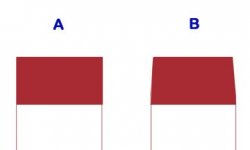

i have a very good friend who does lots of repair work. i never let him do my tips. why?,,,,because he can't put them on flush to the ferrule(A). i think his reasoning is that he would scratch the ferrule if he tried.

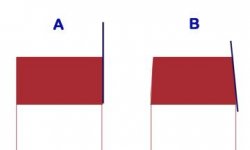

this is what he tells me, so as a workaround, he tapers the tip(B). i hate this for many reasons, and i don't have anyone to do my tips as a result.

can you help me,,,,,,HIM!!,,,and tell me how to install a tip flush to the ferrule?

thanks

this is what he tells me, so as a workaround, he tapers the tip(B). i hate this for many reasons, and i don't have anyone to do my tips as a result.

can you help me,,,,,,HIM!!,,,and tell me how to install a tip flush to the ferrule?

thanks