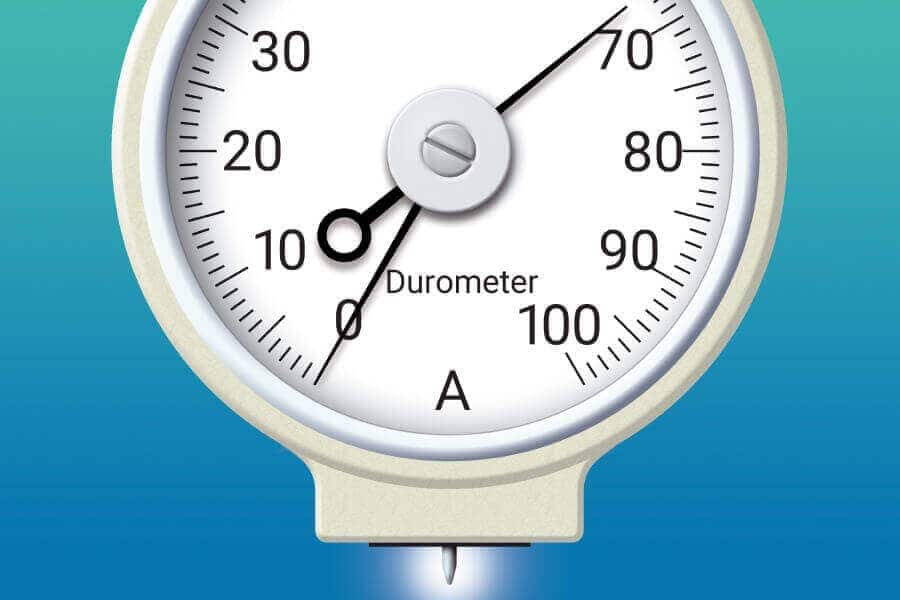

Shore is a reliable unit-less measurement to compare relative hardnesses to each other. It’s accurate and reliable. The different scales for Shore are all reliable and is globally accepted across many industries manufacturing damn near everything. Your morning cereal has a Shore rating of some sort-not A or D.

So a couple years ago I fell into a biz-acrylics that was practice for bigger better biz ideas. But I needed to learn a lot, I’m still learning. Part of this ended up being measuring the hardness of the materials I’m having made.

That opened up a new chapter in my life going down a rabbit hole I knew very little about. Sure I had 9 semesters of Chem before they threw me out of school, science and measurements aren’t new to me. But Shore hardness and the related measurement equipment was new.

I own that equipment now, nothing $800 wouldn’t solve. I got good stuff-ofc there’s better and maybe someday.

Anyways back to tips. I had my Shore D durometer and after a few days, it occurred to me to try it on a tip. It’s some layered Japanese tip. It came in at 54. Which was interesting. I thought it would be too soft and D was the wrong idea. I only tried the one tip(new not on a cue).

For a couple days I thought I had reinvented the wheel until I gave it more thought. No chance I’m the first guy to think of this, there are way too many smart guys out there.

So I pondered more.

Here’s the problem I have with Shore testing tips. Yes it’s a great measurement for tips when they are new. And we can quantify the relative hardness between all new tips. Water Buffalo will be harder than Elk Masters and ofc Triangle tips will be perfect. We can all agree? lol What’s new? Don’t we always agree on everything on AZB?

So back to the problem. A tip is only new once. Until it’s installed. Then it becomes a used tip after the first shot and has a pretty short life(if you are playing enough pool).

What I’ve noticed is tips tend to get hard and glaze over. A scuffer takes care of the glaze easy enough. The problem I personally have experienced over the decades and a zillion tips is they tend to get harder with use. For me, maybe it’s how I hit the ball, chalk, what ever variables are in play-when I use layered tips they get harder and harder until they turn into rocks. Seems like the adhesive and leather layers kinda merge into a super hard substance. Or the dead opposite they un laminate and are ½” tall and spongy.

Ultra skins seem to be the best layered tip to solve that problem. But that’s another conversation

My point is as a tip is used it hardens up most of the time. After a few weeks they seem to hit a sweet spot for me and then wear out.

What would be interesting is to test a tip, install it and track how many hours of use it gets and retest it. For example every 30 hours of use or 50. Just a consistent number. After a few tips it would be interesting to see the graph on what’s happening with the hardness of that particular tip.

The hardness over the life span of a tip is what I’m getting at. I’d bet we would see some tips get considerably harder and see some stay closer to their “at new” measurement. Like a Triangle is likely to do(shameless unsponsored plug).

This is a fun topic for me. Quantifying organic materials is an almost impossible pursuit. But it’s sure fun to try. I’ve had this conversation with Tony at Black Boar many times. Metals are predictable and boring lol-so says the grand master.

Ok Sunday writing practice is over. I almost started this as a topic a few weeks ago. Glad I didn’t.

If I was still playing I’d do this test on my tips for a year or 2 as the results are super interesting. Problem is at the rate I’m playing I’d need about 4-5 years per tip. Wouldn’t be much data.

Fatboy