You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is a stacked leather wrap??

- Thread starter bbb

- Start date

It's strips of leather installed around a cue in a fashion similar to a linen wrap. If done properly it feels like solid leather but with more options in patterns/color combos. If done poorly it feels like beef jerky wrapped around a cue.

It is a spirally wrapped thin leather lace...it is an imitation of stacked leather as is found on things like knife handles. Stacked leather handle examples link

Stacked leather handle cue: http://www.youtube.com/watch?v=EteSBoXm9bI

I have only once seen a real stacked leather wrap on a cue and it was in this forum. Nobody seems to have pursued it though as I have not seen it done again.

.

Stacked leather handle cue: http://www.youtube.com/watch?v=EteSBoXm9bI

I have only once seen a real stacked leather wrap on a cue and it was in this forum. Nobody seems to have pursued it though as I have not seen it done again.

.

It is a spirally wrapped thin leather lace...it is an imitation of stacked leather as is found on things like knife handles. Stacked leather handle examples link

Stacked leather handle cue: http://www.youtube.com/watch?v=EteSBoXm9bI

I have only once seen a real stacked leather wrap on a cue and it was in this forum. Nobody seems to have pursued it though as I have not seen it done again.

.

Real stacked leather would be amazing, probably woundnt thick as the knife makers use but thick enough so its a "real" stacked leather, not a old shoe lace wrapped around a butt and finished to appear to look like something it isn't.

Real stacked leather would be amazing, probably woundnt thick as the knife makers use but thick enough so its a "real" stacked leather, not a old shoe lace wrapped around a butt and finished to appear to look like something it isn't.

Well, it was done, and posted in this forum. I'll see if I can dig it up.

Here it is:

http://forums.azbilliards.com/showthread.php?t=250248

.

Last edited:

mohler

Registered

Here are some of the stacked leather handles I've made. The 2 black ones have 70, 1/4" rings , about 17" total. When put on the core,then compressed to a 12" handle they are about as hard as wood. The brown one was done with less rings and not compressed enough, so it had a little chipping on the edges between rings. This one is going to be redone. I also thought it might look nice with thinner rings at each end, wrong. When it gets redone they will all be the same thickness.

Attachments

Are the forearm and butt where the pressure ends up from compressing the rings on the handle?

mohler

Registered

The rings are put on the 3/4 " id core, glued & compressed on the lathe and left to dry. When then put together with the forearm & butt sleeve there isn't any more pressure on those joints than normal. It's compressed hard enough that there isn't any vibration, or wobbly. It feels like any other type handle.

mohler

Registered

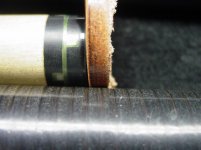

That inside diameter you see on the individual ring is decieving. After installed,the OD is much larger the the final OD of the cue, a lot of that is turned off.The final OD is about where the red circle is or this pictire. I cut them much bigger than needed because there easier to cut without distorting the leather.

Attachments

I've seen this technique on knives and fishing rods, but yours are the first cues I've seen it on. Do you have a website?

The stacked handle has been used for many years in the knife making industry, and Ka-Bar was a classic example. There's a couple things that I would throw out there.... just food for thought, which may or may not have any bearing on cues

EVERY stacked leather handle that I have redone has had a rusted tang on the inside. The leather retains moisture, and so over time it rusts the tang of the blade. (there are pics on my website if you want examples) It's the same reason you wouldn't store your knife in it's sheath....moisture.

The compressed rings used for knife handles are also usually soaked in epoxy once close to final size.....You see that a lot with leather, paracord, jute, etc....

In the last few years we started to see Ka-Bar's with a Kraton "synthetic" handle, which isn't supposed to be slippery when wet, like the leather handle. So I dunno how much of that pertains to cues, but either way it sure is a nice a look when finished out ...

EVERY stacked leather handle that I have redone has had a rusted tang on the inside. The leather retains moisture, and so over time it rusts the tang of the blade. (there are pics on my website if you want examples) It's the same reason you wouldn't store your knife in it's sheath....moisture.

The compressed rings used for knife handles are also usually soaked in epoxy once close to final size.....You see that a lot with leather, paracord, jute, etc....

In the last few years we started to see Ka-Bar's with a Kraton "synthetic" handle, which isn't supposed to be slippery when wet, like the leather handle. So I dunno how much of that pertains to cues, but either way it sure is a nice a look when finished out ...

Last edited:

mohler

Registered

The downside is it adds about 3 hours to the build time, over a standard wrapped handle. And if it ever got damaged the cue would have to be cut apart and rebuilt. The advantage is if it gets a little dull and worn looking , just dye it again, polish it again with atom wax and it looks like new.

The downside is it adds about 3 hours to the build time,

Well...that makes it a "legitimately more expensive" option then. That's how I see it.

Damage would require rebuilding the handle, yes. But as you said it can be refinished fairly easily.

.

My favorite American Made hammer company still uses a stacked leather on their handtools...

http://www.estwing.com/ao_leather_black_eagle_tomahawk.php

JV

http://www.estwing.com/ao_leather_black_eagle_tomahawk.php

JV

My favorite American Made hammer company still uses a stacked leather on their handtools...

http://www.estwing.com/ao_leather_black_eagle_tomahawk.php

JV

Makes me remember my grandfather's hammer.

.

My favorite American Made hammer company still uses a stacked leather on their handtools...

http://www.estwing.com/ao_leather_black_eagle_tomahawk.php

JV

Learned all about them on "How it's made"