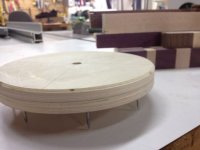

Glen has posted pictures of GC carpet feet before. These are designed to not damage the carpet from the weight of the table. This is especially important to me, as I'm installing the table in an apartment, and I don't want to be charged for damaging the carpet.

I decided to build my own for a GC4 I have coming very soon. I thought you guys would enjoy the pictures. I'm not a mechanic, just a guy with a woodworking background...

I measured the circumference with a length of wire and a magic marker on an existing GC4 table at the local pool hall.

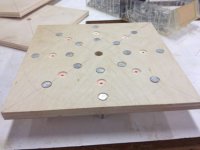

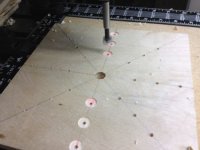

Qty 8: 1/2" nominal plywood cut to oversize squares

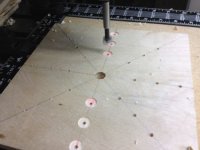

1/2" hole drilled in center for future work indexing purposes.

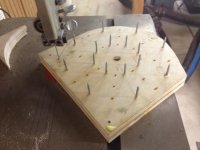

1/2" pin aligns all work pieces. Nail holes gang drilled through all 4 boards.

Counterbore for nail heads made with forstner bit

.... Continued next post....

I decided to build my own for a GC4 I have coming very soon. I thought you guys would enjoy the pictures. I'm not a mechanic, just a guy with a woodworking background...

I measured the circumference with a length of wire and a magic marker on an existing GC4 table at the local pool hall.

Qty 8: 1/2" nominal plywood cut to oversize squares

1/2" hole drilled in center for future work indexing purposes.

1/2" pin aligns all work pieces. Nail holes gang drilled through all 4 boards.

Counterbore for nail heads made with forstner bit

.... Continued next post....

Last edited: