This has been a great thread considering I am looking to do the same thing. I just have a couple of questions. Steve had mentioned not using round rails and I have come across a deal on 1" supported round rails with 6" long beatings I was wanting to use on my X axis. Are they that much of a problem to use? I know the UN supported rails will flex but what do you guys think about these? Also about what oz motor are most of you using on your machines?

Thanks for any help,

Donnie

Donnie

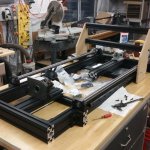

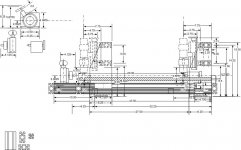

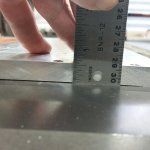

I really do prefer the square rails as opposed to round rails. Supported rails are certainly much better than round, and you can build an excellent machine with them. But, if I have a choice I will choose the square rails. The are much shorter in height so the machine can be much more compact. They are stronger, will support more load, and will last longer than round rails. They are readily available on ebay for pretty much the same money as the round ones, so It's kind of a no brainer.

On to motors. Ounces per inch is a measurement for holding torque. Most of the time, a motor with a big holding torque will have a high impedance and won't like to spin very fast. We don't really need to go fast building cues, but I promise you that if you build a machine that can only move at 20 inches a minute, you will regret it. You will end up trying to move it too fast and losing steps.

In a properly setup and run stepper system, you should pretty much never miss steps.

I strongly recommend Gecko drives and motors.

The G540 is a small 4 axis motherboard and drives combination that will handle 50 volts and 3.5 amps. I have at least a half dozen of them in my shop right now, and am adding 4 more.

The G203v drives are absolutely fantastic. They will handle 70 volts and 7 amps so they will drive strong fast motors. I have 2 of these on my inlay machines and they run perfectly. I will be adding another inlay pocket machine soon and will use another G203v setup. The drives are individual and require a motherboard and all the related hardware so they are more difficult to setup. But they are good.

I use the same motor for either drive, the 400 ounce motors from Gecko. They're cheap, have excellent linearity, and work very well with either drive. They are rated at about 5 amps, but still work well on only 3.5 amps with the G540.

I recommend reading all the support information on their website. Here's a link to the support page:

http://www.geckodrive.com/support.html

You can't help but learn a lot about CNC systems by reading this. I've been doing it for over 8 years, and I still go back and read parts again. Especially when I'm trying to figure something out.

Well, I hope that helps

Shoot Straight!

.