You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ISO WICO points

- Thread starter ratcues

- Start date

Have you tried taking two pieces at a right angle and welding them together with solvent? I have a little experience with ABS and other plastics. A simple cement (though you can also try something like Weldon) can be made by dissolving some ABS bits in acetone. You may well be able to get a "seamless" joint by simply melting the two pieces together with solvent.

Anyhow, it's something to try on a little bit of scrap, and I've had pretty good luck with it.

Anyhow, it's something to try on a little bit of scrap, and I've had pretty good luck with it.

Looks like a good start. Are you pressing between two pieces with sharp inner & outer angles?

My jig isn't perfect but this was a good proof of concept.

Have you tried taking two pieces at a right angle and welding them together with solvent? I have a little experience with ABS and other plastics. A simple cement (though you can also try something like Weldon) can be made by dissolving some ABS bits in acetone. You may well be able to get a "seamless" joint by simply melting the two pieces together with solvent.

Anyhow, it's something to try on a little bit of scrap, and I've had pretty good luck with it.

I have taken that into consideration but I really want to do this as an angled, solid piece. That was the whole point of the WICO points was to have no visible seam. I've only got one shot once I glue them into the forearm. It needs to be right.

Obviously a lot of effort going into this to do it "right".

I appreciate you sharing it with us.

I'm getting closer...

I'm getting closer...

If you were closer I'd loan you my finger brake kit, it uses a vice for pressure. They might do the trick and are overall cool

Something like this :

https://www.amazon.com/Grizzly-H3244-5-Inch-Vise-Brake/dp/B0000DD4UV

Dave

I have taken that into consideration but I really want to do this as an angled, solid piece. That was the whole point of the WICO points was to have no visible seam. I've only got one shot once I glue them into the forearm. It needs to be right.

Gotcha. Just want to say that if you do it right, you actually do end up with a seamless joint because the solvent actually melts the pieces into each other, but I can see not wanting to take a chance given the consequences if something goes wrong, especially with a new technique.

Might be worth just trying once on scrap just for your own curiosity, though.

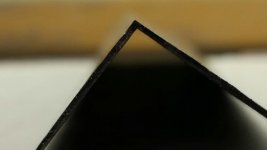

First attempt. Not bad but the corners should be sharper.

My first shot at one piece wood veneers looked like that.. Didn't work out to good even with pressure. I hope you pull it off.

My suggestion is to make a right angle mold using two metal plates. By making a 90 degree sharp mold set. Heat the material up so its pliable, or heat the plates, and apply pressure till the material molds itself in the gap of the two plates, removing the bent radius.

You might get away with doing this very small and only trying to remove the radius in the corner. But you may pull / stretch the corner while squaring it off, giving you uneven thickness in the veneer.

JV

You might get away with doing this very small and only trying to remove the radius in the corner. But you may pull / stretch the corner while squaring it off, giving you uneven thickness in the veneer.

JV

My suggestion is to make a right angle mold using two metal plates. By making a 90 degree sharp mold set. Heat the material up so its pliable, or heat the plates, and apply pressure till the material molds itself in the gap of the two plates, removing the bent radius.

You might get away with doing this very small and only trying to remove the radius in the corner. But you may pull / stretch the corner while squaring it off, giving you uneven thickness in the veneer.

JV

I was going to suggest exactly that, and didn't for exactly the reason you mentioned. The thing is that no matter what you do, you need to shrink material on the inside of the bend and stretch it on the outside. A sheet metal guy is going to know what I'm talking about. It's really pretty tough to bend anything into a true 90 degree corner without a significant radius. Even a piece of paper with a sharp crease usually has a visible radius.

Really following this very closely to see what the final solution and outcome is. You cue makers are a pretty clever bunch!

Looking much better!

Have you given any thought to possibly starting with a thicker piece, bending it, and then sharping the corners by either sanding or machining (maybe with a router table and a couple of jigs)?

Have you given any thought to possibly starting with a thicker piece, bending it, and then sharping the corners by either sanding or machining (maybe with a router table and a couple of jigs)?

I'm getting closer

Outside looking good. Inside...still tricky. I'm pullin for ya

Outside looking good. Inside...still tricky. I'm pullin for ya

Wowee...that's close! Are you heating the whole think up and letting it all flow a little, or just locally at the bend, if you don't mind answering?

Wowee...that's close! Are you heating the whole think up and letting it all flow a little, or just locally at the bend, if you don't mind answering?

A little of everything. If I get it too hot, I get bubbles in the material. I add heat to the angle aluminum, then to the plastic, put them into the press and heat the sandwich. I'm doing it all by feel. I've also been adjusting the PSI. It is quite the dance...

Question

What material will you use for the white veneer??????

Thanks

Kevin

I've checked with every manufacturer that has ever used them or even made cues in the same era. I may have to build them from scratch.

What material will you use for the white veneer??????

Thanks

Kevin