Hey Guys,

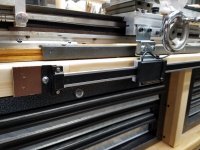

In trying to cut trim rings to consistent sizes, I use a set of calipers and hold it with one hand between the tool post and one of the chuck jaws while moving the cross slide with the other hand. It's tedious and janky to say the least.

Anyone else that's using a Mid-America/Unique style lathe come up with a better way?

Thanks much,

Rob

In trying to cut trim rings to consistent sizes, I use a set of calipers and hold it with one hand between the tool post and one of the chuck jaws while moving the cross slide with the other hand. It's tedious and janky to say the least.

Anyone else that's using a Mid-America/Unique style lathe come up with a better way?

Thanks much,

Rob