TATE said:We went full circle and were right back to the beginning...

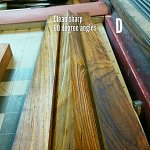

My humble suggestion.....

how about full-splice and not full-splice ???

All kidding aside, this is a very interesting thread/topic. My experience is that there is a lot of confusion/misinformation out there amongst the buying public regarding this kind of terminology.