For the LAST time: the ferrule doesn't have anything to do with how much spin you can/can't get. How far from center you can strike the CB, WITHOUT miscuing, is what determines that. NOT the damn ferrule.What is the hit like and does it spin the ball better than other materials?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What so great about Westinghouse Micarta?

- Thread starter Belford

- Start date

Ok you convinced me. I will be the Guinee pig and try it. I will get one put on and report back here next week. What tip should I pair with it?For the LAST time: the ferrule doesn't have anything to do with how much spin you can/can't get. How far from center you can strike the CB, WITHOUT miscuing, is what determines that. NOT the damn ferrule.

I used to have a lot of respect for you, Kelly. But that was before I figured out you don't know how to read.Cue Components "Westinghouse" ferrules are not Westinghouse. They are most likely newer Chinese micarta. They don't look like Westinghouse and certainly don't machine like any Westinghouse micarta.

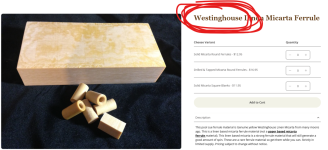

Westinghouse, and later International Paper micarta provide a firm hit and are easy to clean chalk dust off of unlike most other ferrule materials.

Attachments

Everyone, well most everyone i guess, on AZ knows that a ferrule won't increase/decrease spin. Don't need your 'test' data believe me. I've owned cues with EVERY ferrule you can name and NONE had any effect on how much spin i got. How they FEEL is a different story but not spin.Ok you convinced me. I will be the Guinee pig and try it. I will get one put on and report back here next week. What tip should I pair with it?

The jury is still out as to whether they spin the ball better than all other ferrule materials. But let's do a mind exercise and imagine they do. Assuming one of these magic ferrules provides 10% more spin than any other ferrule material, imagine how much spin you could get if you used two of them! Hell, let's make and entire shaft... No, wait... AN ENTIRE CUE out of Westinghouse Paper Micarta!!! Holy shit... This might just be our Oppenheimer moment where we destroy the earth with too much spin on a cue ball. Maybe that's where black holes actually come from. Hold on, guys. I'm gonna call Neil deGrasse Tyson and talk to him about it.What is the hit like and does it spin the ball better than other materials?

Who died and made you the King of Spin? Maybe you just have a bad stroke. Personally, I had to stop using cues with WM ferrules in tournaments because the cue ball was never done spinning by the time my shot clock ran out.Everyone, well most everyone i guess, on AZ knows that a ferrule won't increase/decrease spin. Don't need your 'test' data believe me. I've owned cues with EVERY ferrule you can name and NONE had any effect on how much spin i got. How they FEEL is a different story but not spin.

All joking aside, I cannot for the life of me understand peoples' obsession with ferrules and tips and getting as much spin as humanly possible. I'm not saying there's inherently anything wrong with it. It's just not what I'd worry about unless I was the best player in the world and trying to put on exhibitions of some sort.

Fire retardant.What are the advantages of Westinghouse Micarta?

I've never seen a cue with a Westinghouse Micarta ferrule catch fire. So you're definitely onto something.Fire retardant.

JacobyToby

Registered

I am interested in the results. I would use a Tiger Onyx or a pooldawg8 milkdud with the Micarta.Ok you convinced me. I will be the Guinee pig and try it. I will get one put on and report back here next week. What tip should I pair with it?

lol, absolutely.Fire retardant.

For those interested here is a great page that provides a lot of information about Micarta (chopdoc likely knows most of this already). Spoiler alert: not a mention of pool cue ferrules (but the picture of turning a large chunk on a lathe may be familiar to cue makers)

Westinghouse Micarta — Kimberlin Co.

Developed in 1910 by Westinghouse Electric Corporation as an industrial thermo-set laminate for electrical insulation, Micarta is known for being "The Steel of the Plastic Industry".

Dave <-- not a big fan of cutting plastics but was working with HDPE the other day

Cue makers have always found, experimented, with products/materials from other industries for their cues. Some work better than others. Some would argue don’t work well at all. There are more choices now than ever including adhesives. Cue making is such a small industry that most of the products used were not intended for cue making. Even the old schooler’s equipment and tooling were not intended for cue making. In the past unless you had a stake in selling products to other cue makers you kept your discoveries that worked close hold… as much information that is available & shared I believe this is still prevalent.lol, absolutely.

