. They worked good, but are a pain in the but. And, you have to have a bunch of them.

I made a rack with 10 stations vertically. Each had a screw at the top to screw down and tighten on the cue. The first problem is that it bows too much. When you tighten up one cue it's great, but as soon as you tighten the second cue, the first one loosens up again, etc. This can be fixed by putting a heavy spring on each station so even if the frame bows, the springs are applying the pressure and will make up for the give in the frame. It worked well, but it gets epoxy all over it, and it takes up space. Overall I didn't like it too much.

The best solution, and it's not always the easiest, is to thread all your collars on. It takes some planning and setting up some equipment, but not only does it make the clamping of rings and such a no brainer, but it also makes your over all product tighter and stronger. The threads not only provide better clamping, but also much more surface area for the epoxy or whatever type of adhesive you use.

Just my thoughts

I used to use a pipe vice, I made a delrin piece to go between the vice end and the cue. You just cant use to much pressure or it puts stress on the cue. It will hold it tight till the glue dries.

I have made up pieces of delrin that's big on one end, and then turned to the ID of the rings, and on the other end I drilled and tapped it. I have a end piece that's larger then the tenon with a threaded bolt that threads onto that piece, and made up spacers that resemble collets only they are not split. I made them in different sizes. Those are to accommodate different thickness rings. If I'm doing segmented dash rings that need to be aligned perfectly, then due to the way the clamp is tightened I have to use extra delrin slip washers on each side to help prevent them from turning, and becoming misaligned while the clamp is tightened. Solid color rings It doesn't really matter as much. The same thing could be made for more traditional pressing or clamping as opposed to the threaded type clamp though.

Thanks everybody for your help and replies. Im gonna try to make some jig to do the job. When I do I will post it and let you guys have at it. Just gotta free up that big lathe. hate to sit and triddle my thumbs while the glue sets.

Thanks everybody for your help and replies. Im gonna try to make some jig to do the job. When I do I will post it and let you guys have at it. Just gotta free up that big lathe. hate to sit and triddle my thumbs while the glue sets.

It would be kinda cool to see the different ones everybody has made up. I've made a few of my own but just reading the descriptions given by the different cue makers gives me ideas to make mine better. Some pics would even make it more helpful.

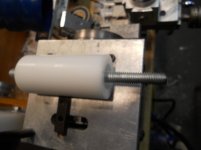

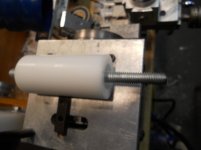

This is what I use, a delrin sleeve that is .820 I.D. and has about 2.5" depth and is threaded on one end with 3/8 x 16 tpi. I drill and thread about 1-2" in the butt of the cue, as most weight bolts I use are that same thread, and then glue and stack the rings and thread this on. It compresses very well and frees up the lathe while it dries. I then have a PVC pipe with the endcap screwed to the counter and that holds the cue upright while drying. I also have one made up for the rings at the joint end with a 3/8x10 tapped hole in it. Works for the shaft also.

Dave

Dave

thats pretty slick Dave. The problem I have is that I start with a 20 inch piece and gradually cut it to .750 leaving about 2 inches on one end which is the forearm end. Then I add sleeves and rings of various thickness to that all being .752 Id. These just slip over the dowel and I keep adding until I have the backpart of the cue constructed. But each time I add something I want to reface it so there are no glue lines or tolerances and I just reverse it in the chuck and use a delrin collar so as not to get any glue on the chuck and then twiddle my thumbs til the expoxy sets up. Well actually I do other things but Im still tieing up that lathe. I know one thing that its a machine lathe and the tail stock puts alot of pressure on the ring or whatever and the devil cant push it any tighter. Im satisfied the its solid.

Dave, Your method works pretty much the same as mine, only My fixture is stand alone, and glues the assemblies before going into the cue. same principal though. I originally came up with It for gluing, and lining up segmented rings into mini assemblies before gluing them into the cue. It was a lot easier for me to line them up before hand, although I do still have to line the assemblies up with each other when I actually glue them into the cue, but It's a lot easier to line 4 dashes up, as opposed to three times that many or more. I will say though, even with the delrin , the jig can sometimes be a pain to clean when I have to reuse It.