Enigmaticul

Banned

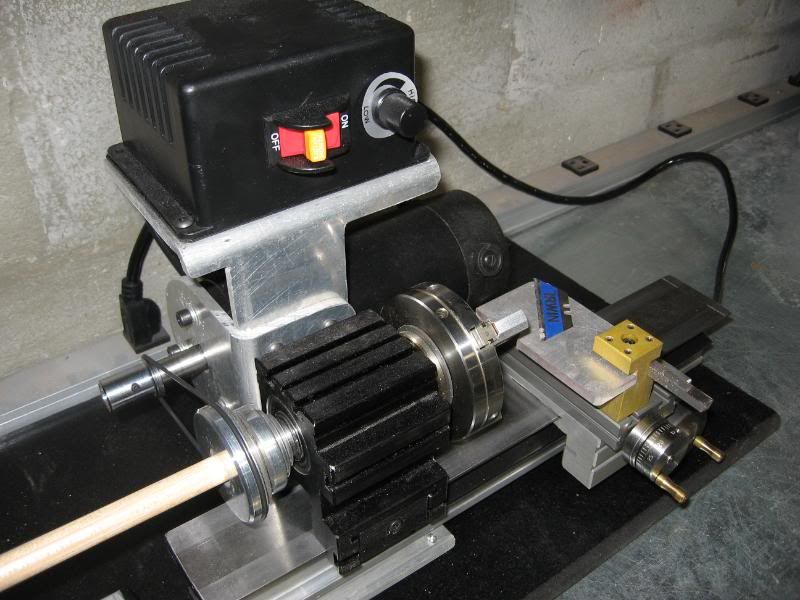

So I was about to start the design of the bracket for the penn state motor and I just realized that the spindle is assembled the other way!!!!!!

I don't know if taig changed the design or this was just assembled wrong??

The last head stock it had on my first lathe was the other way.

My issues come from the fact that the U channel to screw in the mount is facing me. The U channel on the other side has week walls.

This is the week channel

The stronger channel that I would of liked to be on the other side.

I don't know if taig changed the design or this was just assembled wrong??

The last head stock it had on my first lathe was the other way.

My issues come from the fact that the U channel to screw in the mount is facing me. The U channel on the other side has week walls.

This is the week channel

The stronger channel that I would of liked to be on the other side.