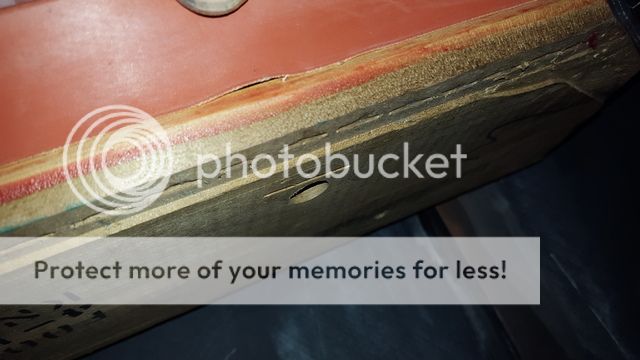

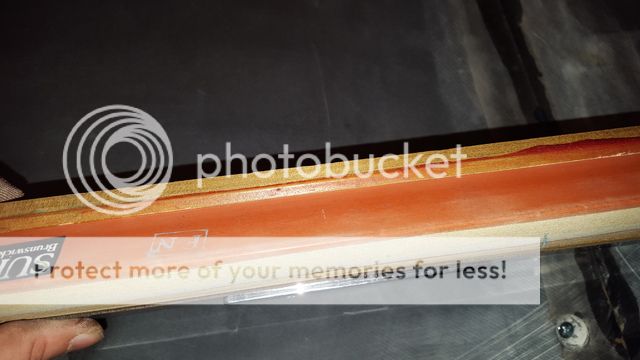

I recently purchased a 1973 brunswick monticello table. The cloth was faded bad so i figured id recloth it with 860hr.yes i am following the simonis videos. I also noticed in a couple areas the cushion makes more of a thud sound. I was thinking the cushions should be replaced. When taking the cloth off the cushions i noticed that they werent the original monarch superspeeds the table says it was made with but had the newer superspeed cushions and they look like they are in great condition however in a few areas where i heard the thud sound is because the glue is popped in those areas. Not horribly but in like a 1-2 inch length along the bottom seam where i can lift the rubber.

1.Now my question is can i just reglue these areas or should i remove the whole rubber and reglue if possible? Most of the rubber is glued solid and not a prob. I do have some penquin cushion glue on hand. I also noticed on the head and foot rails when taking apart that the center rail bolt was not installed,reason for this?

2On this table i seem to get a lot of balls rattling in the corner pockets.Much more then the GC4 tables i play on at the pool hall. Is there anything i can do to help that while i have it apart like with the angles or changing the cushion facings?

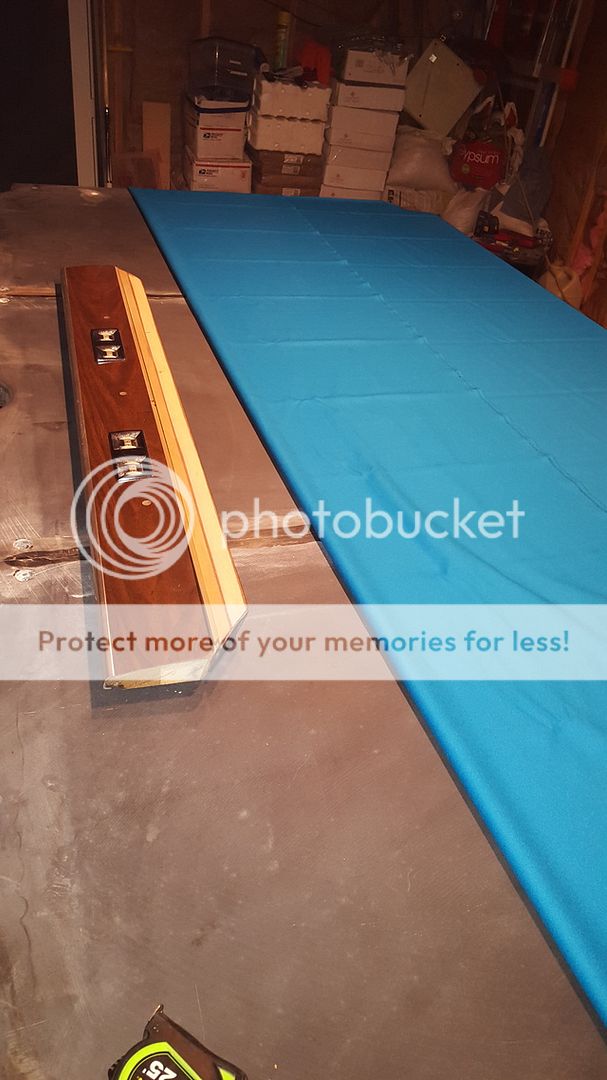

3When i had the table installed (by "pro" installers) they only put less then half the amount of slate screws. most holes are empty.They told me at the time it was standard practice to only put screws at the end of the slate and the other holes werent needed. Have any of you heard of anyone doing this before? I believe they used 4 screws per slate piece.They didnt seem to me to really be pros .reputable company but they apparently send the rookies instead of the experienced guys. Wasnt sure if they were just bad or me being the perfectionist machinist that i am.

Just trying to get this table playing as good as possible not that its playing horribly though.

1.Now my question is can i just reglue these areas or should i remove the whole rubber and reglue if possible? Most of the rubber is glued solid and not a prob. I do have some penquin cushion glue on hand. I also noticed on the head and foot rails when taking apart that the center rail bolt was not installed,reason for this?

2On this table i seem to get a lot of balls rattling in the corner pockets.Much more then the GC4 tables i play on at the pool hall. Is there anything i can do to help that while i have it apart like with the angles or changing the cushion facings?

3When i had the table installed (by "pro" installers) they only put less then half the amount of slate screws. most holes are empty.They told me at the time it was standard practice to only put screws at the end of the slate and the other holes werent needed. Have any of you heard of anyone doing this before? I believe they used 4 screws per slate piece.They didnt seem to me to really be pros .reputable company but they apparently send the rookies instead of the experienced guys. Wasnt sure if they were just bad or me being the perfectionist machinist that i am.

Just trying to get this table playing as good as possible not that its playing horribly though.

Last edited: