You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diamond wood and assumptions?

- Thread starter Michael Webb

- Start date

I know nothing about diamond wood

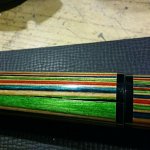

I do however make break cues using dymalux and spectraply. Dymalux is pressure impregnated throughout, the wood and very heavy. Spectraply is just glued together, and close to the weight of maple, maybe a bit heavier.

I use a 3/8 by 10 into wood threads. I have only made about 20 of these cues and as of yet none have split. No rings, no insert.

I really think the only way they will break is if you dig the tip into the cloth and leave your bridge hand on the table and raise your grip hand, it bends the cue right at the joint. I think this is the reason they break.

I might consider using a joint ring in the future.

I do however make break cues using dymalux and spectraply. Dymalux is pressure impregnated throughout, the wood and very heavy. Spectraply is just glued together, and close to the weight of maple, maybe a bit heavier.

I use a 3/8 by 10 into wood threads. I have only made about 20 of these cues and as of yet none have split. No rings, no insert.

I really think the only way they will break is if you dig the tip into the cloth and leave your bridge hand on the table and raise your grip hand, it bends the cue right at the joint. I think this is the reason they break.

I might consider using a joint ring in the future.

I do however make break cues using dymalux and spectraply. Dymalux is pressure impregnated throughout, the wood and very heavy. Spectraply is just glued together, and close to the weight of maple, maybe a bit heavier.

I use a 3/8 by 10 into wood threads. I have only made about 20 of these cues and as of yet none have split. No rings, no insert.

I really think the only way they will break is if you dig the tip into the cloth and leave your bridge hand on the table and raise your grip hand, it bends the cue right at the joint. I think this is the reason they break.

I might consider using a joint ring in the future.

This is exactly what I believe. I have a few friends that break in the 27-28ish MPH and both their follow thru goes right into the table....and both have broken a shaft I made right at the joint. Both had a phenolic insert, but no collar that encompassed any wood. There was a collar, installed on just the phenolic insert....was a bad idea on my part. Was trying for a more firm/solid hit, but with their style of breaking ...literally broke it. I now use a .5" phenolic collar on their break shafts and no insert, and have had no issues since.....lesson learned. To me, an insert, with no substantial collar of phenolic of at least .400" just acts like a wedge or lever to break apart the shaft at that point. A collar of 1/8" is just decoration, not anything to do with strengthening the joint

Just my thoughts from my experiences.

Dave

Sneakys

True sneakys with out joint rings will split like this, I have seen dozens of them. When I was playing in Kansas city in the 80's. I played with a sneaky as did many of my buddies. I never broke mine because I break straight. But most of the guys that bend cue on break will snap them like a spaghetti strand.

True sneakys with out joint rings will split like this, I have seen dozens of them. When I was playing in Kansas city in the 80's. I played with a sneaky as did many of my buddies. I never broke mine because I break straight. But most of the guys that bend cue on break will snap them like a spaghetti strand.

Ouch!

A simple solution might have been a T-shaped collar-insert.

Use phenolic rod, thread it 5/8 18, then leave 1/4 cap out for "collar".

Then again a simple .500 collar does the yab too.

Last edited:

True sneakys with out joint rings will split like this, I have seen dozens of them. When I was playing in Kansas city in the 80's. I played with a sneaky as did many of my buddies. I never broke mine because I break straight. But most of the guys that bend cue on break will snap them like a spaghetti strand.

Brass insert and no collar Scruggs sneakies have survived decades .

Brass insert and no collar Scruggs sneakies have survived decades .

That is because he used a brass insert. But I am guessing he had some failures also.

It would be really interesting to test out if someone has time and money to burn. I would guess 0.5in+ collar of various materials would protect the joint for sure, and the only way to protect against repeated bending (although the shaft needs a collar too).

For inserts, brass would probably beat phenolic handily IMO and better than no insert. Hardwood with same grain orientation no significant difference than without insert. Hardwood in different orientation vs brass? Brass or phenolic sleeved over hardwood? Fun mental experiments.

For inserts, brass would probably beat phenolic handily IMO and better than no insert. Hardwood with same grain orientation no significant difference than without insert. Hardwood in different orientation vs brass? Brass or phenolic sleeved over hardwood? Fun mental experiments.

It would be really interesting to test out if someone has time and money to burn. I would guess 0.5in+ collar of various materials would protect the joint for sure, and the only way to protect against repeated bending (although the shaft needs a collar too).

For inserts, brass would probably beat phenolic handily IMO and better than no insert. Hardwood with same grain orientation no significant difference than without insert. Hardwood in different orientation vs brass? Brass or phenolic sleeved over hardwood? Fun mental experiments.

Mental experiments create more questions.

Physical experimentation create experience and wisdom.

Mental experiments create more questions.

Physical experimentation create experience and wisdom.

All I got is my mind right now and some hand tools. Hard to get that experience as yet. As for wisdom, you can't answer a question if you never ask it. Takes both.

Sorry for presenting any kind of authority here on cue making. I have none. Have some woodworking and engineering experience, so that's where I'm coming from. When strengthening a joint via spline, for instance, you orient the grain differently or you're not strengthening a joint aside from increased gluing surface away from the end grain. As for engineering, it's not realistic to try and make things so reinforced they can't break. Better to understand where forces are coming from and wanting to be able to flex. For making an accurate CNC, for instance, you can either try and make it so rigid to eliminate flex and spend a lot of $$, or you can understand what is going to flex when force is applied and get things to flex together.

All I got is my mind right now and some hand tools. Hard to get that experience as yet. As for wisdom, you can't answer a question if you never ask it. Takes both.

Sorry for presenting any kind of authority here on cue making. I have none. Have some woodworking and engineering experience, so that's where I'm coming from. When strengthening a joint via spline, for instance, you orient the grain differently or you're not strengthening a joint aside from increased gluing surface away from the end grain. As for engineering, it's not realistic to try and make things so reinforced they can't break. Better to understand where forces are coming from and wanting to be able to flex. For making an accurate CNC, for instance, you can either try and make it so rigid to eliminate flex and spend a lot of $$, or you can understand what is going to flex when force is applied and get things to flex together.

Not judging your experience. I enjoy your post. I look forward to you getting equipment to support your thoughts.

Not judging your experience. I enjoy your post. I look forward to you getting equipment to support your thoughts.

Thanks! I know builders invest a ton in their craft and guard their wisdom because it needs to be earned else it won't be learned. Everyone who buys the fancy equipment imagining jumping into the biz seems to get burned and/or flame out. I hope to toe the line in that regard, though it's hard to contain the ideas, and I've learned a ton through the exchanges here.

Thanks! I know builders invest a ton in their craft and guard their wisdom because it needs to be earned else it won't be learned. Everyone who buys the fancy equipment imagining jumping into the biz seems to get burned and/or flame out. I hope to toe the line in that regard, though it's hard to contain the ideas, and I've learned a ton through the exchanges here.

Forums can be fun and discouraging if you don't take it for what it's worth. Basically a discussion. I pick and choose my battles, I try to help. But if it's something I don't want to share, I DON'T. Others are the same way. When people get rude, disrespectful and forget we take our jobs serious. We just stop playing. You could hear a mouse piss on a cotton ball. Lol

People really seem to like the dymondwood jump breaks, i think mostly because they think they are indestructible. I personally dont like the heavy shaft. Ive been using spectreply and putting maple in for the threads for the jump handle, and using a maple shaft , and havent seen a failure yet. I am thinking about trying phelonic. Have tried both a phelonic ring and no ring at the jb joint, always a 3/8 10 pin. Always interesting stuff coming out of Mr Webb. Great info mike

Joey, Dave, Michael, Desi, Kim, and Chris. I always enjoy reading your thoughts/posts on cuemaking, and thanks to each of you for taking time to make this place more interesting.

People really seem to like the dymondwood jump breaks, i think mostly because they think they are indestructible. I personally dont like the heavy shaft. Ive been using spectreply and putting maple in for the threads for the jump handle, and using a maple shaft , and havent seen a failure yet. I am thinking about trying phelonic. Have tried both a phelonic ring and no ring at the jb joint, always a 3/8 10 pin. Always interesting stuff coming out of Mr Webb. Great info mike

Good stuff Mike. I bought some of the spectraply too. Got some ideas for it. Phenolic is great stuff. Thread them if you can. You'll be happy you did in the long run. If you can't live thread use split dies. They are a great option.