You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

uniloc QR stuck

- Thread starter pw98

- Start date

The thread has been moved to the ATCM sub-forum.I have a unilock QR that is stuck. I cant get it undone. I have nobody here to help either. How do i unstick it? Do i have to put it in the car assembled and get someone at the pool hall to help me?

Welcome to the wonderful world of the Unilock quick release. They do one of three things they work perfect, or they loosen as you shoot, or they lock up. In reference to your issue, grab the butt in your non-dominant hand, and about 12 in up from the joint on the shaft slap the stick into your hand so the shaft vibrates like a tuning fork and very quickly after that grab the joint and try to twist it to break it free. Sometimes the vibration will be enough to break it free may take a few tries to get it right. If that doesn't work after multiple tries you may have to grab another person and one grab the shaft the other the butt and try to unscrew it that way but you may actually break the bond that holds the insert in and then you will need a q repair guy. If the vibration method does work before you ever put it back together again take a Q-tip with some denatured alcohol or regular rubbing alcohol and clean the inside of the joint insert very well, keep rubbing one in there until it is not come out black. Also clean up the pin too. I always tell my customers to regularly clean the insert and pin at least once a month to keep things working well....DO NOT USE ANY LUBE!!!! If you do, it will only make thins worst down the road, just keep it clean

dendweller

Well-known member

I've resorted to strap wrenches when I've gotten a weight tap too deep and it wouldn't come loose. That might just pull out you insert though.I have a unilock QR that is stuck. I cant get it undone. I have nobody here to help either. How do i unstick it? Do i have to put it in the car assembled and get someone at the pool hall to help me?

DeeDeeCues

Well-known member

Due to the shape of the threads, the dissimilar metals, and the low thread count, you are likely experiencing galling in the threads.

This is an example of why gimmicky bastard threads should be avoided. Nobody working in the cue works is smart enough to create a better thread that the standard 60deg. v-threads that have been used for a couple hundred years.

This is an example of why gimmicky bastard threads should be avoided. Nobody working in the cue works is smart enough to create a better thread that the standard 60deg. v-threads that have been used for a couple hundred years.

I have never had a problem with my 14 year old Lucasi unilock cue.

Once or twice a year I clean the threads and insert with a Q tip dipped in alcohol.

Once or twice a year I clean the threads and insert with a Q tip dipped in alcohol.

I get them from time to time and I have seen inserts pulled out, pins bent, forearms damaged and shafts split due to people trying to fix it themselves..

Turn the cue upside down, use as little WD40 as possible and with rubber gloves on pull the cue straight apart. Clean out any WD40 left, then use Q-tips with denatured alcohol to clean the insert and pin, take care to not leave any part of the Q-tip or paper down in between the pilot recess and threads, blow everything clean with compressed air.

All cues should come with a manual on how to care for the cue, especially Uni-Loc pin cues, the tight tolerances on that pin need regular maintenance.

Turn the cue upside down, use as little WD40 as possible and with rubber gloves on pull the cue straight apart. Clean out any WD40 left, then use Q-tips with denatured alcohol to clean the insert and pin, take care to not leave any part of the Q-tip or paper down in between the pilot recess and threads, blow everything clean with compressed air.

All cues should come with a manual on how to care for the cue, especially Uni-Loc pin cues, the tight tolerances on that pin need regular maintenance.

Last edited:

DeeDeeCues

Well-known member

I get them from time to time and I have seen inserts pulled out, pins bent, forearms damaged and shafts split due to people trying to fix it themselves..

Turn the cue upside down, use as little WD40 as possible and with rubber gloves on pull the cue straight apart. Clean out any WD40 left, then use Q-tips with denatured alcohol to clean the insert and pin, take care to not leave and part of the Q-tip or paper down in between the pilot recess and threads, blow everything clean with compressed air.

All cues should come with a manual on how to care for the cue, especially Uni-Loc pin cues, the tight tolerances on that pin need regular maintenance.

If a mechanical joint that gets used a few hundred times per year in a clean environment needs a maintenance manual, it is an abject failure.

If you get lucky doing what Dave and Kim suggested. Check for burrs on both pieces.

Polish both if possible, takes a minute. The problems start at the beginning. Tumbler polishing really isn't that good. Polish them yourself and be done with the future problem.

Do not polish the part that gets glued in. Duhhhh!

Polish both if possible, takes a minute. The problems start at the beginning. Tumbler polishing really isn't that good. Polish them yourself and be done with the future problem.

Do not polish the part that gets glued in. Duhhhh!

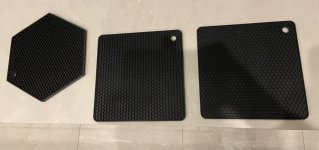

Attachments

I had such a cue come to me a few months ago. It just needed some very strong hand to undo the assembly. It just needed cleaning and it was chalk dust that caused it to be stuck together. After a serious clean and a de burr of the thread and the pin, all was good. I suggested they put the joint protectors on the cue to avoid such things, and to have clean hand when putting the cue together to avoid any chalk dust on the joint.

Or use bottle top grabbers/openers from Kitchen/kitchen supplyI've resorted to strap wrenches when I've gotten a weight tap too deep and it wouldn't come loose. That might just pull out you insert though.

If proper steps or a Cue mechanic was available to you. Your problem would have been solved with no more issues.I had two lock up on me in one year (Predators). Sold all my unilocs and will never buy another one.

I see your point, but in my experience a pool hall is not a clean environment, some of the stuff I repair looks like it's been used at the front in Bakhmut..If a mechanical joint that gets used a few hundred times per year in a clean environment needs a maintenance manual, it is an abject failure.

DeeDeeCues

Well-known member

I see your point, but in my experience a pool hall is not a clean environment, some of the stuff I repair looks like it's been used at the front in Bakhmut..

Clean is definitely a relative term, but my point is that there are screws that are used more often on construction, fabrication, and mining equipment that don't fail or seize.

Anything is possible but in most cases. Slim chance Slim. Usually the smooth shank of the pilot that gets frozen in the insert. This is the worst case after two guys tried so hard. They screwed the pooch. Usually past the threads as you see.Is it possible that it is cross threaded

Attachments

it is almost Impossible to cross thread and have it seat properly on the joint face.Is it possible that it is cross threaded