I jsut want to interject a little technical information into the conversation.

"Tooling" in leather work ususally is applied to mean decoration that was stamped or carved using a manual tools. Tooling is generally thought of as "hand-tooling" for this reason. However in a strict sense tooling applies to any type of decoration on leather where the leather was molded or shaped by any means. This includes stamping and embossing done with die presses and roller presses. One tooler even uses a pneumatic chisel that he modifed to insert his manual tools and make them into power tools.

Tooling is generally broken down into the following categories;

Stamping: Impressing the leather by means of a single stamp which is repeated to form a pattern. Done well this looks highly professional and flawless. Done wrong it looks sloppy. The tooler can adjust the depth by altering the force of the hit on the stamp, and alter the look by changing the angle or direction of the stamp.

Embossing: Impressing the leather by means of a mechanical press. In general the stamps used can only be applied straight down and the force is much greater than manual stamping. Thus such work often has the "factory" or standard look to it without much character. There are embossing artists however who use mechanical presses to achieve a lot of character and uniqueness when using this method.

(Note: Embossing also refers to the reverse sculpting of leather by wet forming from the back to create 3-d figures and shapes. I don't know why the word is used for this but it is.)

Carving: Carving is the art of making decorative cuts in the leather and then stamping and molding around and under those cuts for effect. The tooler has a lot of freedom to shape the character by varying the depth and width of the cuts.

So, for the purpose of this thread it would serve to have everyone understand that the work which was done on their case may not have been done as they think it was done regardless of who did it.

Mrs. Van Horn had help in her shop. I can tell you that in any shop the help almost always aspires to be the artist. So it would have been only natural for Mrs. Van Horn to have allowed others to do some of the tooling depending on the project for both practical reasons.

It would have also been natural to consider ways to produce more efficiently when you are essentially a production shop. Now I am not going to sit here and say definititively that Mrs. Van Horn or Jay Flowers ever set up any "production" methods to decorate the cases but it would have been a clever and practical thing to had they done so. I can tell you that it's very easy to set up a die stamp that looks just like a line of hand tooled stamps.

If you go to Tandy Leather's web site you can find the type of presses and equipment in use by leather workers and cue case makers around the world. Whenever you see a case which has straight lines cut into it then it's likely that those are guidelines used for the mechanical stamping process or lines that were cut into the leather by the stamping wheel or die itself. With hand tooling (hand stamping) you will often see a faint line that was scribed onto the leather as a guide and the tooling will be more or less on that line.

I hope that more people come forward with their stories of J.EF/NVH - Jay Flowers/Nora Van Horn cases.

I think it would be cool to see if we can't get people to connect dates to their cases so that we can start to piece together a timeline which showcases the birth and evolution of the cases.

Here is the thing in my mind - the case made with individual tubes was a game changer. After Jay Flowers brought these cases to the attentinon of the pool world is when we started to see cases with rigid individual compartments for the cues. Meucci experimented with foam to create what eventually became the Porper cases. Dennis Swift came along, Whitten, Justis, Instroke, and others building on the same principle of putting leather around a collection of tubes, all inspired by the Flowers/Van Horn cases.

As to the decoration - well like I said let's build a library and attach dates to pictures and try to nail down who did what and how.

Thank you Chris for doing the leg work on this and helping to preserve an accurate history of this part of the pool world.

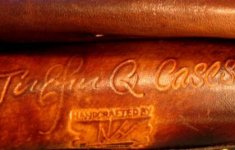

This is the only Jay Flowers (no NVH logo) case I own - I was told that it was acquired from Jay more than 20 years ago. It is similar in build and decoration to the one I got from Andi Sattler in Germany around 1991 which I took completely apart.

This one does not have the NVH stamp nor the J.EF Q Cases logo.