Spoiler alert: not a mention of pool cue ferrules (but the picture of turning a large chunk on a lathe may be familiar to cue makers)

Last edited:

My post was intended to help folks understand a material. I find many have no concept of materials, their properties, their history etc., but then I am an engineer who took classes in those subjects and have worked with many new and old things over the decades.Cue makers have always found, experimented, with products/materials from other industries for their cues. Some work better than others. Some would argue don’t work well at all. There are more choices now than ever including adhesives. Cue making is such a small industry that most of the products used were not intended for cue making. Even the old schooler’s equipment and tooling were not intended for cue making. In the past unless you had a stake in selling products to other cue makers you kept your discoveries that worked close hold.

Dave <-- once made a cue ferrule from a bantam jack sleeve

My post was intended to augment your statement and by no means was it meant to denigrate.My post was intended to help folks understand a material. I find many have no concept of materials, their properties, their history etc., but then I am an engineer who took classes in those subjects and have worked with many new and old things over the decades.

Dave <-- once made a cue ferrule from a bantam jack sleeve

lol, absolutely.

For those interested here is a great page that provides a lot of information about Micarta (chopdoc likely knows most of this already). Spoiler alert: not a mention of pool cue ferrules (but the picture of turning a large chunk on a lathe may be familiar to cue makers)

Westinghouse Micarta — Kimberlin Co.

Developed in 1910 by Westinghouse Electric Corporation as an industrial thermo-set laminate for electrical insulation, Micarta is known for being "The Steel of the Plastic Industry".www.erickimberlin.com

Dave <-- not a big fan of cutting plastics but was working with HDPE the other day

Well you could look up the specs here I guess.

Wesitnghouse Micarta fire retardant asbestos specs

Or study it here.

Military Text

Maybe get an old catalog.

Asbestos Micarta Catalog

If you think a ferrule is expensive, look at the price of an old catalog! LOL!

That's gonna be one hell of a shaft collar. Thank you for sharing this. It's always fun for me to see the history of some of the more esoteric materials that are used in cues. And I realize cue makers aren't the only ones looking for this stuff - I'm pretty sure knife makers love it too. Although I'm not sure how much they do or don't care about whether it's the old Westinghouse paper stuff versus the newer versions.lol, absolutely.

For those interested here is a great page that provides a lot of information about Micarta (chopdoc likely knows most of this already). Spoiler alert: not a mention of pool cue ferrules (but the picture of turning a large chunk on a lathe may be familiar to cue makers)

Westinghouse Micarta — Kimberlin Co.

Developed in 1910 by Westinghouse Electric Corporation as an industrial thermo-set laminate for electrical insulation, Micarta is known for being "The Steel of the Plastic Industry".www.erickimberlin.com

Dave <-- not a big fan of cutting plastics but was working with HDPE the other day

boogieman

It don't mean a thing if it ain't got that ping.

It's a fairly hard hit. Not like phenolic hard but maybe something like ivory. I've only hit with ivory twice and it has a different feel to it. Hard to explain. It's not soft feeling like a meucci if that makes sense.What is the hit like and does it spin the ball better than other materials?

As far as I know a ferrule does nothing for spin. That's all about stroke. I like how this ferrule looks, feels, machines/polishes, and resists chalk. It's a really good ferrule, I doubt you'll find any that play better for $3.25. It's a quality material.

Micarta is a term for a composite material, often paper, linen, canvas or fiberglass set in phenolic resin.

Micarta was a brand of micarta made by the Westinghouse company and the production goes back almost to days of Tesla and Edison.

This was pre modern plastics and it was a huge industry.

If you want to read about the history of "The steel of the plastic industry" you can do so here:

Westinghouse micarta

Micarta was a brand of micarta made by the Westinghouse company and the production goes back almost to days of Tesla and Edison.

This was pre modern plastics and it was a huge industry.

If you want to read about the history of "The steel of the plastic industry" you can do so here:

Westinghouse micarta

Isn't it funny how it can be kind of difficult to explain the "hit" of a cue or how changing a cue's components can change that hit?It's a fairly hard hit. Not like phenolic hard but maybe something like ivory. I've only hit with ivory twice and it has a different feel to it. Hard to explain. It's not soft feeling like a meucci if that makes sense.

As far as I know a ferrule does nothing for spin. That's all about stroke. I like how this ferrule looks, feels, machines/polishes, and resists chalk. It's a really good ferrule, I doubt you'll find any that play better for $3.25. It's a quality material.

