I just moved a 1300 pound lathe roughly 18 feet and up one stair using a pry bar and a couple metal pipes. My back will never be the same

View attachment 691023 View attachment 691024 View attachment 691025

Evaporust is some cool stuff. And there was 1 live wasp, 2 dead bees, a bird's nest (?), and around 20 years worth of grime. 3 days of cleanup and painting, and its much better now

Right. That was the expected outcome on paper. When I tested it, I couldn't notice a difference discernible enough to change something. Maybe you're a much better player than me and you'd notice a huge change. Your shaft would end up different than mine and that's awesome. Cue making doesn't have to be homogeneous.

I don't think millimeters of ferrule difference matter. After a couple of racks, you've subconsciously adjusted to the tiny nuance between each variation. I didn't miss that last shot because my Juma ferrule weighed .0002 more than it should. I missed because I was distracted by the pretty girl two tables over, or my stroke was 1/2 tip off center, or I kneejerk corrected at the end of my stroke, my shape wasn't optimal from the last pocketed ball, that one rail is dead when will they fix it, the felt isn't taken care of in this shitty place, these pockets are too small, my hands are sweaty, they pulled this simonis too tight. I've been playing pool for 3 decades with some really talented pool players and these are the reasons people lose control of the table.

Maybe I should call my shafts "LD ish". I want them to have LD characteristics. But not at the expense of sound, vibration, feel, etc... If that means my shaft will have 1/20th more deflection, I'm 100% okay with this. Squirt is something every player subconsciously accounts for anyway, to what degree is determined by his shaft, but we all do it.

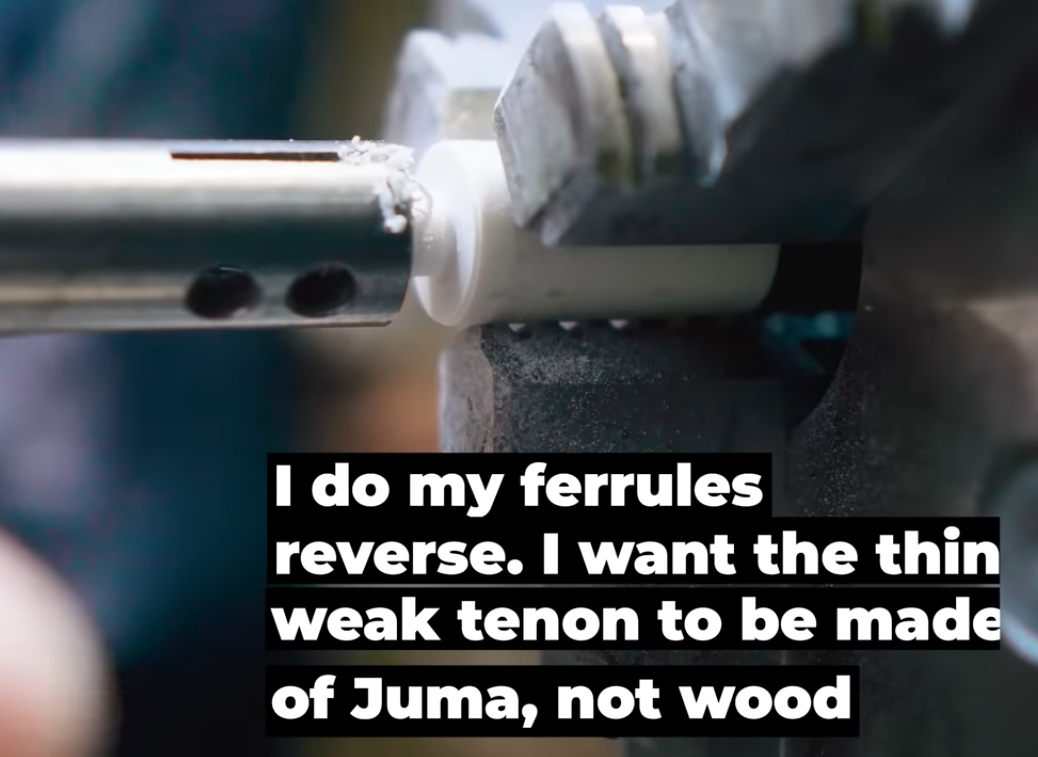

Yea, the shaft in question is ideal between 12 and 12.5. I think I'd change the taper and ferrule if I ever had to make a 13mm variation. I have a player who loves this shaft at 11.75 but that's just too thin for me. And I love that you went out and made it so you could see for yourself. Some of Mezz’s shafts several years ago used this same concept and their hole is tiny and deep. If I remember correctly it was over 5 inches deep and thinner than 1/4. Their ferrules aren’t Juma however.

Nice pics Joey, I'm sure they play great. It's personal preference. I used to do ferrules that way. I felt like they were just...shafts. Not terrible, not mindblowing, something in the middle. Good, solid, reliable. But I iterate on the butt, why not on the shaft?

View attachment 691046

My current ferrule implementation is a more traditional threaded (not reversed) variation (pic above). Form follows function... The ferrule made more sense this way because I changed how I core out the end.

I can also guess from these pics that I prefer denser shaft wood and more grain lines than Joey. Dunno. I try to hit 3.5oz+...although there doesn't seem to be any correlation between wood density and not warping, but I do like the weight more, I like the visual (pretty!), and I think they sound better. Personal preference. Vibration changes also.

View attachment 691047

I damn near crushed my fingers removing this Clausing's 8" chuck so I'm off to make a cradle.