Every TS Custom Cue has Timi's trademark.

This was something Timi believed. If he built it he logoed it. He did build a very few unlogoed cues for friends like Joe Salazar.

No logo, no Scruggs. If Timi rembers differantly I will be sure to relay it but can't gaurentee rembering to ask.

Nick

Sir you are VERY wrong on this one.

In extensive searching of TS cues I have seen several no logo cues. Blue book of cues says in 78-early 79 he many cues without logos, mostly plainer cues like these 2. This is a paragrapgh from the online BBOC's website regarding the first years of Scruggs cues:

"In 1978, Tim decided to start making cues of his own. He went to visit with another young cuemaker, and friend, for many years. After this visit, Tim returned to Baltimore to set up shop. Bob Fry, a friend of Tim´s since the sixth grade, offered to help Tim to start making cues. That same year, Tim Scruggs Custom Cues was founded in an old meat storage building on the outer edge of Baltimore.

Early Tim Scruggs cues were similar to the cues he was making at Joss, but they were unmarked. Soon his cues developed their own unique style, and began a series of ongoing improvements. By the early 1980s, an intertwined "TS" was being stamped on the Delrin butt caps."

When the first catalog came out in 1980 the first cue below on the left was very similar to the cue on the bottoom of photo with the black then white then black thin ring at the butt cap. It isn't repeated up the cue. I've seen the thin black and white rings on the butts of his cues for his entire history.

The fancy ringwork near the joint on my cues are in essentially the same pateern as cues 9 +10 from the left. These are classic Scruggs 5 layer rings, that since the earliest cues predominantly includes silver rings. Who else was making fancy rings in this pattern at this time? To me the rings were part of his identity as a cuemaker, that continued until his retirement. That makes these unmarked cues some of the first that were constructed in this manner.

The hardware on these 2 cues including the buttcap, bumpers, steel joints and brass insets are the same as many early stamped TS Srcuggs that I have seen.

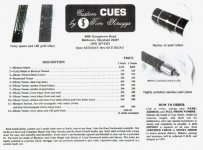

See this first catalog from january 1980 is shown below from classiccues website. The detail of the cues can be seen with much more clarity on their site, including the black white black rings at the base of cue 1. Check the following link:

http://www.classiccues.com/graphics/cues/cue_related/cues_brochures/ts_1980_inside1_hi.jpg

These cues are vintage, as evidenced by their current condition. Did somebody copy scruggs cues at a time when he was just starting out, knowing someday he'd be one of the greats? Sounds far fetched to me sir.