As far as ivory goes, I've had cues with ivory ferrules and they all hit just fine. The funny thing is, they all hit noticeably differently. I realize that's a function of the cues' other geometries and components. But I think it's important to note to anyone new to the game that you can't just slap an ivory ferrule on a garbage cue and expect it to "hit a ton."

The closest thing I've had to a true apples to apples comparison was a Samsara cue I ordered from them back around 2000. It can with LBM ferrules and Sumo tips. The cue played great. But holy hell it had the craziest "PING!" sound I've every experienced in cue. I had the tip changed to a Moori medium and that dropped the noise level down a noticeable amount. But it was very much still there. So then I had the ferrule on one shafts changed to ivory and another Moori medium put on by Joe B. down at The Derby. After that, there was no more "PING!" but the cue still felt basically the same to play with. It might have had a very slightly softer hit but I no longer felt like I was eventually going to get hearing damage by using it.

Thanks, that link was provided already. Really great that that is maintained. I am from Pittsburgh, so Westinghouse was a big deal to me growing up. I knew one of the engineers that worked on the designs for the nuclear reactors for the Nautilus.Micarta is a term for a composite material, often paper, linen, canvas or fiberglass set in phenolic resin.

Micarta was a brand of micarta made by the Westinghouse company and the production goes back almost to days of Tesla and Edison.

This was pre modern plastics and it was a huge industry.

If you want to read about the history of "The steel of the plastic industry" you can do so here:

Westinghouse micarta

Maybe important in this conversation is the fact that we are talking specifically about the asbestos product. Obviously asbestos is a health hazard, it causes asbestosis, a pneumoconiosis. Pneumoconiosis in general is the most common occupational lung disease. But it's also a direct cause of mesothelioma and commonly associated with bronchogenic carcinoma.

Probably the cue makers that are formally trained machinists know the risks well because of their training and workplace precautions, but perhaps those cue makers that are more self taught are less aware. I am just guessing.

The issue isn't just asbestos. Wood dust, cotton dust (from canvas phenolics for example), as well as ivory dust can all cause pneumoconiosis.

We occasionally see it mentioned that Cocobolo dust is very irritating, and most have probably heard about the dangers of asbestos, but I think fewer in the general public are aware of, or take seriously, other particulate risks. There are numerous causes of pneumoconiosis. Wood turners would be at particular risk, especially cue makers since they work with a variety of materials.

Many see OSHA as a malicious agency. "PPE" has become a political hot button term. Politics, controversy, and kidding aside, if you are working with any of this stuff, take reasonable precautions. It's not "common sense", if it was a lot of pulmonary physicians would be bored. I think we all want our cue makers alive an well.

Last edited:

It's an amazing piece of industrial history and you are right Micarta and many other materials can be pretty toxic and PPE is a must if you don't want to slowly kill yourself..Thanks, that link was provided already. Really great that that is maintained. I am from Pittsburgh, so Westinghouse was a big deal to me growing up. I knew one of the engineers that worked on the designs for the nuclear reactors for the Nautilus.

Maybe important in this conversation is the fact that we are talking specifically about the asbestos product. Obviously asbestos is a health hazard, it causes asbestosis, a pneumoconiosis. Pneumoconiosis in general is the most common occupational lung disease. But it's also a direct cause of mesothelioma and commonly associated with bronchogenic carcinoma.

Probably the cue makers that are formally trained machinists know the risks well because of their training and workplace precautions, but perhaps those cue makers that are more self taught are less aware. I am just guessing.

The issue isn't just asbestos. Wood dust, cotton dust (from canvas phenolics for example), as well as ivory dust can all cause pneumoconiosis.

We occasionally see it mentioned that Cocobolo dust is very irritating, and most have probably heard about the dangers of asbestos, but I think fewer in the general public are aware of, or take seriously, other particulate risks. There are numerous causes of pneumoconiosis. Wood turners would be at particular risk, especially cue makers since they work with a variety of materials.

Many see OSHA as a malicious agency. "PPE" has become a political hot button term. Politics, controversy, and kidding aside, if you are working with any of this stuff, take reasonable precautions. It's not "common sense", if it was a lot of pulmonary physicians would be bored. I think we all want out cue makers alive an well.

Products made especially for the cue industry is a relatively new phenomenon. That's why you see the use of Micarta, canvas and phenolic, linen thread and 3/8-10 screws, all things taken from other industries and incorporated into cue making